Packed bed type cell bioreactor without stirrer and method for cultivating animal cells

A technology of cell biology and packed bed, which is applied in the direction of biochemical equipment and methods, microorganisms, biochemical instruments, etc., can solve the problems of pollution, cell death, high occurrence rate, etc. small force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

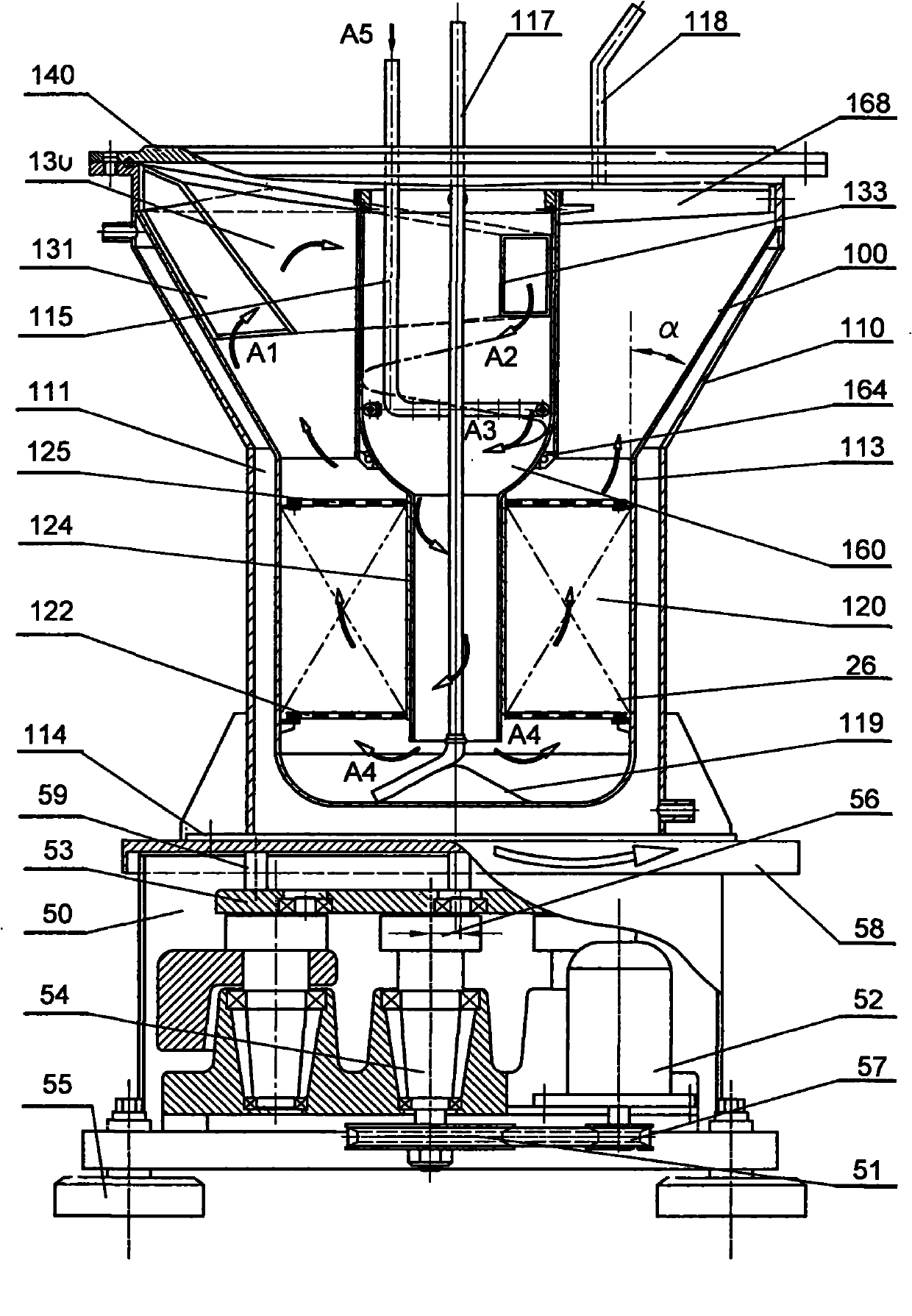

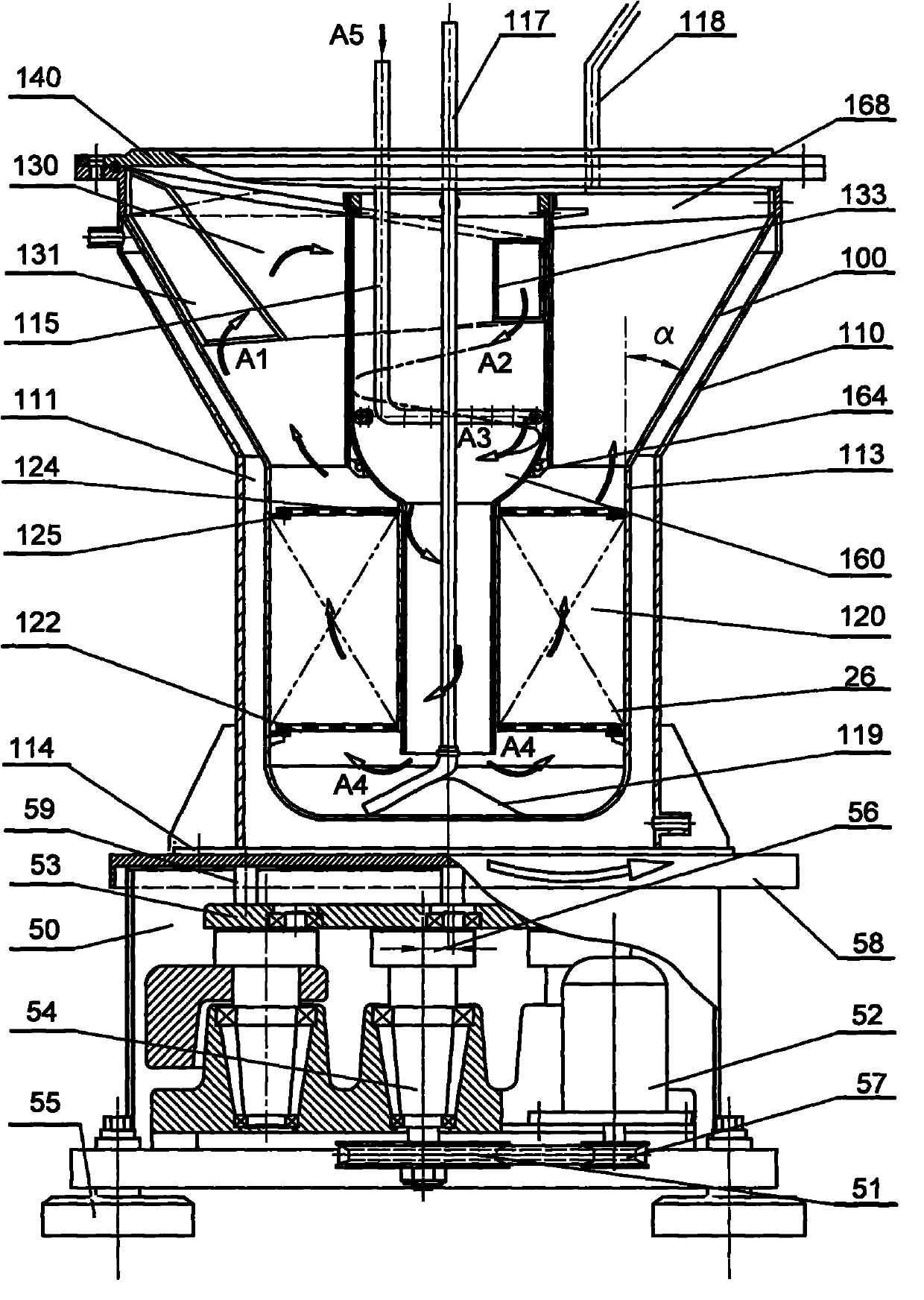

[0021] A packed bed cell bioreactor without stirring device, its composition includes: a reaction tank body 110, the reaction tank body is connected to the shaker 50 through an eccentric shaker plate 58, and the shaker shakes the eccentric shaker plate to make the reaction tank body For eccentric rotation. The upper part of the reaction tank body 110 is in the shape of a truncated cone 100, and the lower part is in the shape of a cylinder 113. The upper part of the truncated cone is equipped with a draft tube 130, and the inlet 131 of the draft tube is close to the reaction tank. The inner wall of the body, the outlet 133 end of the draft tube enters the central funnel 160 along the tangential direction of the central funnel, and the tank body of the reaction tank has a tank with an air inlet, an air outlet, a liquid inlet, and a liquid outlet. Cover 140, the inside of the reaction tank has a packed bed 120.

Embodiment 2

[0023] In the packed bed cell bioreactor without stirring device in Example 1, the packed bed includes an upper orifice plate 125 , a lower orifice plate 122 and an empty casing 124 . The cylindrical 113 inner wall of the reaction tank body 110 is connected with the lower orifice 122 and the empty casing 124, the upper end of the empty casing 124 is connected with the upper orifice 125, the upper orifice 125, the empty casing 124 1. The lower orifice plate 122 constitutes the packed bed 120, and the sheet microcarrier 26 is filled between the lower orifice plate and the upper orifice plate. The packed bed 120 is consistent with the center line of the reaction tank body 110 . The reaction tank has a base 114, the reaction tank 110 is connected to the rocking plate 58 through the base 114, and the reaction tank body 110 and the tank cover 140 are connected by bolts.

