An Anti-rotation Piston Linear Motion Pair in Engineering Application of Large-Scale Offshore Devices

A linear motion pair, engineering application technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of inconsistent radial direction between the piston and the cylinder, difficult processing of the inner wall of the cylinder, etc., to improve reliability and corrosion resistance, Save machining costs and time, and eliminate pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

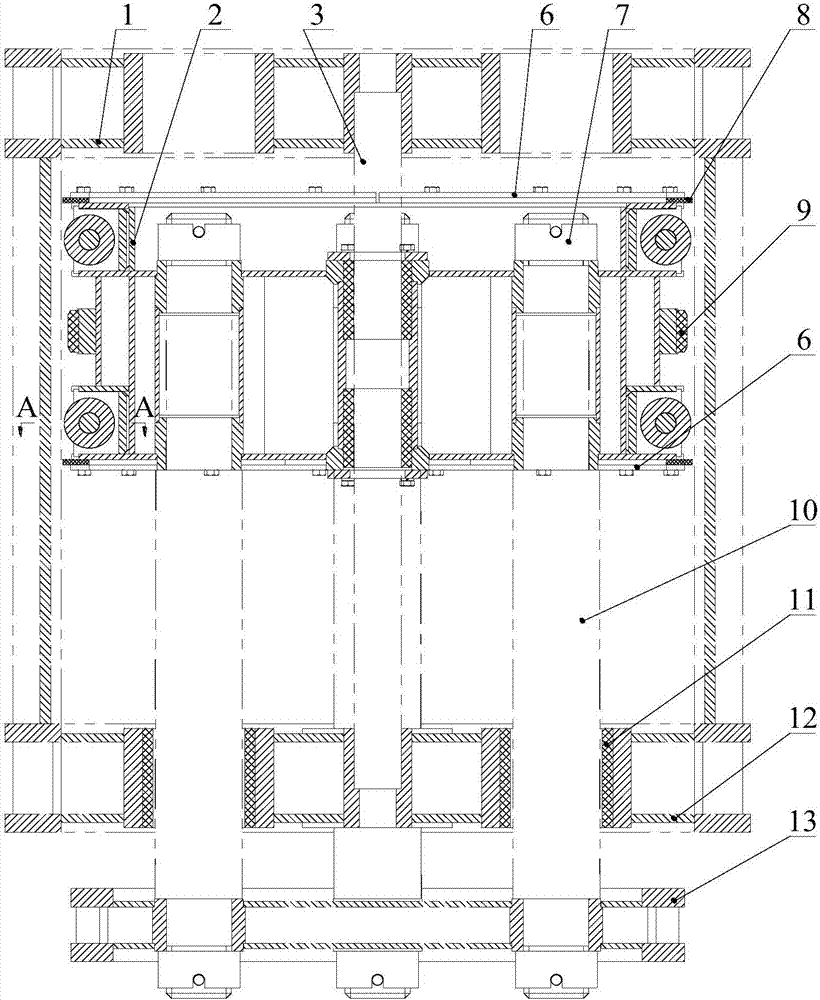

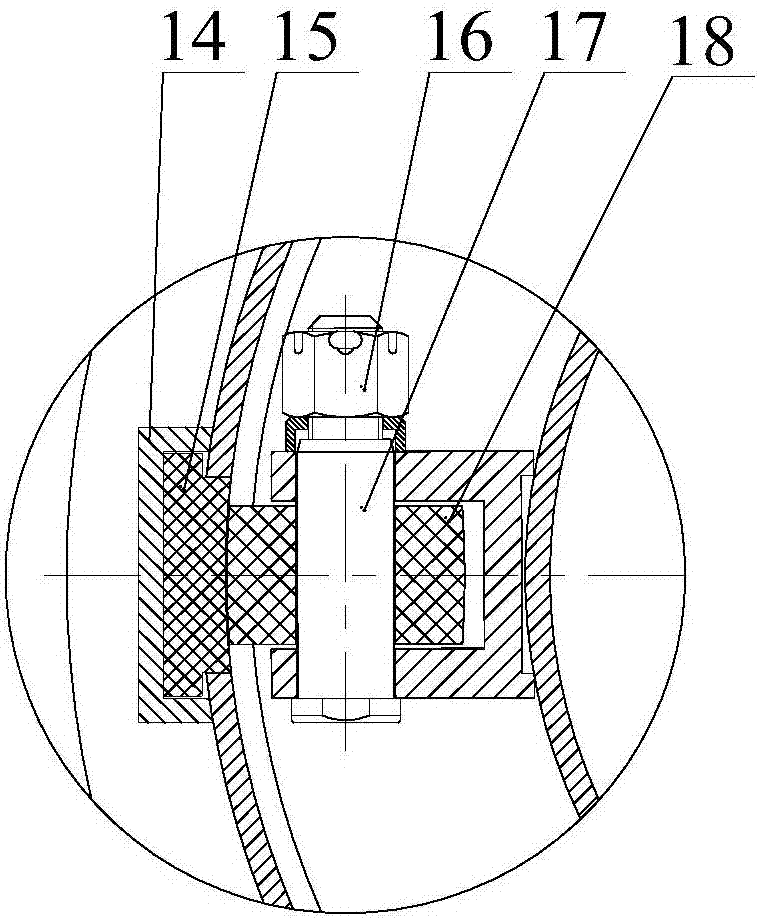

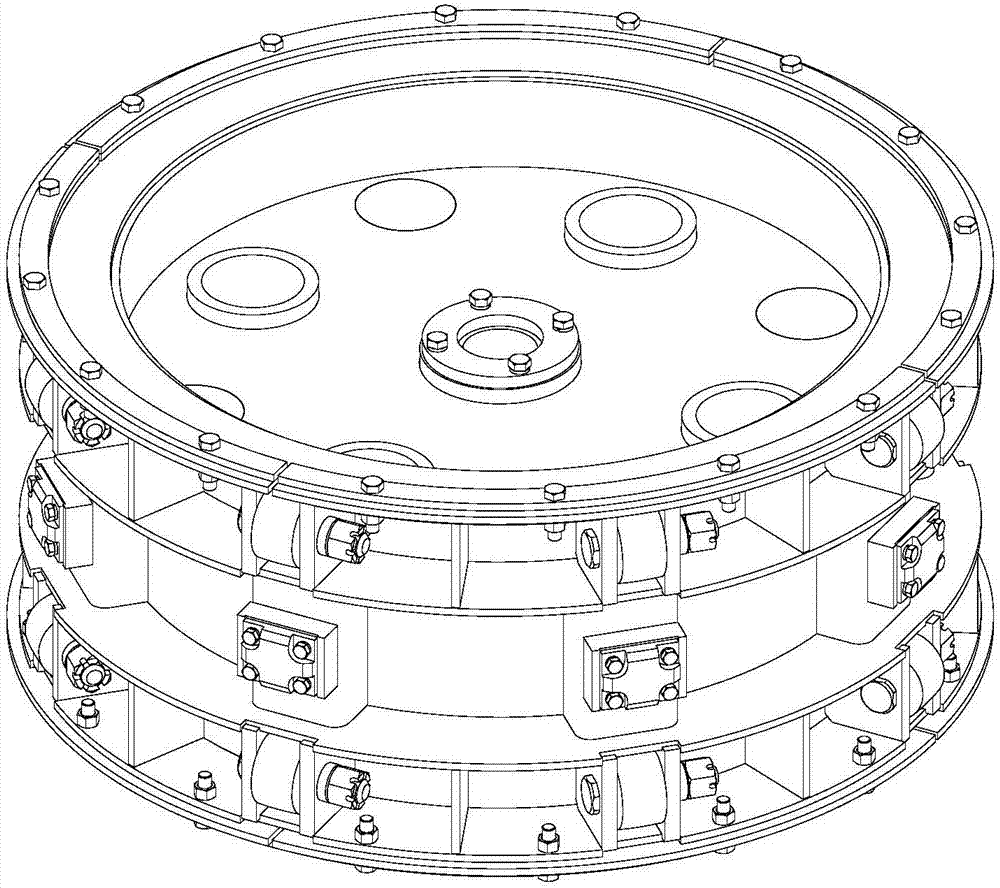

[0019] like Figure 1 to Figure 3 The anti-rotation piston linear motion pair in the engineering application of a large-scale marine device is shown, including the cylinder upper frame 1, the piston base 2, the central guide shaft 3, the arc-shaped pressure plate 6, the arc-shaped sealing blade 8, the pull shaft 10, The cylinder lower frame 12, the connecting frame 13, the nut 16, the pin shaft 17, and the roller 18; the cylinder upper frame 1 and the cylinder lower frame 12 are connected up and down to form a cylinder, and the cylinder upper frame 1 and the cylinder lower frame The central position between the frames 12 is fixed with a central guide shaft 3, and the central guide shaft 3 passes through the center position of the end faces of the two ends of the piston base body 2; the two ends of the piston base body 2 are fixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com