A kind of graphene composite coating and preparation method thereof

A graphene composite, graphene technology, used in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of low bonding strength, inability to be widely used, opacity, etc. Chemical stability, good dispersibility and chemical stability, remarkable effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The embodiment of the present invention provides a kind of preparation method of graphene composite coating, it comprises the steps:

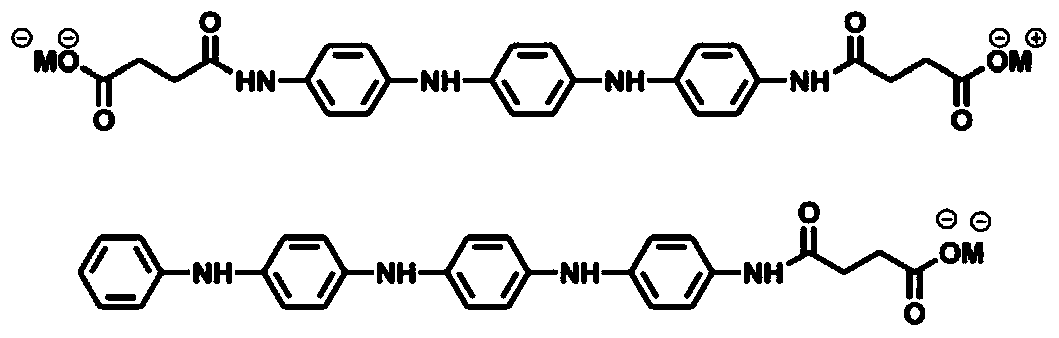

[0022] Step (1): The aniline oligomer derivative and the dispersion medium are mixed to obtain a mixture A. The aniline oligomer derivative has good solubility and can be dissolved in the dispersion medium. The aniline oligomer derivatives are used to modify the graphene. The aniline oligomer derivatives are aniline oligomers with functional groups, and the functional groups include carboxyl groups, alkyl groups, sulfonic acid groups, phosphoric acid groups, epoxy groups, polyethylene glycol groups and / or polyvinyl alcohol group. Preferably, the aniline oligomer is one or a combination of aniline trimer, aniline tetramer, aniline pentamer, aniline hexamer, aniline octamer.

[0023] The aniline oligomer or derivative thereof may have the following structural formula:

[0024]

[0025] (M is mainly sodium ion, potassium ion, quatern...

Embodiment 1

[0040] First, 10 g of aniline trimer and 80 g of deionized water were stirred and dispersed at a high speed of 1500 rad / min for 10 min to obtain mixture A. Add 10 g of single-layer graphene powder into the mixture A, continue high-speed stirring for 20 minutes and sonicate for 10 minutes to obtain a uniform and stable graphene dispersion.

[0041] Add 60g of silicone resin into a stirring container, then add 35g of the graphene dispersion under the condition of high-speed stirring at 1500rad / min, and stir evenly to obtain mixture B. Then add 2g ethylene glycol monobutyl ether, 2g lauryl sulfate, 0.5g modified mineral oil and 0.5g silicone oil to the mixture B, continue to stir for 10min and ultrasonically disperse for 30min, and filter through a 325-400 mesh screen , to obtain the graphene composite coating.

