Radiation Curable Optical Fiber Coloring Inks

A coloring ink, radiation curing technology, applied in ink, household appliances, applications, etc., can solve problems such as the inability to meet the requirements of optical fiber coloring inks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

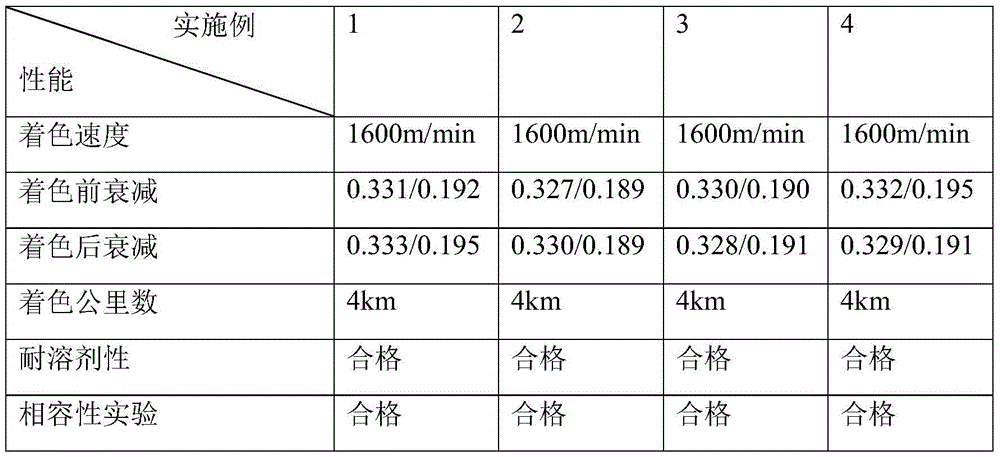

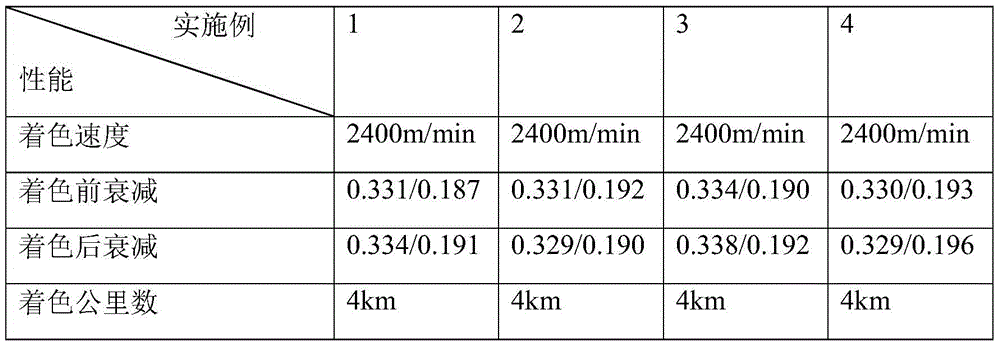

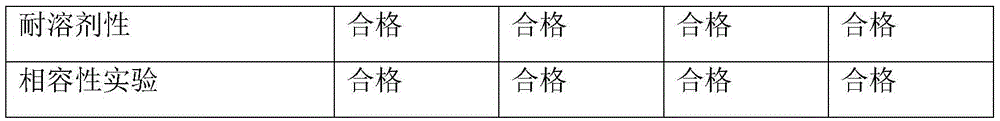

Examples

Embodiment 1

[0045] A radiation-curable white optical fiber coloring ink, the content of its components is as follows: 15% of white color paste, 27.4% of reactive diluent, 45% of UV resin, 3.6% of auxiliary agent, photoinitiator and Coinitiator 9%.

[0046] Among them, the proportion of white color paste is as follows by weight: 50% titanium dioxide, 3% BYK-111, 1% BYK-1790, 10% resin M-512, 36% trimethylolpropane triacrylate, a total of 100%, The specific preparation method is as follows: (1) uniformly mix trimethylolpropane triacrylate, BYK-111 and BYK-1790, and 10% resin M-512 to obtain a mixed liquid component; , adding the pigment titanium dioxide white to the mixed liquid component, after the pigment is added, increase the rotation speed to 1000r / min and stir for 1.0 hour, the obtained UV crude color paste; (2) carry out the UV crude color paste Grind for 25 minutes and use a laser particle size analyzer to measure the fineness. When all pigment particles are measured to be less tha...

Embodiment 2

[0051] A radiation-curable black optical fiber coloring ink, the content of each component is: 10% of black color paste, 24.4% of reactive diluent, 53% of UV resin, 3.6% of auxiliary agent, photoinitiator and Coinitiator 9%.

[0052] Among them, the proportion of black color paste is as follows by weight: 20% carbon black, 18% BYK-163, 1% BYK-1790, 20% resin M-512, 41% trimethylolpropane triacrylate, a total of 100%, Initial fineness D9014.292 micron, final fineness D900.131 micron after grinding for 15min, prepared according to the preparation method of Example 1;

[0053] Wherein, the active diluent, its composition by weight percentage is: 20% (2) propoxylated neopentyl glycol diacrylate, 20% tripropylene glycol diacrylate, 10% dipentaerythritol hexaacrylate, 10% diacrylate - Trimethylol propane tetraacrylate, 25% ethylene glycol phthalate, 15% dipropylene glycol diacrylate; the composition of the UV resin is calculated by weight percentage: 30% self-made polyether polyure...

Embodiment 3

[0057] A radiation-curable red optical fiber coloring ink, the content of each component is as follows: 4% white color paste, 10% red color paste, 25.4% reactive diluent, 50% UV resin, 3.6% auxiliary agent %, photoinitiator and co-initiator 7%.

[0058] Among them, the red color paste is as follows by weight: 20% quinacridone red, 8% BYK-163, 1% BYK-1790, 10% resin M-512, 61% tripropylene glycol diacrylate, a total of 100%, The initial fineness is D9086.654 microns, and the final fineness is D900.215 microns after grinding for 10 minutes; the white color paste is prepared according to the preparation method of Example 1;

[0059] Wherein, the active diluent, its composition by weight percentage is: 20% (2) propoxylated neopentyl glycol diacrylate, 20% tripropylene glycol diacrylate, 10% dipentaerythritol hexaacrylate, 10% diacrylate -trimethylolpropane tetraacrylate, 32% (3) propoxylated trimethylolpropane triacrylate, 8% hexamethylene diacrylate; described UV resin, its comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com