Manipulator suitable for bird egg grabbing

A technology for manipulators and eggs, applied in the field of manipulators, can solve the problem of no special requirements for the positioning accuracy of eggs, and achieve the effects of automatic grasping, small size and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

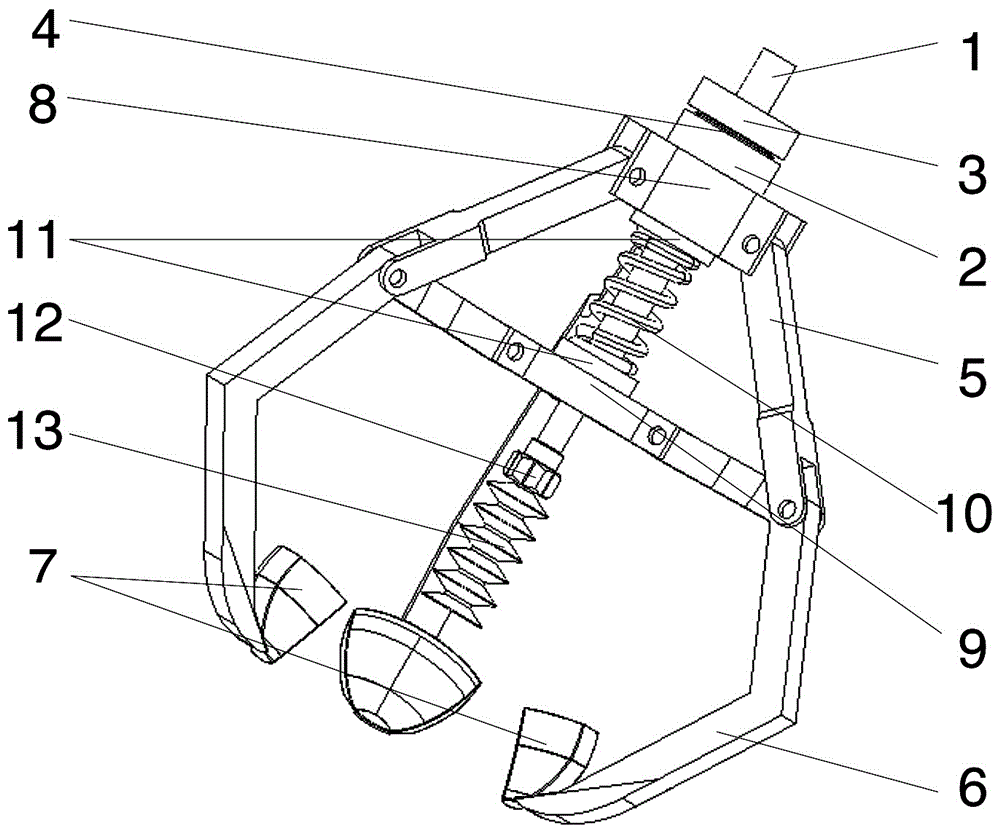

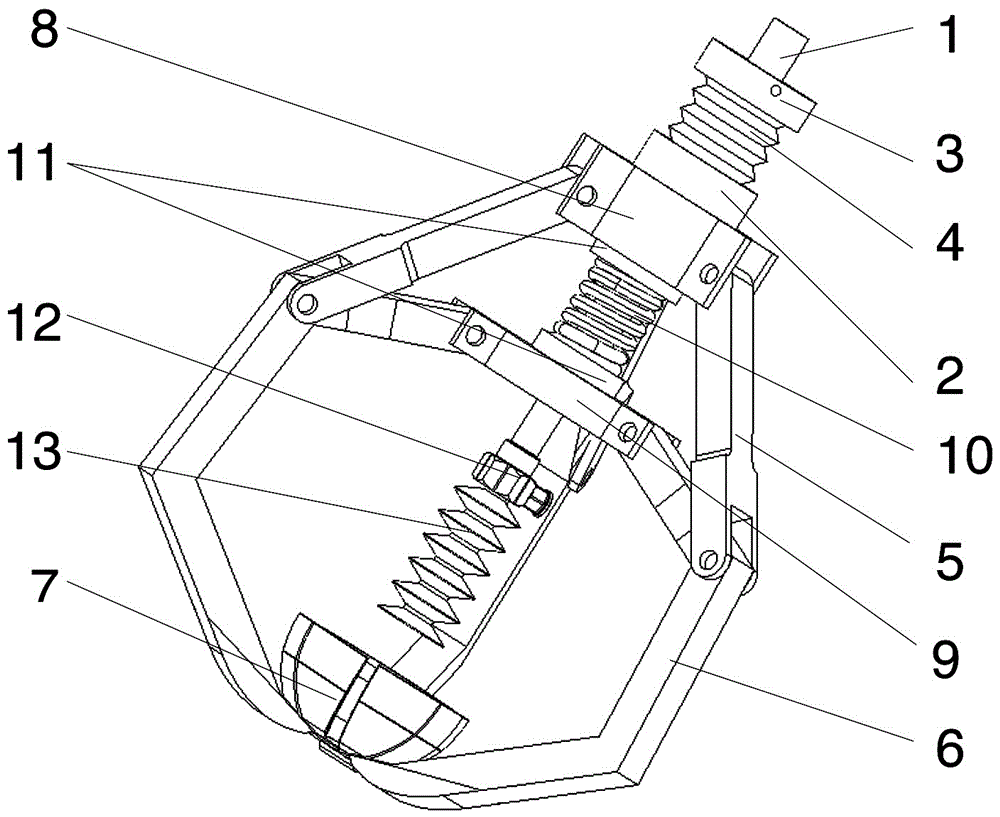

[0032] Such as Figure 1 ~ Figure 4 as shown,

[0033] Pull bar frame 8, gripper frame 9 are installed on the guide rod 1, stage clip 10 is positioned between pull bar frame 8, gripper frame 9.

[0034] A pull bar 5 is movably installed between the pull bar frame 8 and the claw frame 9, and the claw 6 is movably installed on the claw frame 9, and an egg tray 7 is provided at the end of the claw 6.

