Silicon-glass-silicon structure surface acoustic wave temperature and pressure integrated sensor and preparation thereof

A technology integrating sensors and temperature sensors, applied in the field of sensors, can solve problems affecting sensor life and measurement accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

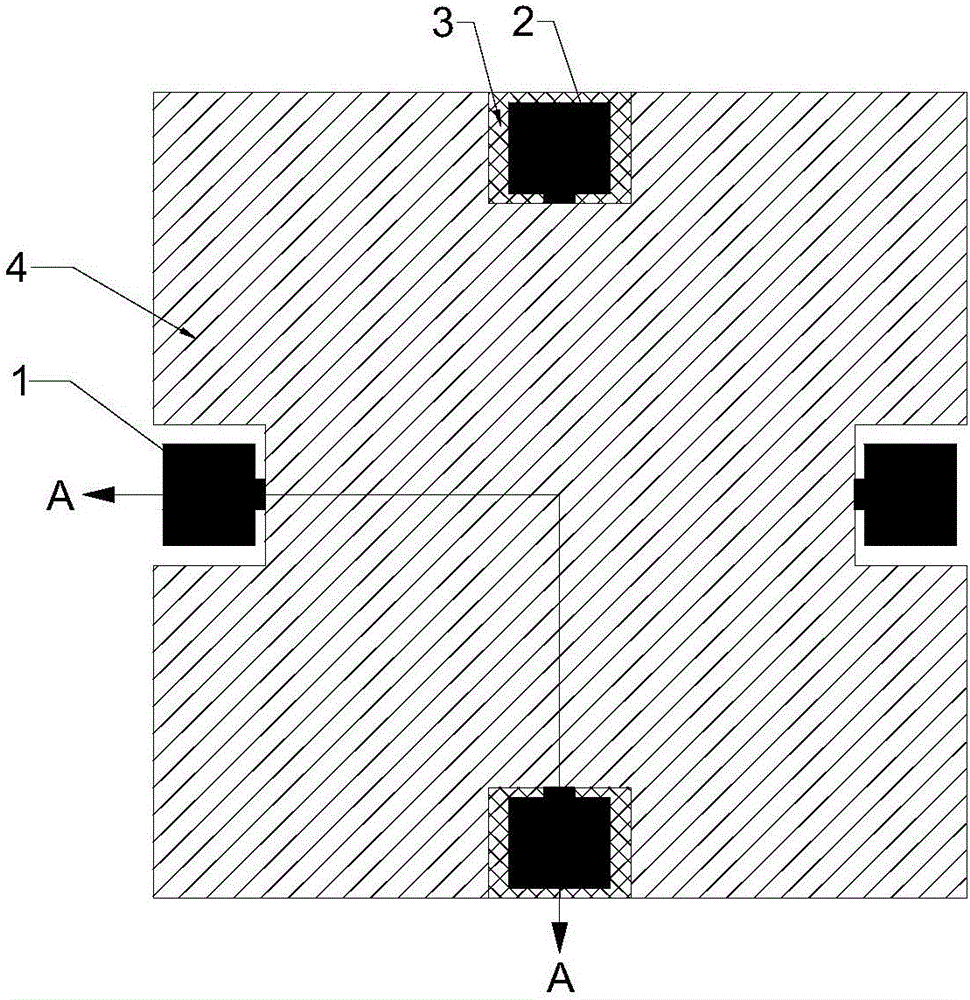

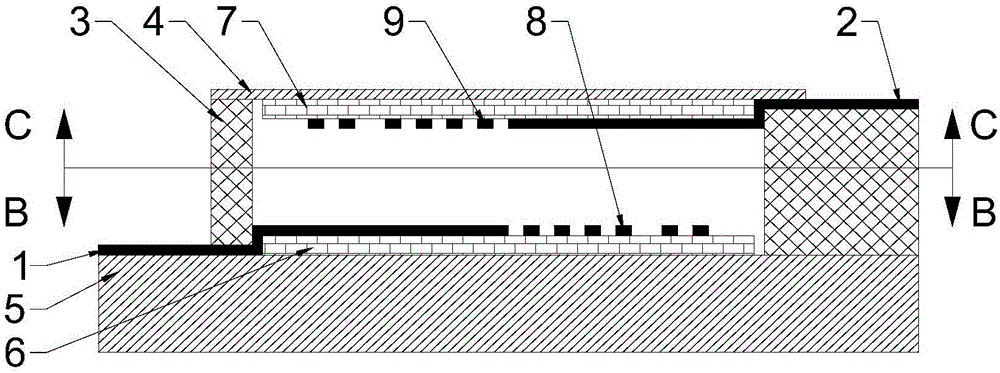

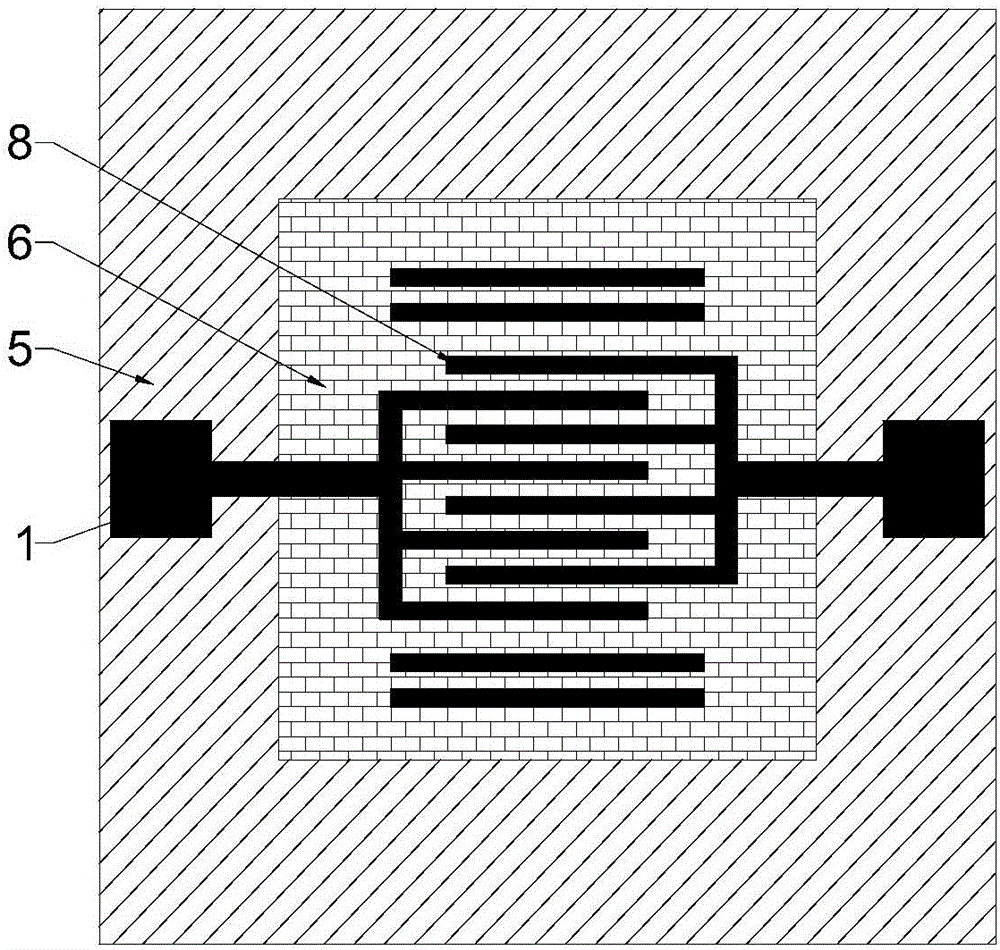

[0035] Such as Figure 1~5 As shown, the present invention proposes a surface acoustic wave temperature and pressure integrated sensor with a silicon-glass-silicon structure. The main body of the chip is a sandwich structure, and the main body of the sensor is provided with a silicon substrate, a glass frame and a silicon-based pressure-sensitive film; A surface acoustic wave temperature sensor is made by layering metal interposer transducers, reflective grids and extraction electrodes; the glass frame is composed of glass, the bottom is bonded to the silicon substrate, and the top is bonded to the silicon-based pressure-sensitive film to form a cavity. The surface acoustic wave temperature sensor and the surface acoustic wave pressure sensor are isolated from the external environment; the silicon-based pressure-sensitive film is deposited with a piezoelectric film on one side of the cavity, and a metal interdigital transducer and a reflection grid are deposited on the piezoel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com