Detecting method for residual stress of steel structure

A residual stress, steel structure technology, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of lack of normative regulations, insufficient research, and no obvious improvement of measurement accuracy, to reduce the depth, facilitate operation, Reduce the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

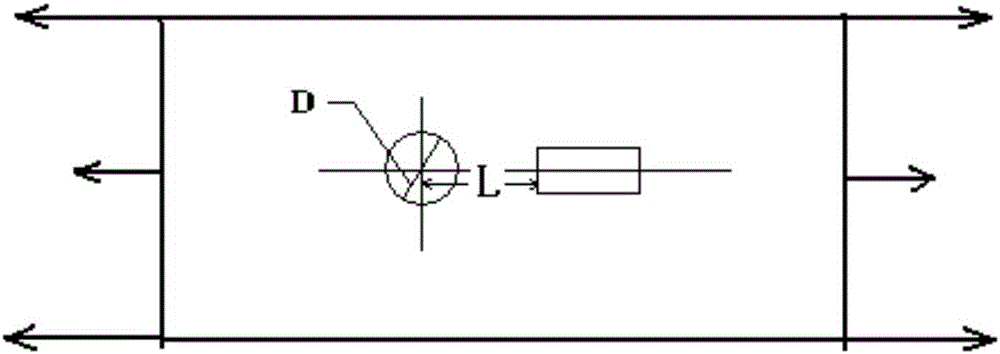

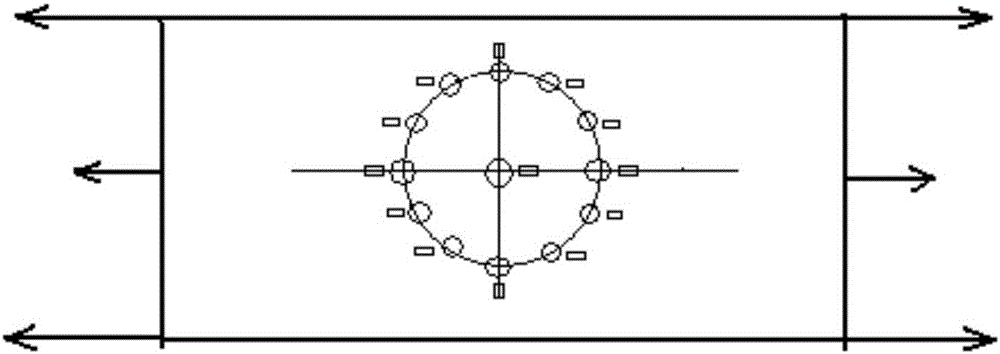

[0036] Embodiment 1: The size of the selected test member is: length A=0.08m, width B=0.05m, thickness 0.08m, hole diameter D=2.5mm, hole depth L=27.5mm, hole inclination angle of 35 degrees, strain gauge The distance from the hole is H=2mm, the modulus of elasticity is E=350GPa, the load is 2MPa and the average distribution force is applied, the number of holes is 13, the value of each hole is measured five times, the average value is taken, and the reverse side is used for simultaneous measurement, specifically as follows figure 2 As shown, the results measured three times were 52.33MPa, 56.25MPa and 53.12MPa respectively, and finally the average value was obtained to obtain 53.90MPa.

Embodiment approach 2

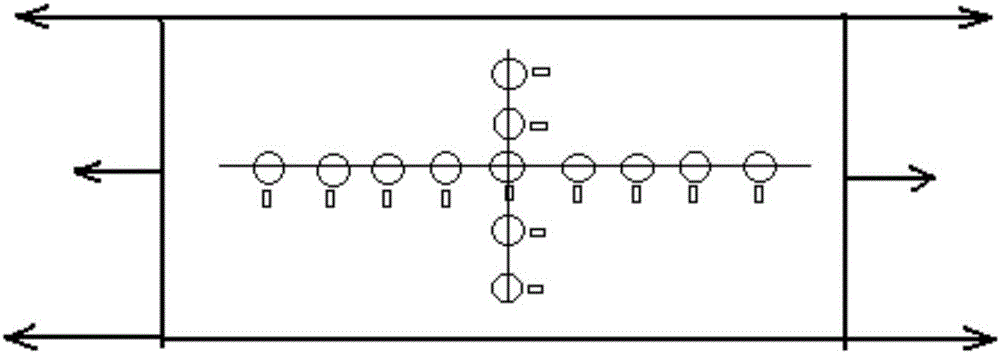

[0037]Embodiment 2: The size of the selected test member is: length A=0.10m, width B=0.04m, thickness 0.08m, hole diameter D=2.0mm, hole depth L=22.0mm, each hole is distributed as a cross, and the distance between the strain gauges Hole distance H = 2mm, elastic modulus E = 350GPa, load 2MPa average distribution force, the number of holes is 13, the value of each hole is measured five times, take the average value, and use the positive and negative sides to measure at the same time, specifically as follows image 3 As shown, the results measured three times are 65.23MPa, 67.25MPa and 66.14MPa respectively, and finally the average value is obtained to get 66.21MPa.

[0038] On the basis of the existing technology, the present invention further optimizes the requirements of specific parameters in the measurement of steel structure residual stress through a large number of experimental studies, by accurately setting the diameter of the borehole, the depth of the borehole, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com