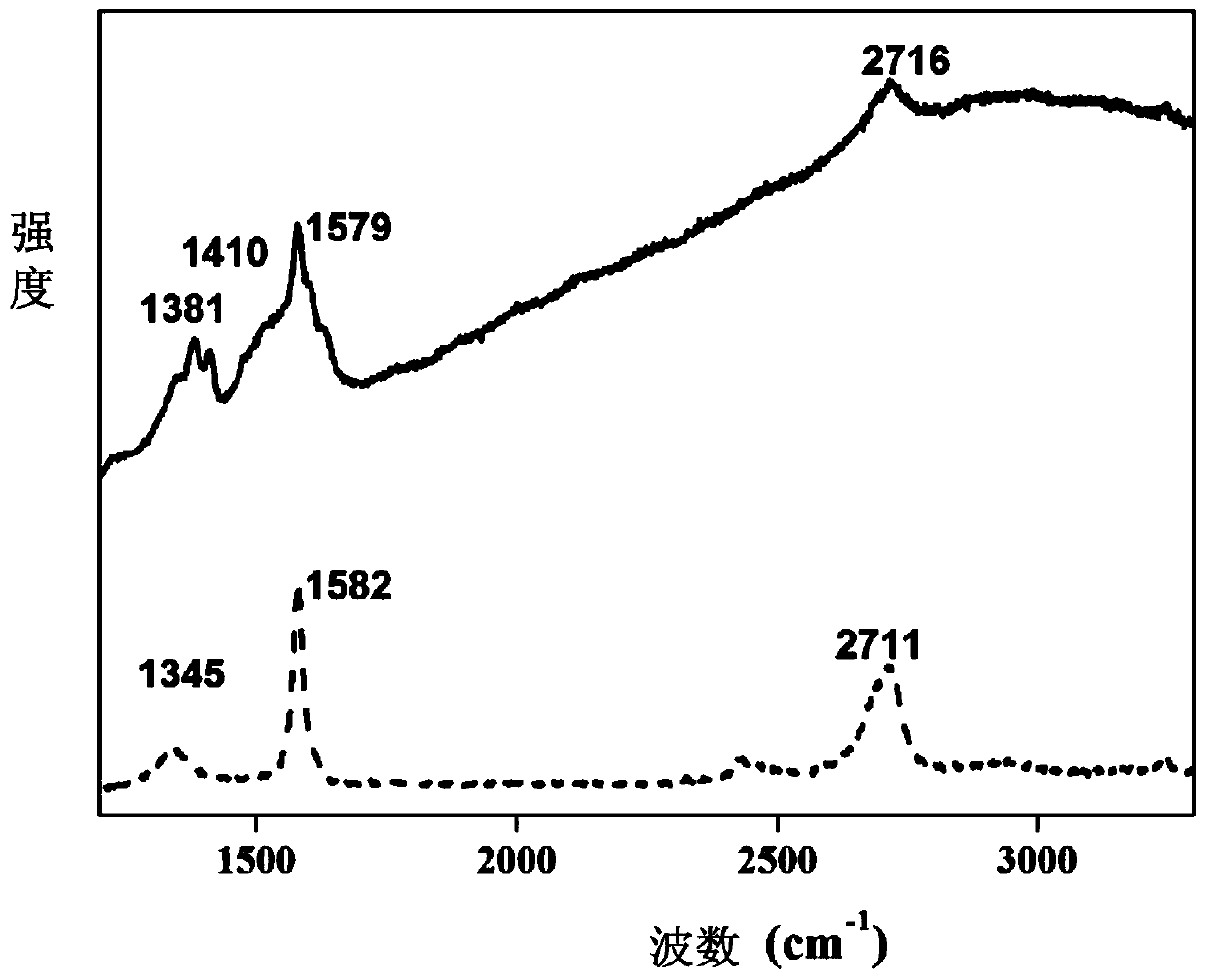

[0042] For the dispersion effect of the graphene dispersion, please refer to figure 1 . Depend on figure 1 It can be seen that the dispersion effect of the graphene ...

Embodiment 2

[0052] First, 9.9 g of aniline tetramer and 90 g of ethanol were dispersed under high-speed stirring at 1500 rad / min for 10 min to obtain mixture A. Then add 0.1 g of multi-layer graphene powder into the mixture A, continue to stir at high speed for 20 minutes and ultrasonically for 10 minutes to obtain a uniform and stable graphene dispersion.

[0053] Add 52g of acrylic resin into a stirring container, then add 45g of the graphene dispersion under the condition of high-speed stirring at 1500rad / min, and stir evenly to obtain a mixture B. Then add 1g of dipropylene glycol methyl ether ethyl ether ester, 1g of dodecylsulfonate, 0.5g of simethicone and 0.5g of hydroxymethyl cellulose to the mixture B, continue to stir for 10min and ultrasonically disperse for 30min, after 325-400 Mesh sieve filter treatment, namely obtain graphene composite coating.

[0054] For the dispersion effect of the graphene dispersion, please refer to figure 1 . Depend on figure 1 It can be seen th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com