Improved structure of reactor core water compensating box simulator

A technology of a core replenishment tank and a simulated body, which is applied in the fields of reactors, greenhouse gas reduction, nuclear power generation, etc., can solve the problems of increasing the research difficulty of the core replenishment tank, affecting the accuracy of liquid level measurement, and fluid temperature stratification. The temperature measurement arrangement is effective and reasonable, realizes self-calibration, and reduces the processing difficulty and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

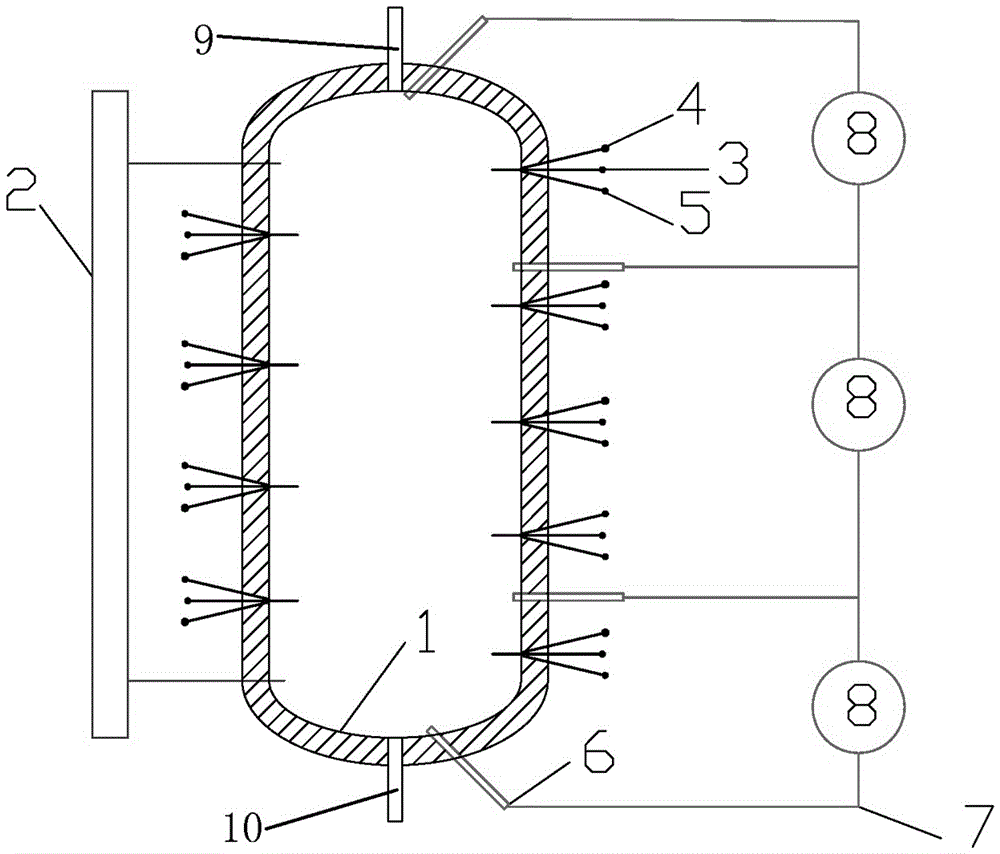

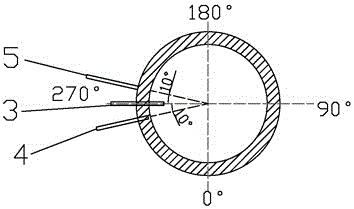

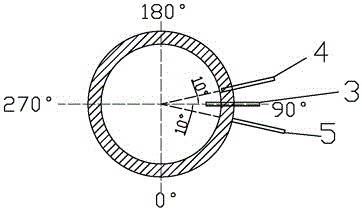

[0024] Such as Figures 1 to 3 As shown, the core make-up water tank simulation body cylinder 1 is composed of an upper spherical head, a middle cylindrical body, and a lower spherical head through welding. A hole is opened at the bottom, and 10 pipes are connected to the outlet of the welding fluid, and a magnetic flap liquid level gauge 2 is installed on the cylinder body 1 of the simulation body of the core water supply tank to measure the liquid level change of the fluid in the cylinder body 1 of the simulation body of the core water supply tank; The magnetic flap liquid level gauge 2 is installed on the cylinder body 1 of the simulation body of the core water supply tank, and is parallel to the axial centerline of the cylinder body 1 of the simulation body of the core water supply tank, and can accurately measure the total liquid level of the simulation body;

[0025] The pressure measuring assembly 6 is installed through the cylinder body 1 of the simulation body of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com