Horizontal intelligent length reference instrument

A technology of length datum and datum, applied in instruments, measuring devices, optical devices, etc., can solve the problems of low precision, cumbersome operation, inaccurate measured data, etc., and achieve the effect of eliminating errors and avoiding errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

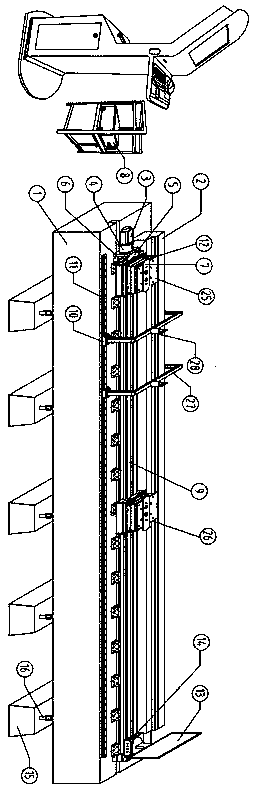

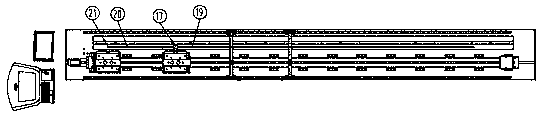

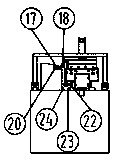

[0036] like Figure 1-3 The horizontal intelligent length reference instrument shown includes the upper computer 8, the main workbench 1, the additional workbench 2 and the screw transmission unit. The main workbench 1 and the additional workbench 2 are made of marble. A marble support 15 is provided, and the marble support 15 is fixedly connected to the main workbench 1 by support bolts 16 .

[0037]The additional workbench 2 and the screw drive unit are installed in parallel on the main workbench 1 respectively. The grating ruler 19 is installed on the additional workbench 2. The grating ruler 19 is pasted on the additional workbench 2. Both ends of the grating ruler 19 are fixed. There is a grating ruler pressing block 21, and the screw drive unit includes a slide rail 9, a lead screw and a screw nut. The head of the slide rail 9 is fixedly equipped with a fixed measuring block 25, and a moving measuring block 26 is slidably installed on the slide rail 9 for fixed measureme...

Embodiment 2

[0062] The intelligent length reference instrument in this embodiment is basically the same as that in Embodiment 1, the difference is that the upper computer adopts an operating system with intelligent human-computer interaction, and the operating system has functions such as guiding the user to establish a length reference and performing automatic error compensation , the operating system of the length reference instrument in the host computer includes the following modules:

[0063] (1) Intelligent guidance module: through the human-computer interaction interface, the user is guided to perform zero calibration at startup, automatically, and guides the user to establish the length reference according to the steps designed by the system;

[0064] (2) Error compensation module: including the grating ruler length automatic correction module and the temperature compensation module; the grating ruler length automatic correction module automatically and synchronously collects the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com