Efficient battery material sintering furnace with push plate guide sliding function

A technology of guided sliding and battery materials, applied in the direction of furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of damage to the bottom wall of the furnace, cracks and collapse of the upper partition beam, and achieve side wall protection, good sliding performance, The effect of reducing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

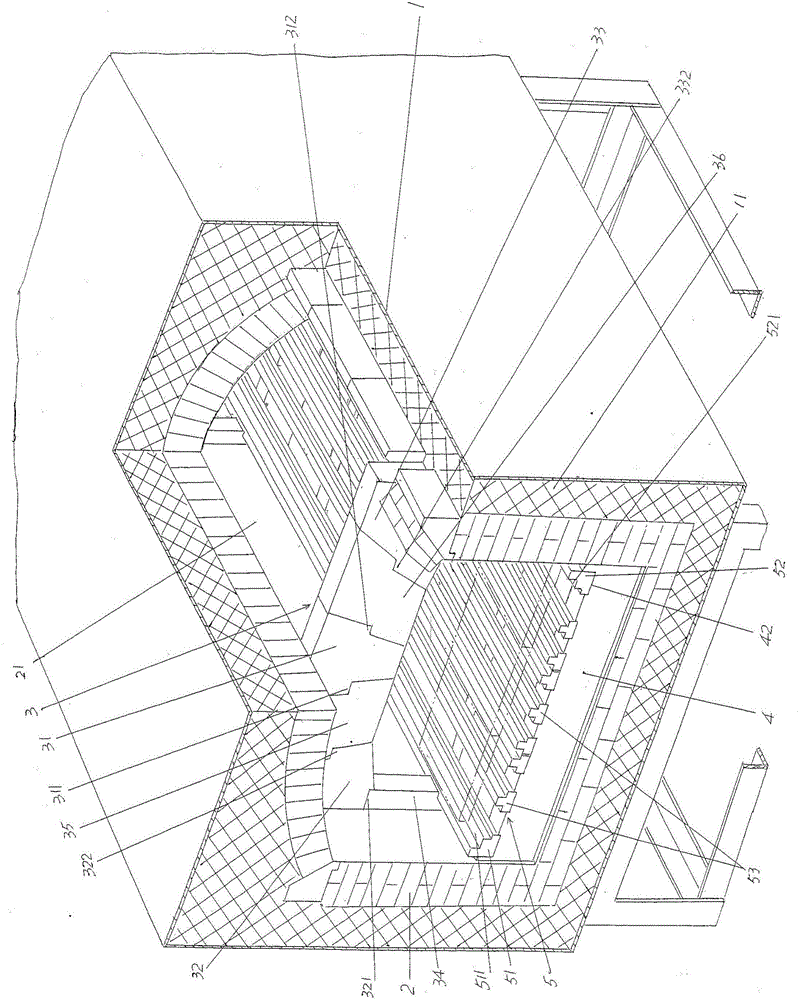

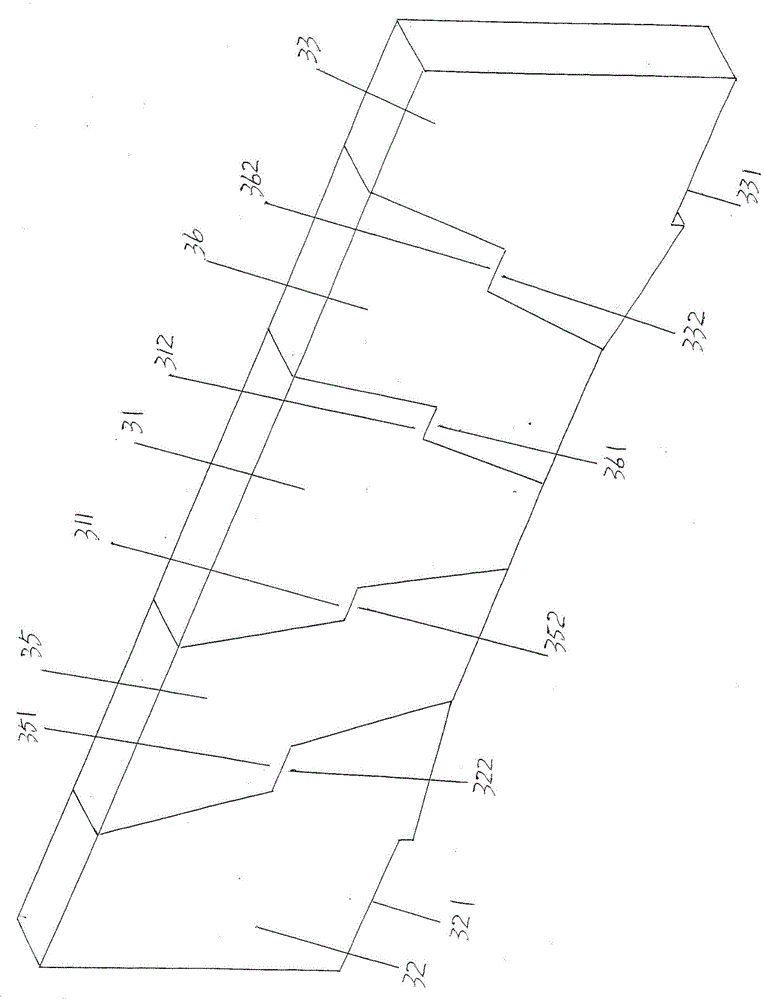

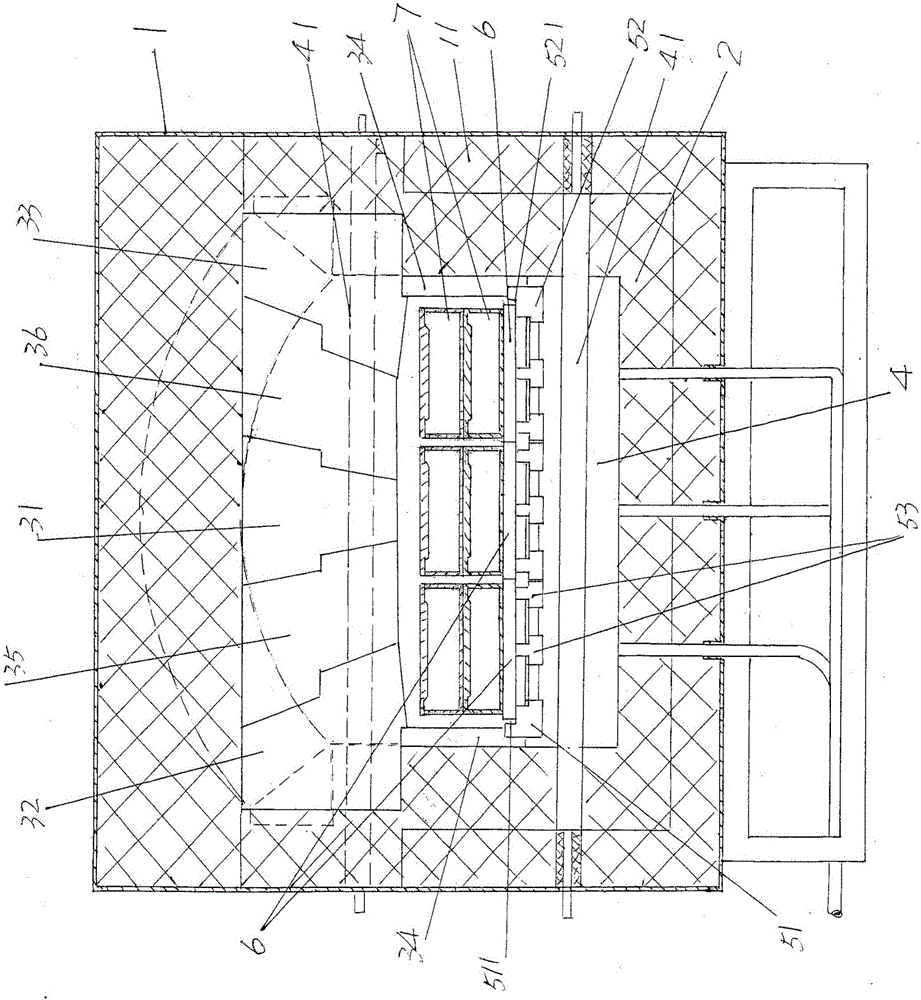

[0025] See figure 1 with figure 2 , shows the furnace shell 1, a furnace pad 11 is arranged around the inner wall of the furnace shell 1, shows a furnace lining 2, an upper partition beam 3 and a group of lower partition beams 4, and the furnace lining 2 surrounds the inner wall of the aforementioned furnace pad 11 It is arranged around (up, down, left, and right), and the space formed by the furnace lining 2 is formed as a furnace chamber 21. The upper partition beam 3 is arranged corresponding to the top of the furnace chamber 21 and is in contact with the top of the aforementioned furnace lining 2. A set of lower partition beams 4 are arranged at the bottom of the aforementioned furnace lining 2 in a spaced state.

[0026]As the technical points of the technical solution provided by the present invention: the structural system of the aforementioned high-efficiency sintering furnace for battery materials also includes a push plate guiding sliding mechanism 5, which include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com