Green synthesis method for tributyrin for high-content feed

A tributyrin and green synthesis technology, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of high price and uneconomical storage of butyryl chloride, and achieve favorable storage , easily decomposed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

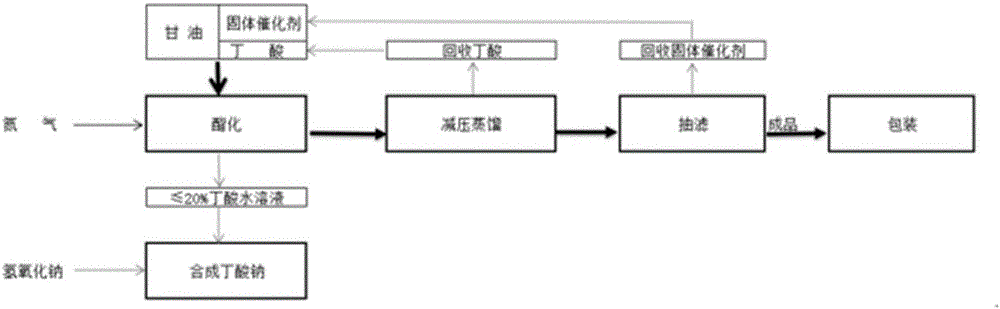

Method used

Image

Examples

Embodiment 1

[0033] (1) Add 28g (0.3mol) of glycerin and 400g (1.5mol) of butyric acid with a content of 99.5% to a 1000ml four-necked reaction bottle (with electric stirring, thorn-type rectification column and a nitrogen tube inserted into the bottom of the bottle), and then add SO 4 2- / ZrO 2 -TiO 2 Solid superacid catalyst 0.6g, start stirring.

[0034] (2) The oil bath is heated to 100°C, and an appropriate flow rate of nitrogen gas is introduced from the bottom. The water containing butyric acid was distilled into the receiving bottle through the thorn rectification tube and the condenser, and the temperature was slowly raised to 148°C as the water continued to evaporate until there was no distillate. 19 ml of water containing 18.3% butyric acid was distilled off.

[0035] (3) After cooling down to 80°C, continue heating, turn on a small amount of nitrogen and small bubbles will emerge, distill the remaining excess butyric acid under reduced pressure, and collect butyric acid wi...

Embodiment 2

[0038] Process is with embodiment 1, and butyric acid uses the butyric acid 311g that embodiment 1 reclaims and the neobutyric acid of 100g99.5%, and solid superacid catalyst uses the recovery catalyst of embodiment 1. The product was light yellow and transparent, with a yield of 96.4% relative to glycerin, a tributyrin content of 95.6%, and a moisture content of 68ppm.

Embodiment 3

[0040] Process is with embodiment 1, uses SO 4 2- / Fe 2 o 3 -TiO 2 Solid superacid catalyst instead. Obtain light yellow transparent product, relative yield of glycerin is 96.4%, tributyrin content 95.8%, moisture content 72ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com