Capacitor element impregnating method

A capacitor and element technology, applied in the field of impregnation of capacitor elements, can solve the problems of non-recycling, waste of resources, inability to be effectively covered by monomers, etc., and achieve the effect of high efficiency and high capacity extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

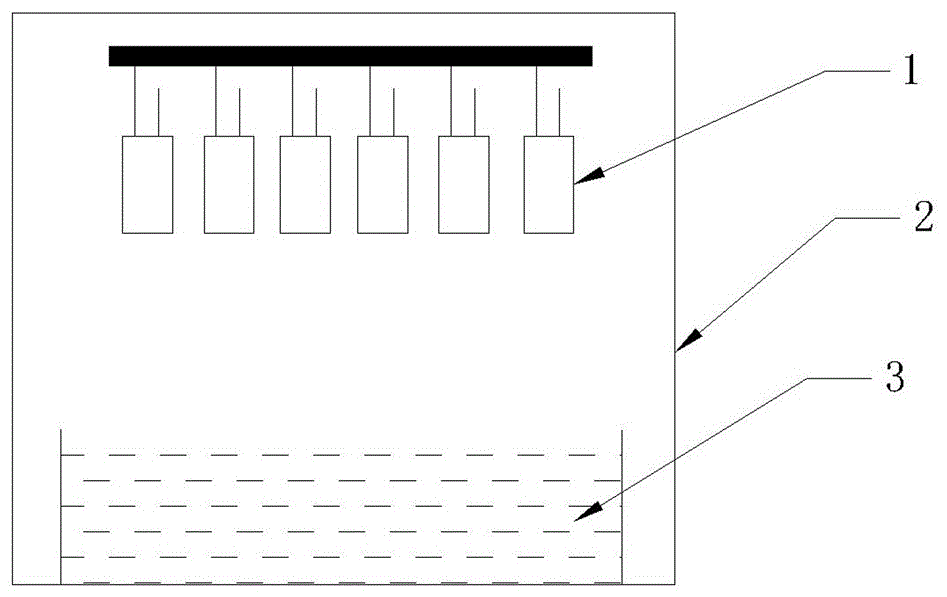

[0020] Such as figure 1 A method for impregnating a capacitor element includes the following steps: 1) placing a conductive polymer monomer 3 in a vacuum furnace 2, and keeping the element 1 above the conductive polymer monomer 3;

[0021] 2) Seal the vacuum furnace 2, and pump the vacuum degree of the vacuum furnace 2 to 1×10 -4 Pa;

[0022] 3) Raise the temperature in the vacuum furnace 2 to 100°C and keep it for 5 minutes; then gradually lower the temperature in the vacuum furnace 2 to 50°C and keep it for 30 minutes;

[0023] 4) The element 1 impregnated with the conductive polymer monomer 3 is taken out of the vacuum furnace, and polymerized to generate PEDT after being impregnated with an oxidant.

[0024] In this embodiment, the conductive polymer monomer is EDOT and its derivatives. The oxidizing agent is aromatic iron sulfonate.

[0025] In this embodiment, step 3) can be repeated 1-3 times.

[0026] The impregnation method of the capacitor element in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com