An automatic tube sealing device for eager cutting culture plate

A culture plate and eager-cutting technology, which is applied in the field of automatic tube sealing device for eager-cut culture plates, can solve the problems of microbial contamination of culture plates and influence on culture results, and achieve the effects of reducing costs, labor intensity, and human errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

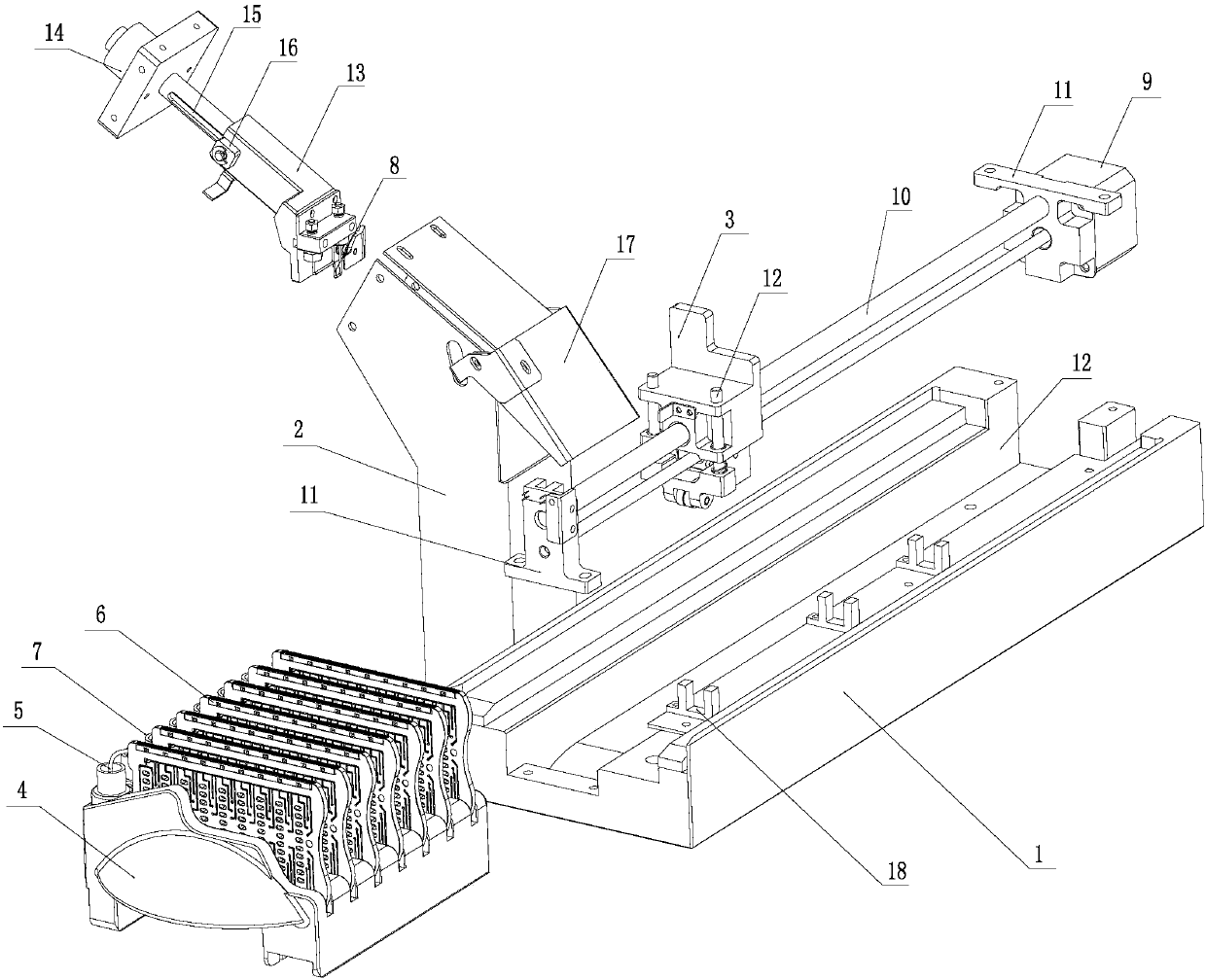

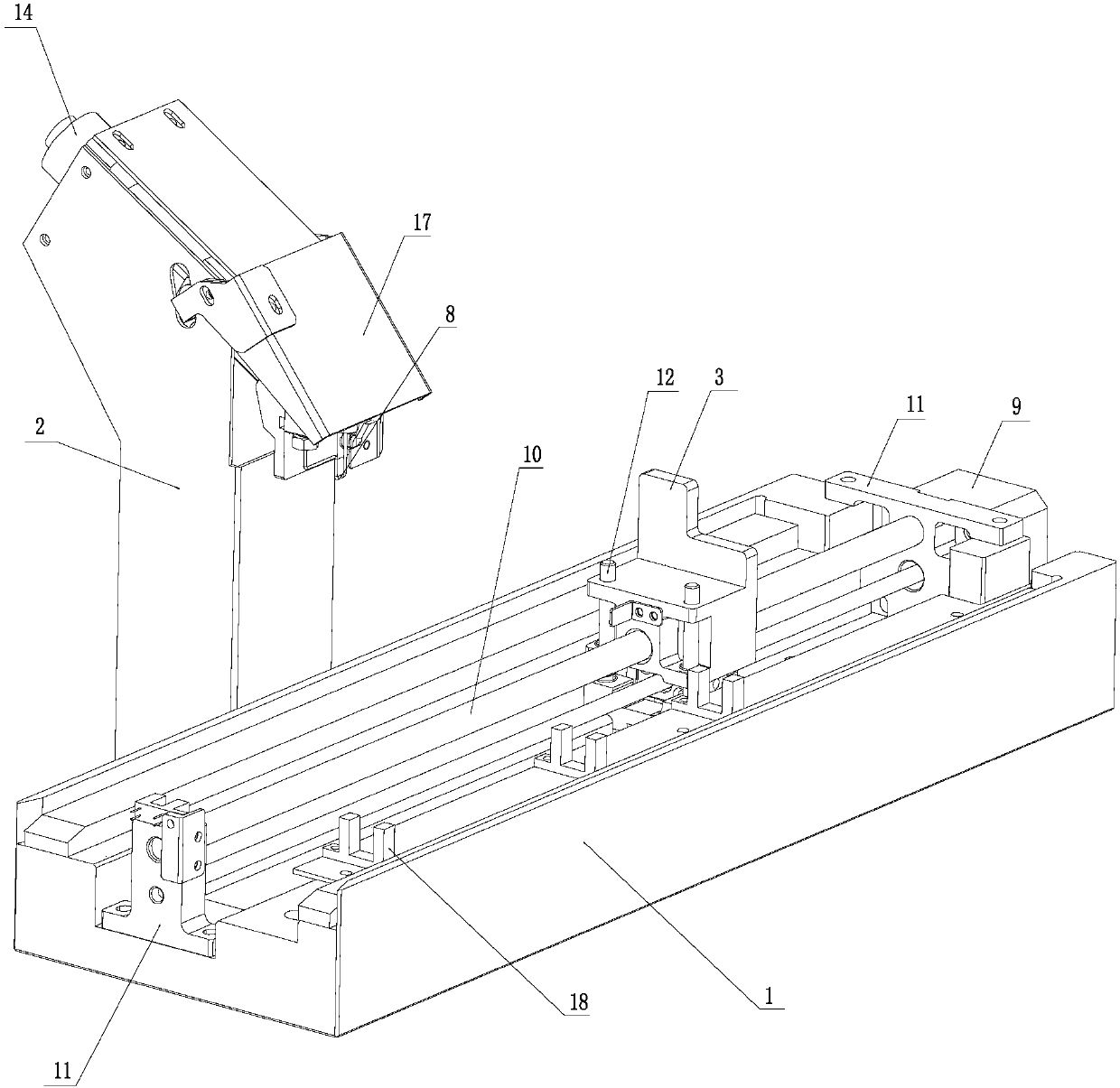

