Stuck machine extricating method for tunnel boring machine (TBM) during construction

A technology for roadheaders and tunnels, which is applied in tunnels, earth-moving drilling, mining equipment, etc., can solve problems such as affecting the construction period of tunnels, and achieve the effect of reducing engineering costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

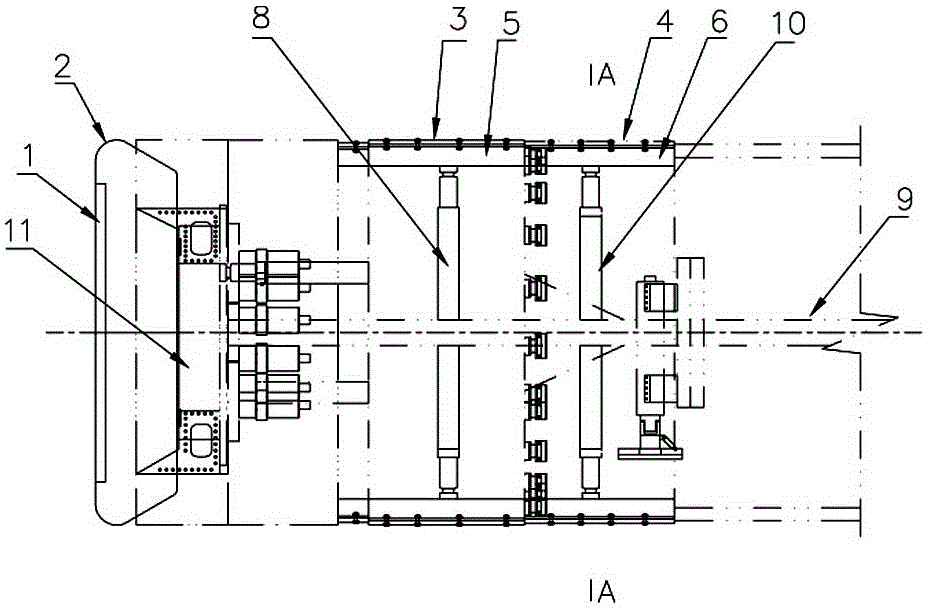

[0020] like Figure 1-6 As shown, the method for getting rid of the stuck machine during the construction of the tunnel boring machine of the present invention is carried out according to the following steps:

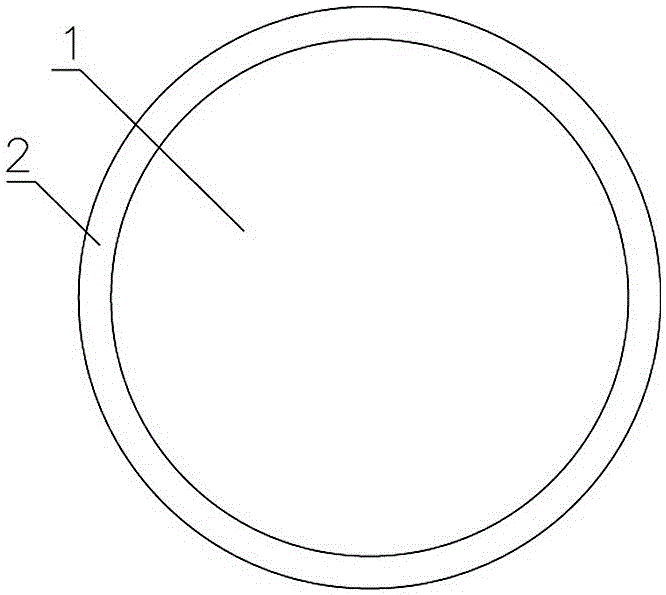

[0021] The first step is to set the cutter head of the tunnel boring machine to be composed of a central circular panel 1 and a side panel 2 welded along the outer edge of the central circular panel 1; the diameter of the side panel 2 is equal to the tunnel excavation diameter, and the central circular panel 1 The diameter is smaller than the tunnel design diameter;

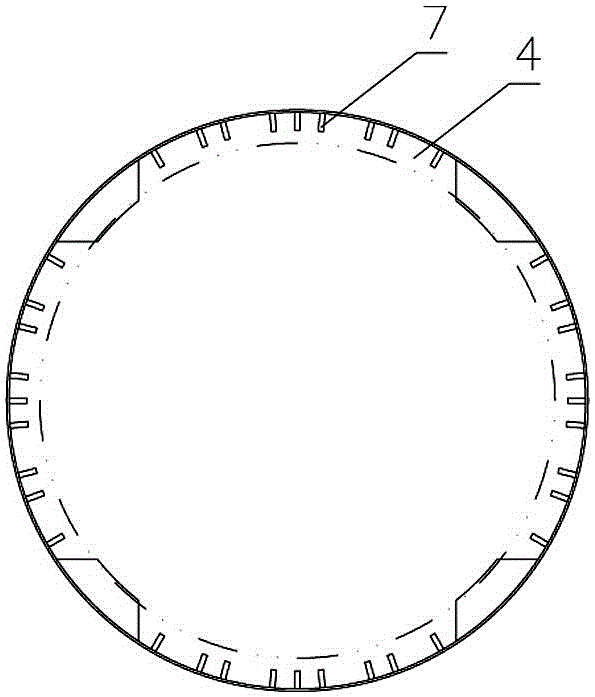

[0022] In the second step, the shield of the tunnel boring machine adopts an inner and outer two-layer structure arranged along the radial direction. The boot shield 5 and the inner tail shield 6 are composed; the outer boot shield 3 and the inner boot shield 5, the outer tail shield 4 and the inner tail shield 6 are respectively connected by bolts 7; the outer shield The diameter is smaller than the exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com