Spiral packer rubber barrel with steel skeleton

A spiral and packer technology, which is applied in sealing/packing, wellbore/well components, earthwork drilling and production, etc., can solve problems such as inability to achieve effective sealing, tearing of rubber tubes, and affecting sealing performance, and achieve increased Effects of sealing area and stability, increased contact length, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

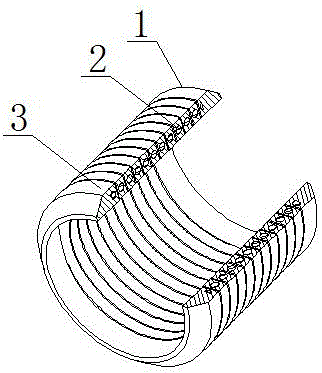

[0016] The spiral packer rubber cartridge with steel skeleton includes a rubber cartridge body 1; the rubber cartridge body 1 is cylindrical, and the rubber cartridge body 1 is provided with a helical pattern 3, and the helical pattern 3 of the rubber cartridge body 1 is wrapped with a helical spring 2. The coil spring 2 is a steel coil spring. The coil spring 2 is a single-wire spring or a double-wire spring or a multi-wire ring spring.

[0017] The rigidity of the helical spring 2 of the rubber cartridge of the spiral packer is greater than the rigidity of the rubber cartridge body 1 .

[0018] When the rubber cartridge of the spiral packer is installed and used, the rubber cartridge body 1 is wrapped on the outer shaft of the packer, and is lowered to a designated position together with the packer and casing during the working process. When setting, the packer applies pressure to the end of the rubber tube body 1, and the coil spring 2 is compressed synchronously with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com