Manufacturing process for weaving mini-jacquard and large-pattern clothing plain velvet fabric by adopting double-rapier loom

A technology of double rapier looms and large jacquard flowers is applied in the direction of excavated fabrics, fabrics, embossed fabrics, etc., which can solve the problems of high cost and complicated process, and achieves increased colors and varieties, clear yarn paths, and uniform tension. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

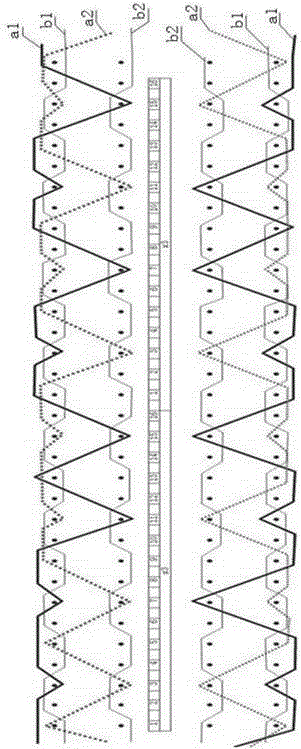

[0014] The technical process and specific implementation methods of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] A manufacturing process for weaving small jacquard and large pattern garment velveteen fabrics using double rapier looms, using double-layer rapier looms as processing tools, using cotton yarn and polyester-cotton yarn as raw materials, through raw material processing, warping, weaving, It is woven by brush hair and dyeing process, and its manufacturing process includes the following steps:

[0016] The first step of raw material processing: 50S / 2 pure cotton yarn and 50S / 2 polyester-cotton yarn are used as raw materials. In order to distinguish the two yarns, the polyester-cotton yarn is dyed with food coloring that can be removed by washing. After dyeing, the coloring of polyester and cotton is inconsistent, forming different texture effects; but the dyeing effect cannot affect the finishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com