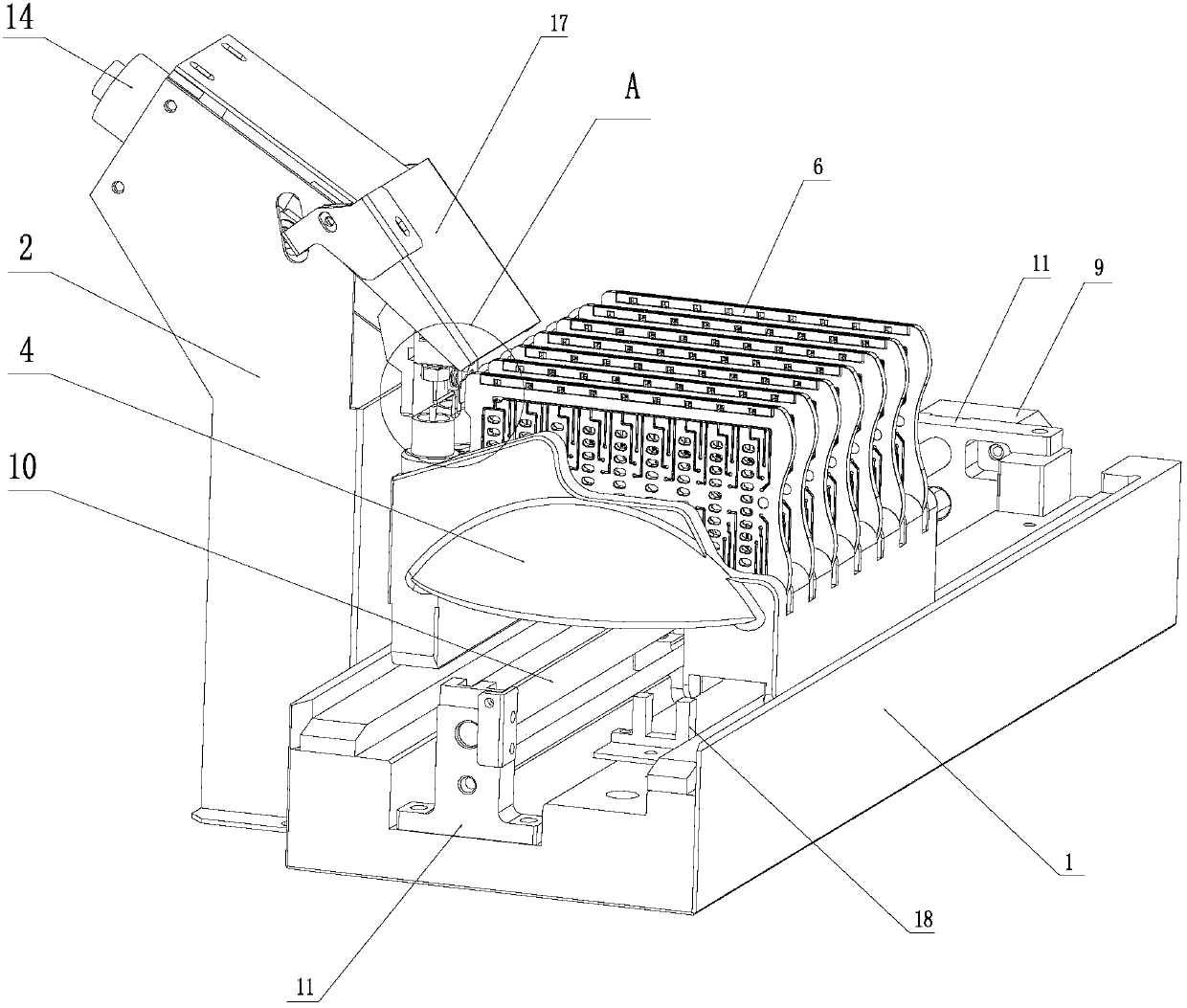

[0019] The present invention will be further described below in conjunction with the accompanying drawings and the preferred embodiments of the present invention:

[0020] refer to figure 1 and figure 2 , an eager type culture plate automatic sealing device, comprising a base 1, the base 1 is provided with a plate frame 4, on the plate frame 4 is movably placed a culture plate 6 and a liquid bottle 7 connected by a rubber tube 5, so A bracket 2 is provided on one side of the base 1 , and a hot-cutting component is connected to the bracket 2 . The hot-cutting component includes an electric heating wire 8 , and the electric heating wire 8 is in contact with the rubber tube 5 during hot-cutting.

[0021] The base 1 is provided with a front and rear moving assembly, the front and rear moving assembly is a tubular linear motor group, and the tubular linear motor group includes a first drive motor 9, and the first drive motor 9 is a linear motor, so The first drive motor 9 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com