A kind of preparation method of trifluoroethylamine hydrochloride

A technology of trifluoroethylamine hydrochloride and trifluoroethylamine, which is applied in the field of preparation of trifluoroethylamine hydrochloride, can solve the problem that the solvent ether is flammable, the neutralizing agent hydrogen chloride gas is difficult to obtain and use, and it is not easy to industrialize Application and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

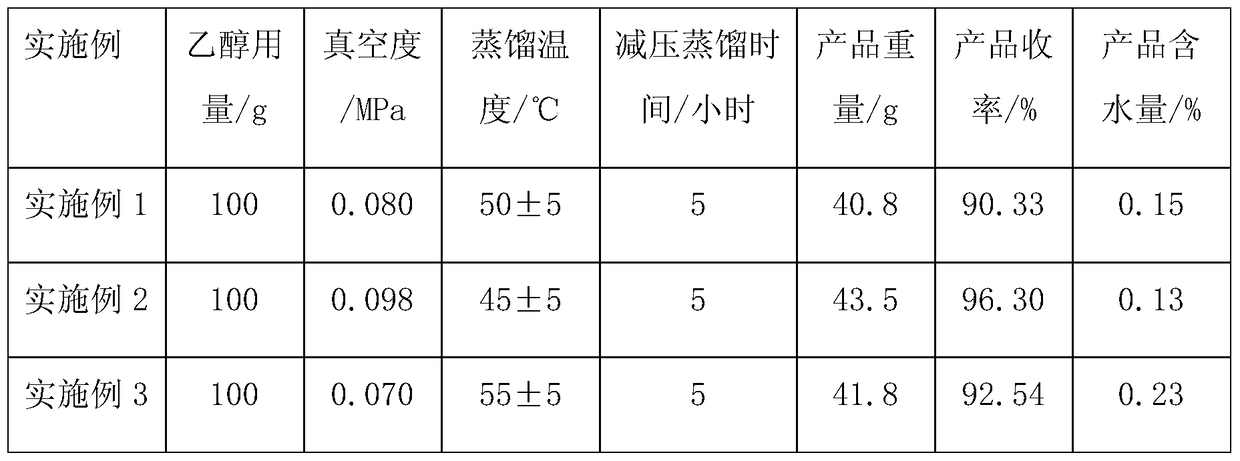

Embodiment 1

[0015] Add 100g of ethanol and 33g of trifluoroethylamine into the three-necked flask, slowly add 35g of saturated hydrochloric acid solution dropwise when the temperature is lower than 25°C, and keep the temperature for one hour for reaction after the dropwise addition is completed. The reaction solution after the reaction was subjected to vacuum distillation and desolventization operation, the vacuum degree of the control system was 0.080MPa, and the temperature was 50±5°C. After 5 hours of vacuum distillation and desolventization operation, the water and ethanol were completely removed to obtain three Fluoroethylamine hydrochloride 40.8g, product yield is 90.33%. The obtained trifluoroethylamine hydrochloride is a white powdery crystalline solid with a water content of 0.15% (the water content of the product is measured with a Karl Fischer moisture meter, the same below).

Embodiment 2

[0017] Add 100g of ethanol and 33g of trifluoroethylamine into the three-neck flask, slowly add 35g of saturated hydrochloric acid solution dropwise when the temperature is lower than 25°C, and then raise the temperature to 50°C and keep it warm for one hour. After the reaction, the vacuum degree of the reaction solution in the system is 0.098MPa, the temperature is controlled at 45±5°C, and the water and ethanol are removed after 5 hours of vacuum distillation and desolvation operation to obtain trifluoroethylamine hydrochloride 43.5 g, the product yield is 96.30%. The obtained trifluoroethylamine hydrochloride is a white powdery crystalline solid with a water content of 0.13%.

Embodiment 3

[0019] Add 100g of ethanol and 33g of trifluoroethylamine into the three-neck flask, slowly add 35g of saturated hydrochloric acid solution dropwise when the temperature is lower than 25°C, and then raise the temperature to 50°C and keep it warm for one hour. After the reaction, the vacuum of the reaction solution in the system is 0.070MPa, the temperature is controlled at 55±5°C, and the water and ethanol are removed after 5 hours of vacuum distillation and desolventization to obtain trifluoroethylamine hydrochloride 41.8g, the product yield is 92.54%. The obtained trifluoroethylamine hydrochloride is a white powdery crystalline solid with a water content of 0.23%.

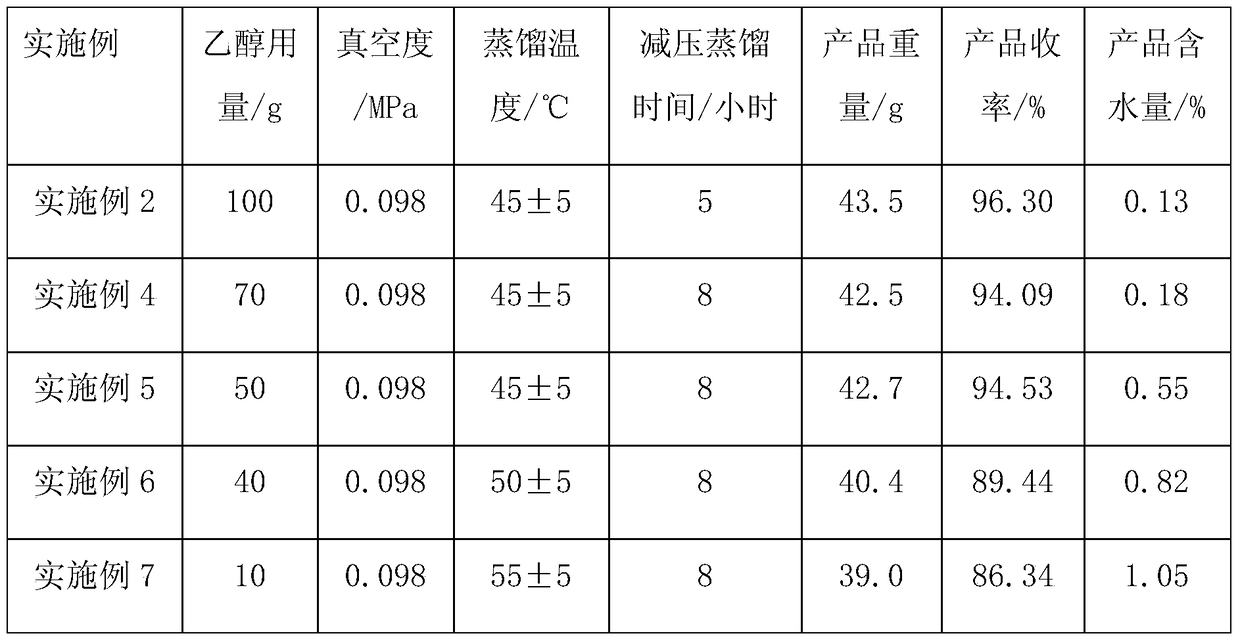

[0020] Table 1

[0021]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com