Sewn ball and making process thereof

A technology of sewing and raw material balls, which is applied in the field of sewing balls and its production technology, can solve the problems of unbalanced ball center of gravity, poor control force, and increased cost, and achieve small flight trajectory deviation, reduce circumference error, The effect of improving rebound ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

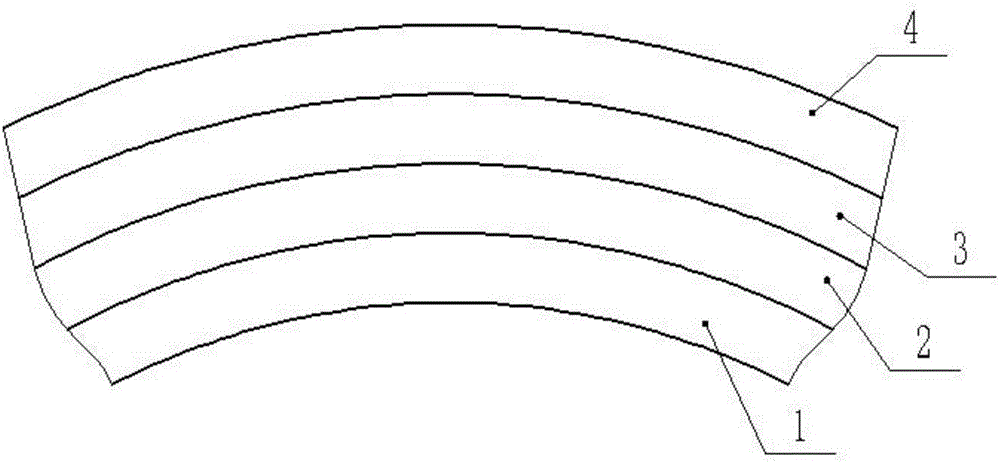

[0042] Such as figure 1 As shown, a sewing ball provided by the present invention includes an inner tube and a shell 4, the inner tube includes an inner tube body 1, a yarn layer 2 and a rubber layer 3, and the yarn layer 2 is attached to the inner tube body 1 The outer surface of the outer surface; the rubber layer 3 is attached to the outer surface of the yarn layer 2, and then vulcanized so that the rubber raw material of the rubber layer 3 penetrates into the yarn gap of the yarn layer 2, The inner tube body 1, the yarn layer 2 and the rubber layer 3 are integrated, and the outer shell 4 wraps and fits the inner tube.

Embodiment 2

[0044] In order to prevent the yarn layer 2 from being too thick and wound onto the inner tube body 1, the surface of the prepared inner tube will be hard, which will affect the bouncing force of the ball. The main body 1 is insufficiently bound, resulting in insufficient strength of the inner tube, poor damage resistance, and not durable. In the present invention, preferably, the thickness of the yarn layer is 0.1-1 mm. The thickness of the yarn layer 2 ensures sufficient binding to the inner tube body 1 and improves the inner tube strength while taking into account the surface hardness of the ball to ensure the bouncing force of the ball.

Embodiment 3

[0046] In order to ensure the balance and flight stability of the ball, when the player hits the ball, the deviation between the actual flight trajectory of the ball and the ideal flight trajectory is small, thereby improving the hitting rate of the ball. The inner tube of the present invention is provided with a balance sheet, and the balance sheet is located on the same axis as the air nozzle and symmetrical to the center of the ball, so that the overall center of gravity of the ball is at the center of the ball.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com