Highly-precise linear intelligent control filling mechanism and linear filling method thereof

An intelligent control, high-precision technology, applied in packaging automatic control, packaging, liquid bottling, etc., can solve the problems of inability to accurately control the depth of the charging gun, inability to effectively control the filling process, affecting the filling accuracy, etc. The effect of less, less attached material and faster filling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

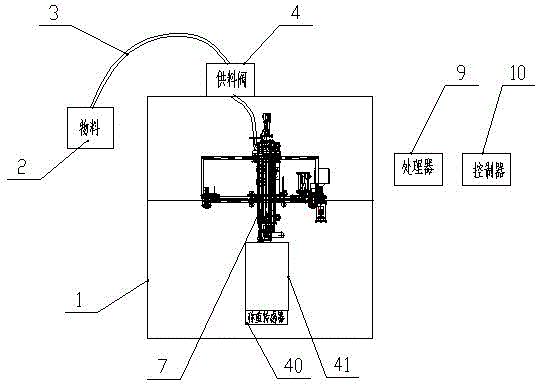

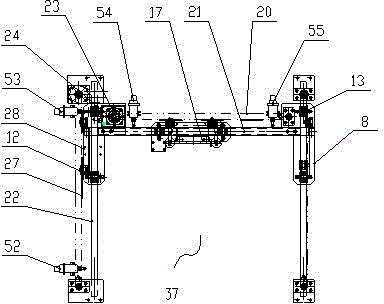

[0029] Such as figure 1 It is a structural schematic diagram of the filling mechanism of the present invention. A linear intelligent control high-precision filling mechanism includes a filling mechanism, a charging gun, a sliding mechanism, a processor and a controller. The sliding mechanism 37 used to move the filling mechanism 7 from a predetermined initial position to directly above the opening of the material container 41, the filling mechanism 7 is arranged on the sliding mechanism 37, and the sliding mechanism 37 is arranged on the body 1 Above; the filling mechanism 7 and the sliding mechanism 37 are connected to the processor 9 and the controller 10 respectively.

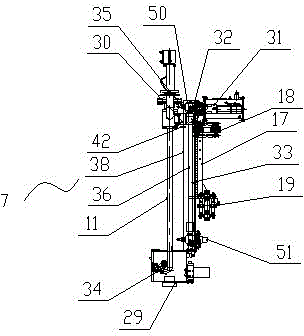

[0030] Such as figure 2 It is a structural schematic diagram of the filling mechanism of the present invention. The vertical servo motor 31 is installed on the trolley 17, and the front end of the servo motor 31 is equipped with a vertical synchronous pulley 32 and a vertical synchronous belt 33. Guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com