Whole-section flow measurement device for circular pipeline

A flow measuring device and a full-section technology, which is applied in the direction of measuring fluid flow by measuring pressure difference, volume/mass flow generated by mechanical effects, etc., can solve the problems of chaotic arrangement of full-pressure pipes, low accuracy, and easy damage. Achieve stable and reliable use and maintenance, continuous measurement data, and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

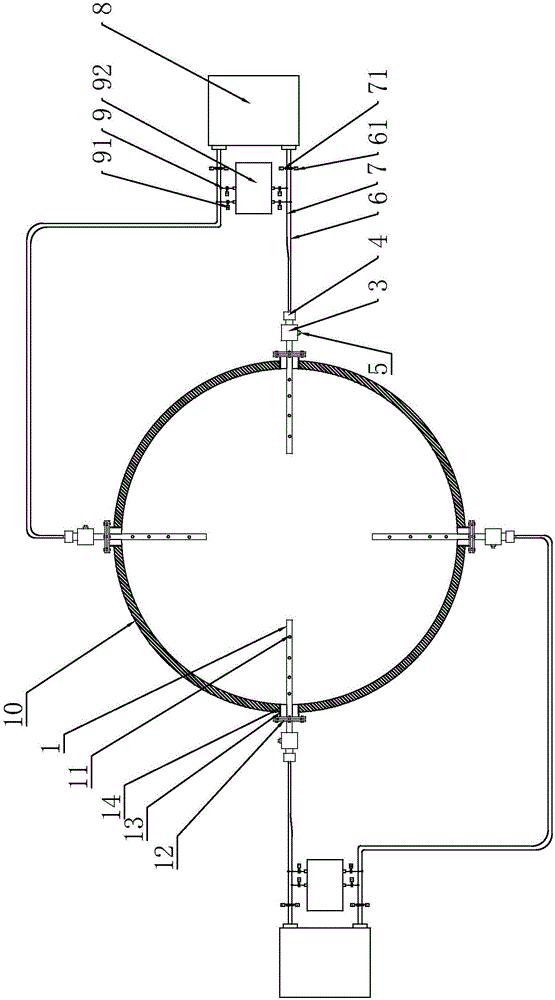

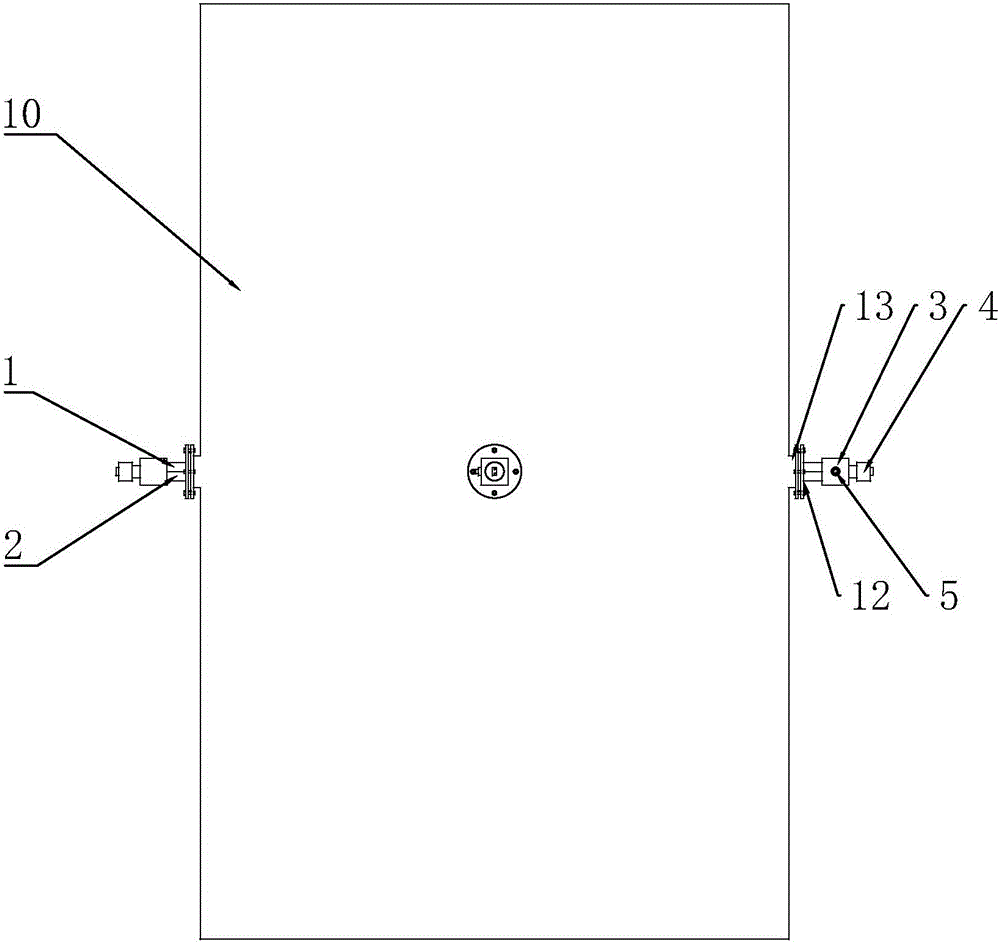

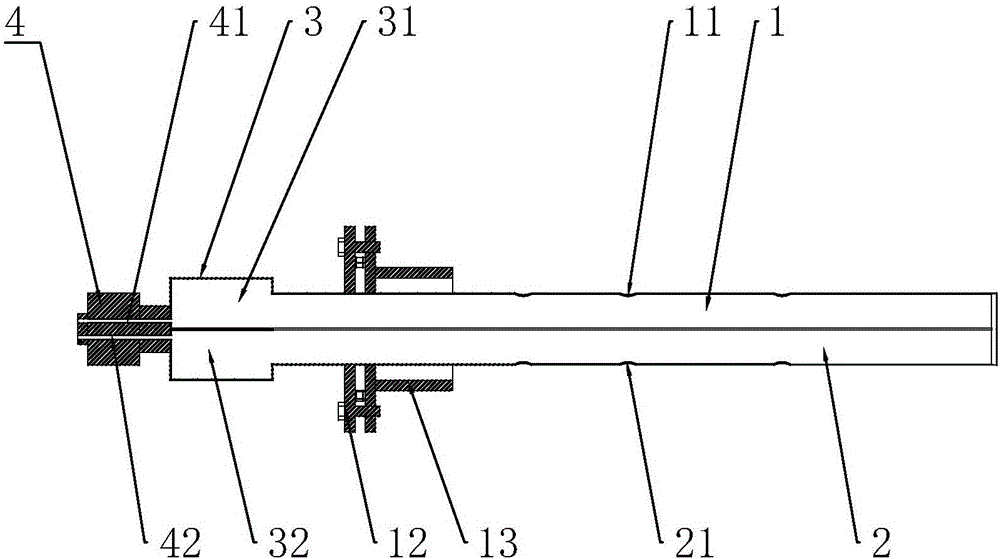

[0017] Such as Figure 1-Figure 3 As shown, the circular pipeline full-section flow measuring device of the present invention includes four groups of sampling tubes arranged orthogonally along the circumference, each group of sampling tubes includes a total pressure tube 1 and a static pressure tube 2, and the total pressure tube 1 and the static pressure tube 2 adopt Stainless steel pipe, total pressure pipe 1 and static pressure pipe 2 are arranged back to back, total pressure pipe 1 is provided with several total pressure sampling holes 11 in the windward direction, and static pressure pipe 2 is provided with several static pressure sampling holes 21 in the opposite direction. The present invention is mainly applicable to circular pipes with an inner diameter of Φ3001mm-Φ8000mm. The number of sampling holes is determined according to the inner diameter of the circular pipe. The larger the inner diameter, the more the number of settings. There are 4 or 5, and the setting pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com