A hybrid hoisting hydraulic system and a crane using the same

A hydraulic system, a hybrid technology, applied in hoisting devices, clockwork mechanisms, mechanical equipment, etc., can solve the problems of reduced reliability of hydraulic components, failure to meet the use requirements, and failure to meet energy saving and emission reduction, etc., to achieve power reduction Output, flexible control scheme, and less system pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

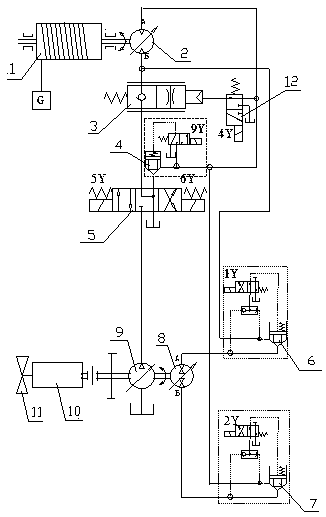

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

[0028] Special Note: The balance valve is a pressure control valve that maintains back pressure to prevent the load from falling freely. It is usually used to prevent the motor or hydraulic cylinder from falling at high speed due to the weight of the load; the balance valve widely used in the field of construction machinery is generally forward-conducting , Reverse proportional throttling speed regulation.

[0029] Closed circuit: When the circuit is working, most of the oil in the pipeline is recycled in the system, and only a small amount of hydraulic oil is sucked from the oil tank by the charge hydraulic pump into the system to realize the cooling of the system oil, Oil replenishment, this oil circuit structure is called a closed circuit.

[0030] Such as figure 1 Shown: the present invention discloses a hybrid winch hydraulic system, which includes:

[0031] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com