Temperature-strain integrated measuring method in high-temperature tension test

A measurement method and grayscale technology, applied in thermometers, heat measurement, measuring devices, etc., can solve the problems of result influence, decorrelation effect cannot be measured, and use temperature cannot be reached, so as to overcome the influence of environmental factors and avoid definite emission Rate, to achieve the effect of strain measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

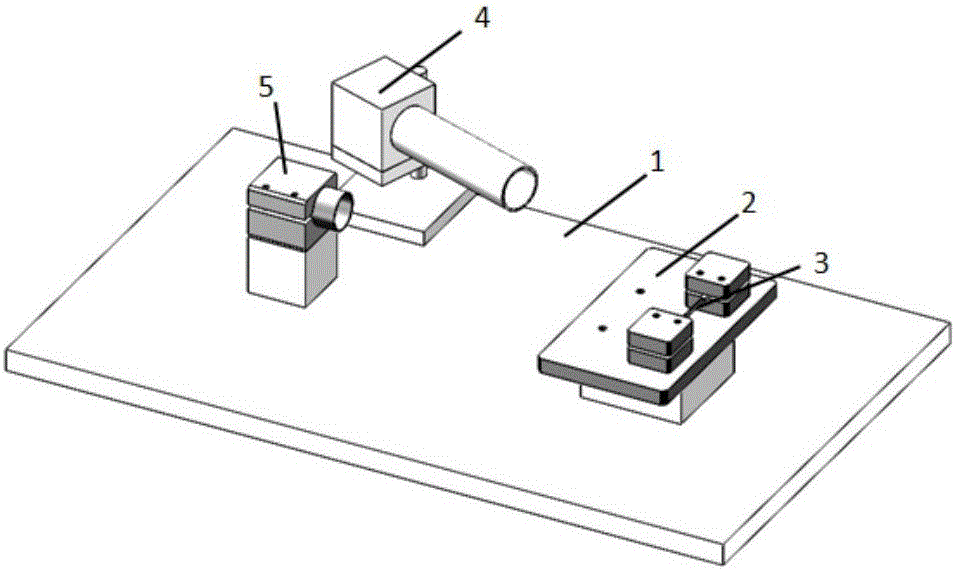

[0034] figure 2 In the process, fix the test piece support platform 2, industrial camera 4, and two-color thermometer 5 on the base plate 1, and install the test piece 3 on the support platform 2; adjust the positions of the industrial camera 4 and the two-color thermometer 5, so that the industrial The field of view of the camera 4 and the temperature measurement point of the two-color thermometer 5 are located on the test piece 3 . The industrial camera 4 is directly connected to the computer, and its acquisition rate is controlled by software, and the acquisition rate is set at 1S / s; the two-color thermometer 5 is connected to the computer through an acquisition card, and the acquisition rate is set at 10S / s.

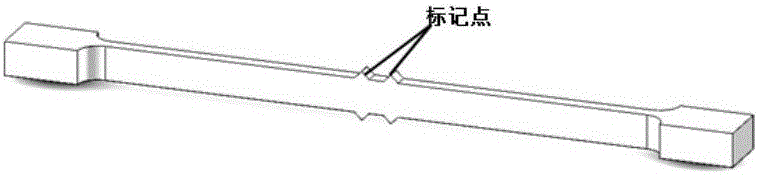

[0035] After the experimental equipment is ready, the gray scale calibration is carried out first: the test piece is heated with a high-power DC power supply, and when the temperature reaches 1000°C, the two-color thermometer starts to record the temperature data, a...

Embodiment 2

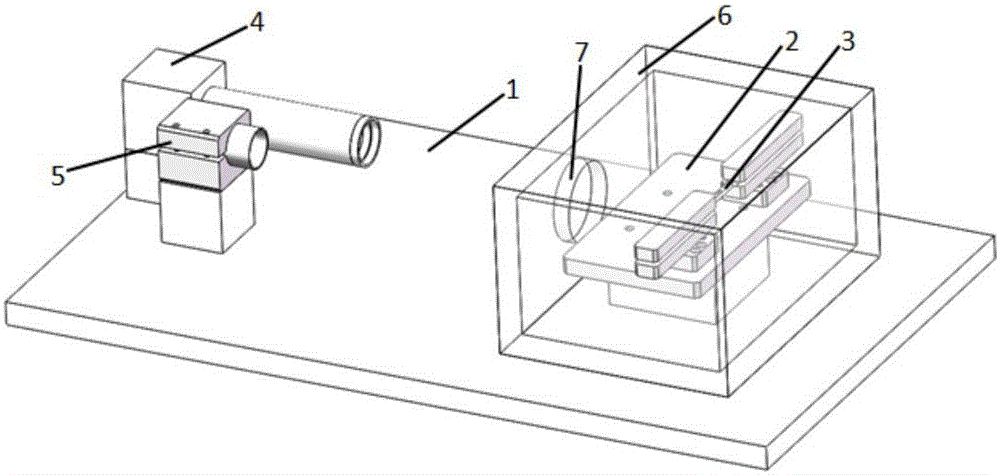

[0038] image 3 Among them, the vacuum box 6, the industrial camera 4, and the two-color thermometer 5 are fixed on the bottom plate 1, the test piece support table 2 is fixed in the vacuum box 6, and the test piece 3 is installed on the test piece support table 2. The industrial camera 4 and the two-color thermometer 5 observe the test piece located inside the vacuum box 6 through the observation window 7, and adjust the positions of the industrial camera 4 and the two-color thermometer 5 so that the field of view of the industrial camera 4 and that of the two-color thermometer 5 The temperature measuring point is located on the test piece. The industrial camera 4 is directly connected to the computer, controls its acquisition rate by software, and directly stores the collected images in the computer; the two-color thermometer 5 is connected to the computer through the acquisition card, and the acquisition card directly controls the temperature acquisition rate, and Store th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com