[0024] The inner surface of the frustum-shaped cone 100 is connected to the inlet 131 of the draft tube, and th...

Embodiment 3

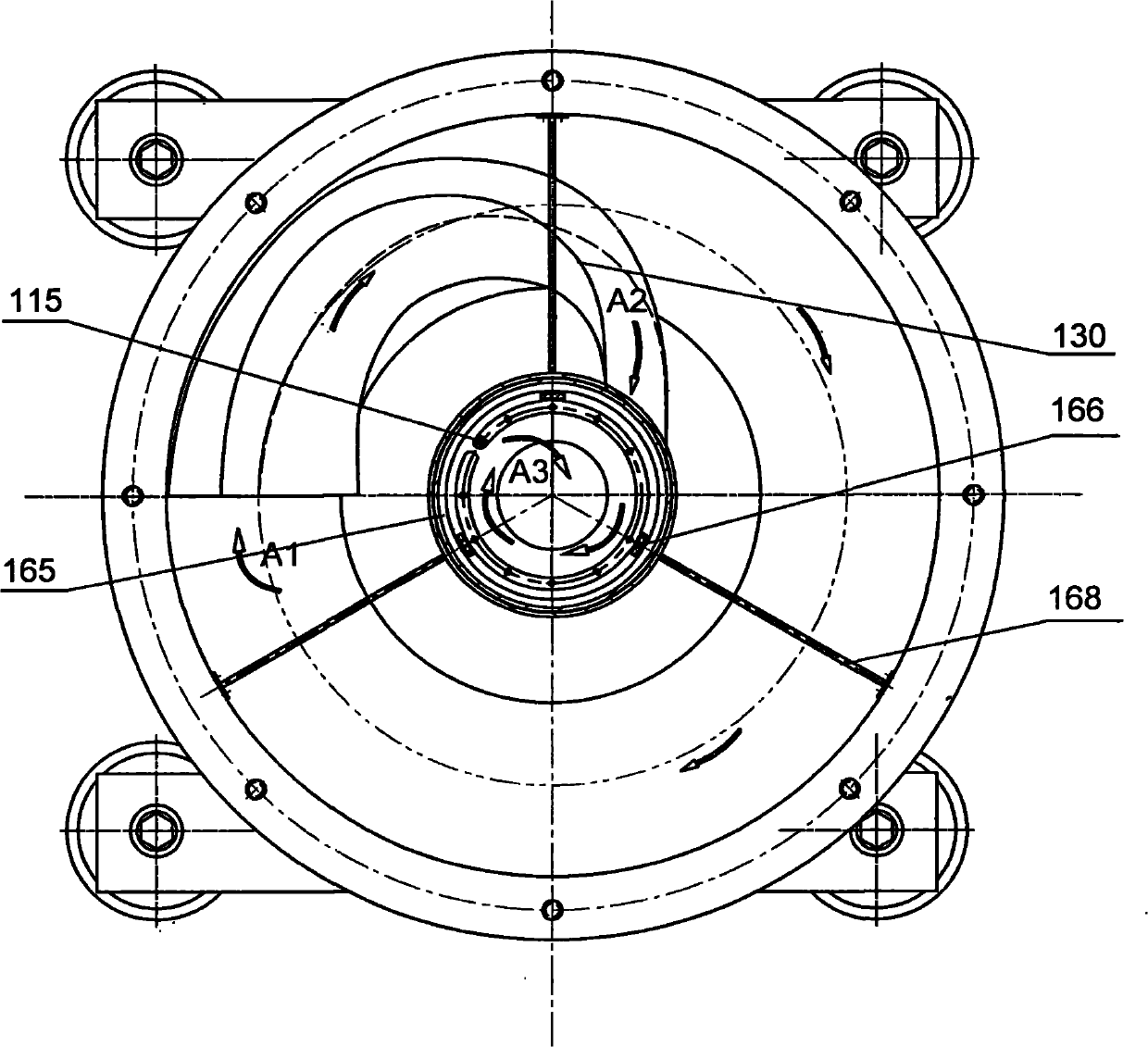

[0026] In the packed bed cell bioreactor without stirring device described in embodiment 1 or 2, the central funnel has an outer jacket 164, and the central funnel is equipped with a pressure ring 165 and a pressure ring top wire 166 in the central funnel outer jacket 164 Compressed, the center funnel is set on the center line of the tank body, and the center funnel coat passes through figure 2 3 central funnel coat supports 168 in the fixed.

[0027] In the packed bed cell bioreactor without stirring device, the semi-cone angle α of the frustum-shaped conical surface of the upper part of the reaction tank is 25° to 55°, such as 30° or 35°, 40°, 45° or 50°, can be determined through experiments according to the concentration of the required nutrient solution and the speed of the required circulation, generally between 30-42° is better, and the reaction tank has an insulating water jacket 111 outside .

[0028] In the packed bed cell bioreactor without stirring device, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com