A kind of nano-bainite material containing rare earth la element, steel rail and preparation method thereof

A technology of nano-bainite and elements, which is applied in the direction of steel rails, rails, manufacturing tools, etc., can solve the difficulty of matching the strength, toughness and extensibility of bainite steel rails at the same time, limit the popularization and application of bainite steel rails, and have no correlation with rare earth Problems such as patents and reports, to achieve economical and recyclable, easy to mass production, save the effect of heat treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

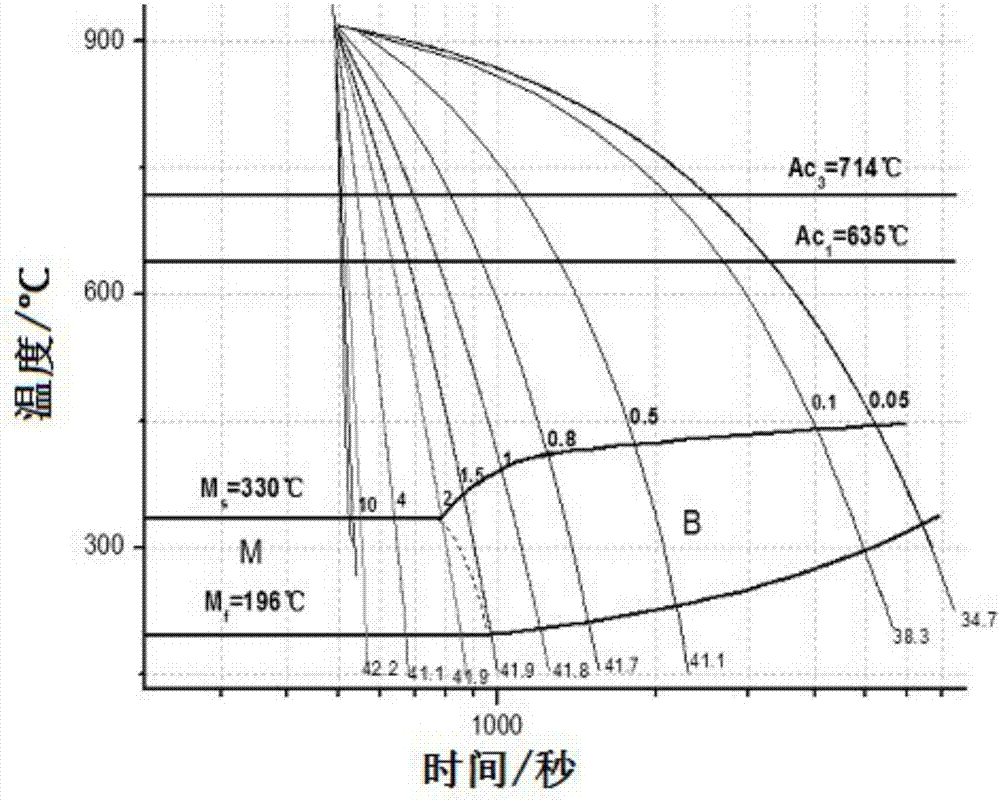

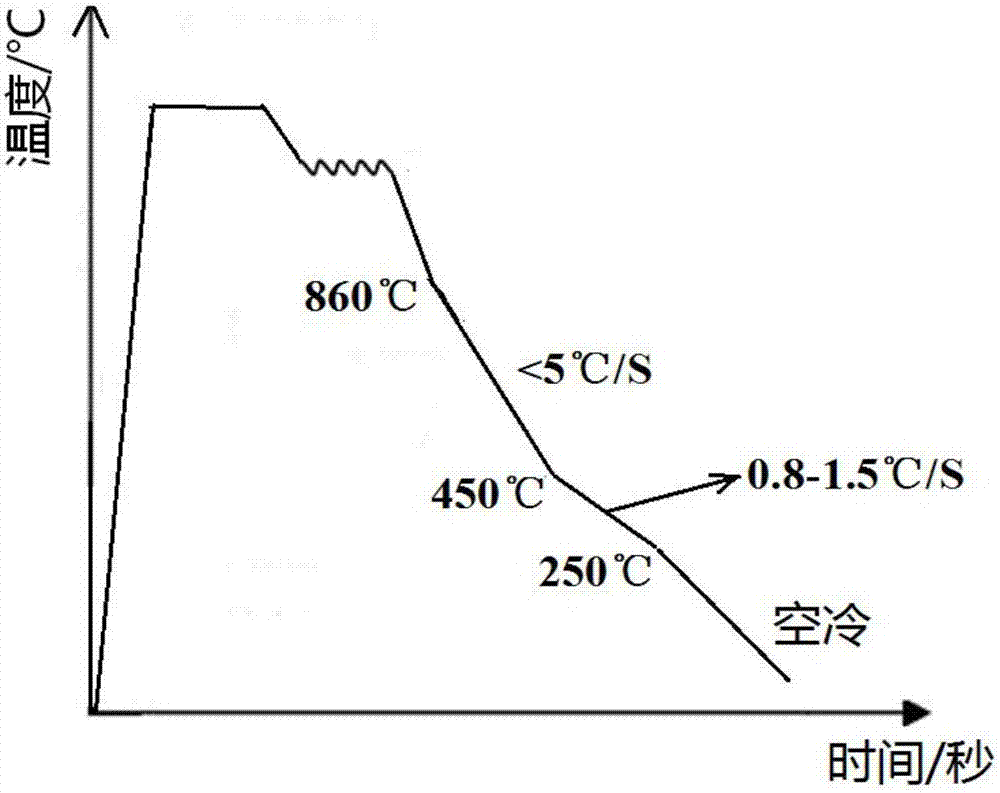

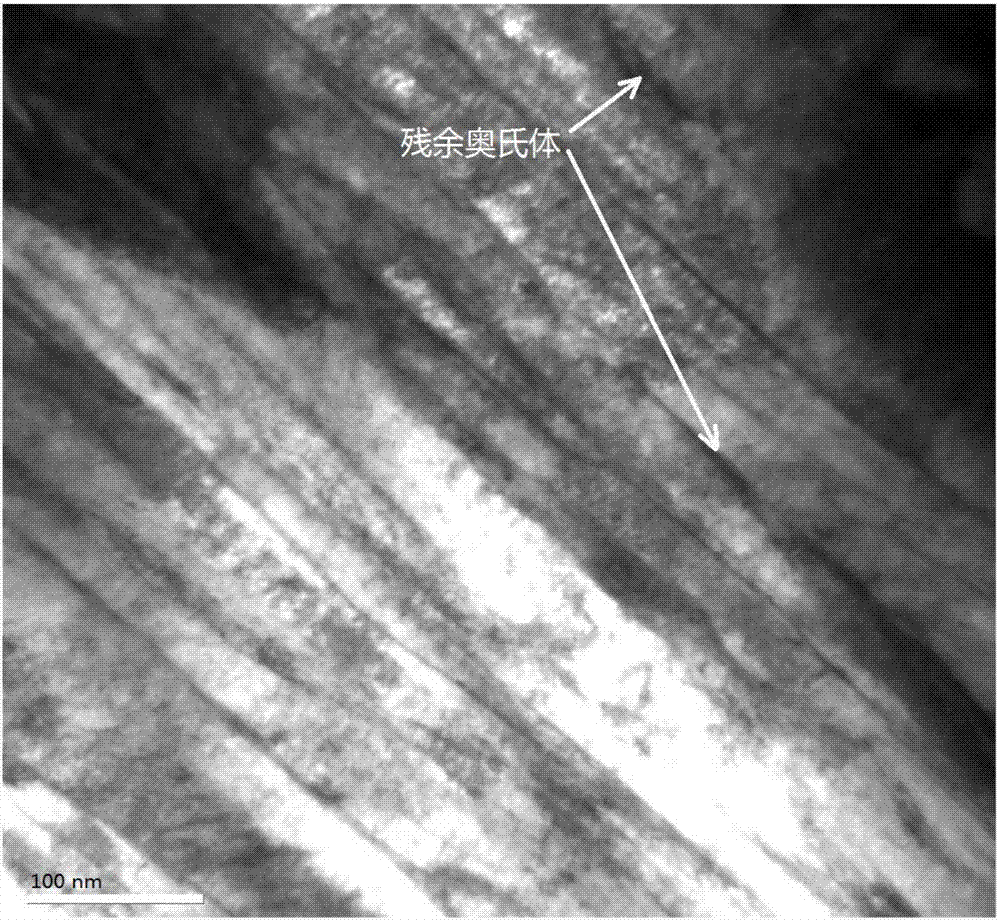

[0042] In the preparation method of the nano-bainite material containing the rare earth La element of the present invention, it includes: a deoxidation and desulfurization step, deoxidizing and desulfurizing the matrix of the nano-bainite material, so as to obtain a pure material structure; an element addition step, In the obtained pure material structure, the added elements and content percentages by weight are: carbon C: 0.18%-0.30%, manganese Mn: 1.4%-1.8%, silicon Si: 0.8%-1.0%, chromium Cr≤1.0%, molybdenum Mo: 0.25-0.32%, lanthanum La: 0.0050%-0.015%, the rest is iron Fe and impurities, the total amount of manganese, silicon, chromium and molybdenum satisfies the relationship: 3.0%≤Mn+Si+Cr +Mo≤3.82%; and a refining and vacuum degassing step, performing vacuum degassing treatment on the material structure obtained after adding elements.

[0043] In the refining and vacuum degassing steps, enter the LF furnace (LADLE FURNACE, ladle refining furnace) for refining after addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com