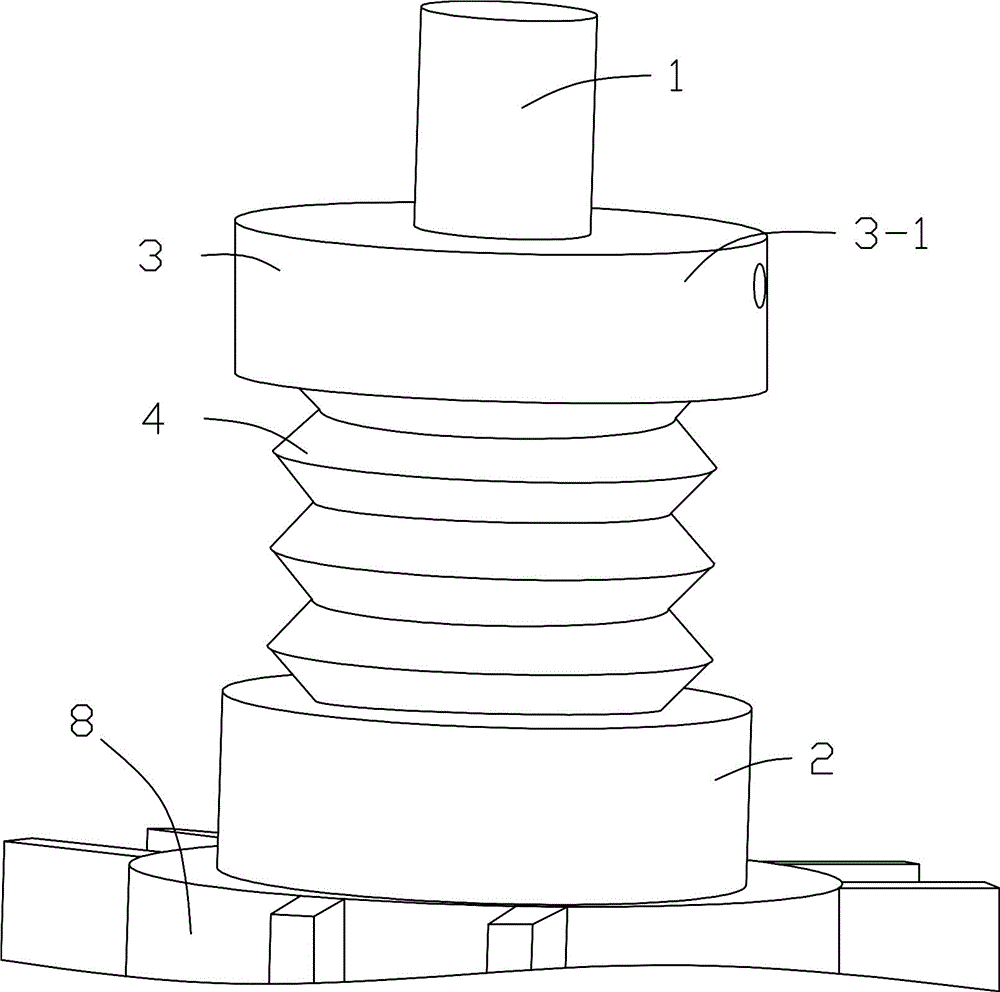

[0035] The air bag seat 3 is connected with the air bag 4 through a sealed gas channel, and the air bag seat 3 has holes inside to allow gas to pass through.

[0036] The radial size of the airbag seat 3 is slightly larger than the diameter of the airbag 4 when it is fully inflated, so as to ensure that the airbag 4 has a suitable movement space in the radial direction.

[0037] The airbag seat 3 is threadedly engaged with the guide rod 1, and the maximum opening angle of the jaws 6 can be controlled by adjusting the position of the airbag seat 3 on the guide rod 1 through thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com