Mercaptoethyl dioleate dimethoxycarbonylethyl tin compound and preparation method thereof

A technology of mercaptoethyl alcohol ester dimethoxycarbonylethyltin and dichlorodimethoxycarbonylethyltin, which is applied in the field of Youji tin compound and its preparation, can solve the problems of insufficient raw material sources and high cost, and achieve high efficiency High, excellent lubricity, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

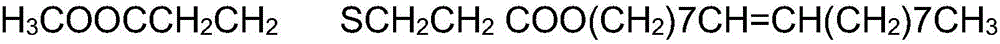

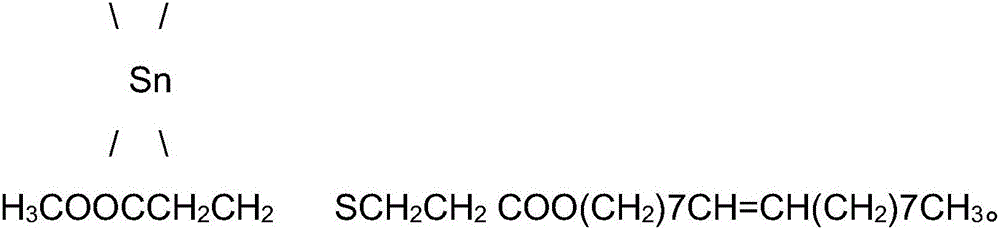

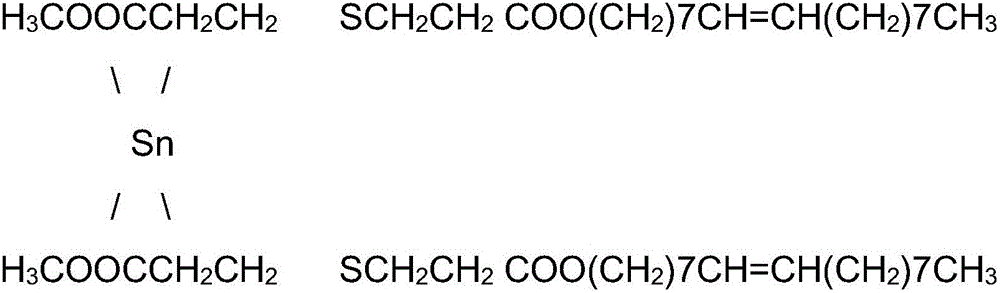

[0052] Prepare the mercaptoethyl alcohol dioleate dimethoxycarbonyl ethyl tin compound of the following molecular formula:

[0053]

[0054]

[0055] Prepare as follows:

[0056] A, the preparation of dichlorodimethoxycarbonyl ethyl tin compound intermediate

[0057] Sn+2CH 2 =CHCOOCH 3 +2HCL→(CH 3 COOCCH 2 CH 2 )2SnCL 2

[0058] With 92 kilograms of methyl acrylate (content: 99.0%, technical grade), 2 kilograms of concentration are the concentrated hydrochloric acid of 31% and 0.5 kilogram of catalyst AlCl 3 Put it into the chlorinated enamel reaction kettle, start stirring, and add 60 kg of tin powder (content: 99.99%, industrial grade, mesh number: 400 mesh) while stirring, and feed 37 kg of dry hydrogen chloride gas at the same time. At the bottom of the reaction kettle, in order to increase the reaction speed, the reaction temperature is controlled at 60°C, and the reaction time is 3 hours. After the tin powder is completely reacted (take a sample to observe...

Embodiment 2

[0069] Prepare the mercaptoethyl alcohol dioleate dimethoxycarbonyl ethyl tin compound of the following molecular formula:

[0070]

[0071] Prepare as follows:

[0072] A, the preparation of dichlorodimethoxycarbonyl ethyl tin compound intermediate

[0073] Sn+2CH 2 =CHCOOCH 3 +2HCL→(CH 3 COOCCH 2 CH 2 )2SnCL 2

[0074] With 65 kilograms of methyl acrylate (content: 99.0%, industrial grade), 1 kilogram of concentration is the concentrated hydrochloric acid of 31% and 0.3 kilogram of catalyst AlCl 3 Put it into the chlorinated enamel reaction kettle, start stirring, and add 50 kg of tin powder (content: 99.99%, industrial grade, mesh number: 400 mesh) while stirring, and at the same time pass 30 kg of dry hydrogen chloride gas into the At the bottom of the reaction kettle, in order to increase the reaction speed, the reaction temperature is controlled at 50°C, and the reaction time is 2.5 hours. After the tin powder is completely reacted (take a sample to observe th...

Embodiment 3

[0084] Prepare the mercaptoethyl alcohol dioleate dimethoxycarbonyl ethyl tin compound of the following molecular formula:

[0085]

[0086] Prepare as follows:

[0087] A, the preparation of dichlorodimethoxycarbonyl ethyl tin compound intermediate

[0088] Sn+2CH 2 =CHCOOCH 3 +2HCL→(CH 3 COOCCH 2 CH 2 )2SnCL 2

[0089] With 115 kilograms of methyl acrylate (content is: 99.0%, industrial grade), 2.8 kilograms of concentrations are the concentrated hydrochloric acid of 31% and 0.9 kilograms of catalyst FeCl 3 Put it into the chlorinated enamel reaction kettle, start stirring, and add 80 kg of tin powder (content: 99.99%, industrial grade, mesh number: 400 mesh) while stirring, and feed 60 kg of dry hydrogen chloride gas at the same time. At the bottom of the reaction kettle, in order to increase the reaction speed, the reaction temperature is controlled at 80°C, and the reaction time is 3 hours. After the tin powder is completely reacted (take a sample to observe th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com