Titanium nitride deposition system

A deposition system, titanium nitride technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of waste machine capacity, long preventive maintenance time, etc., to reduce the required time, The effect of improving machine utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

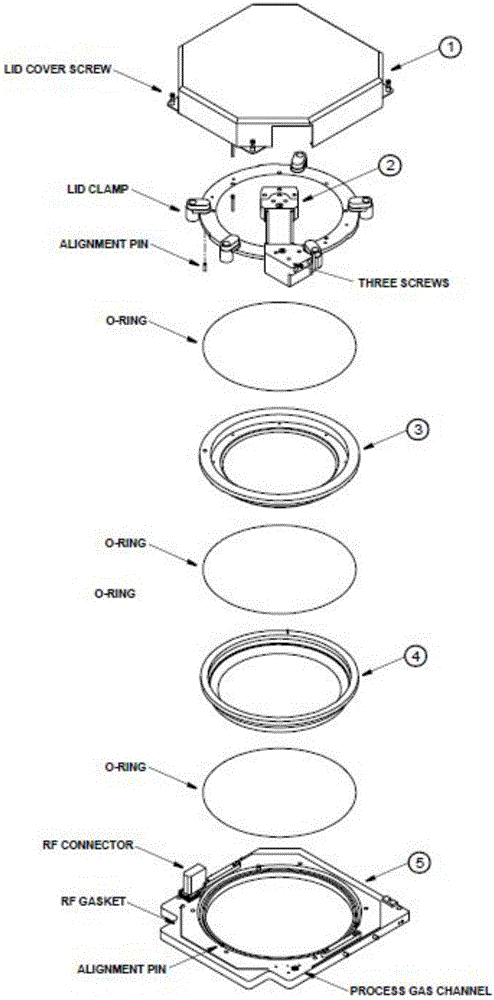

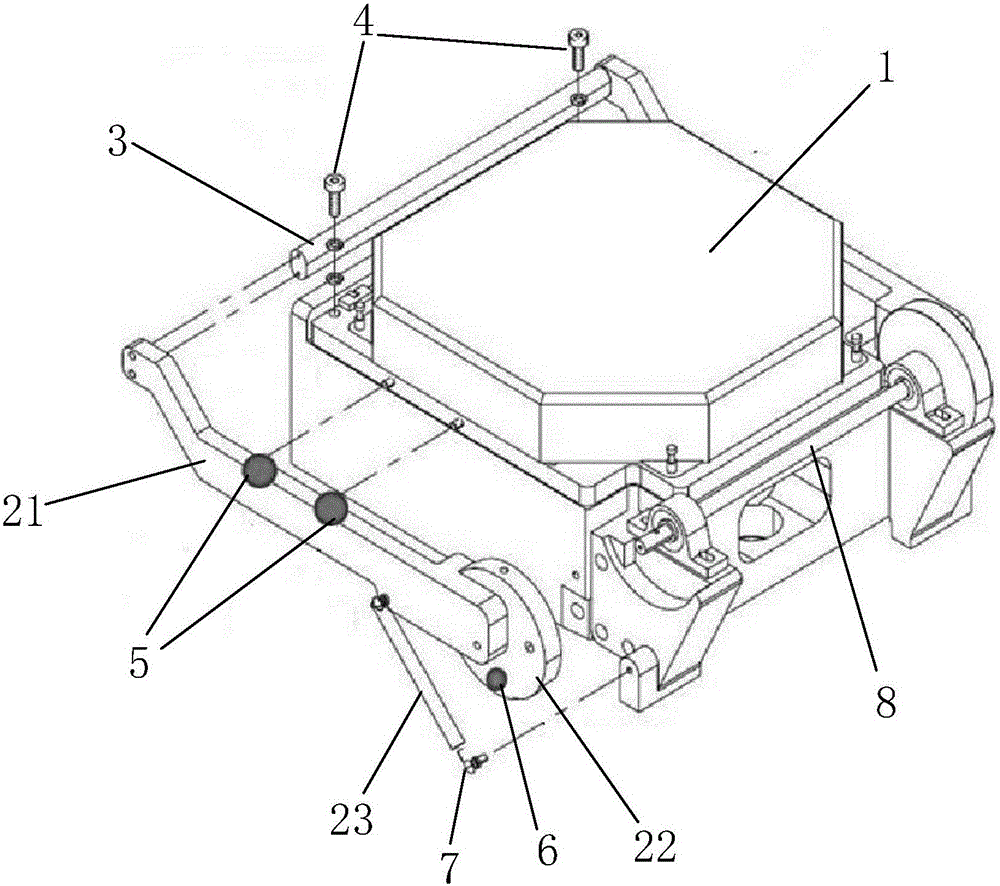

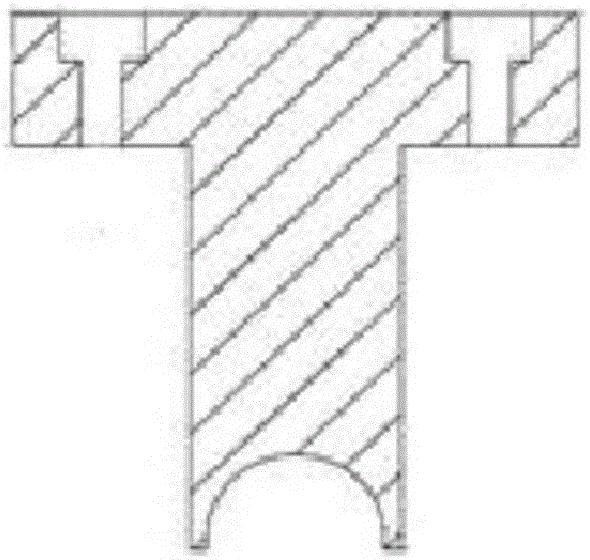

[0018] The following will combine Figure 2 to Figure 4 The titanium nitride deposition system provided by the present invention is described in detail, which is an optional embodiment of the present invention. It can be considered that those skilled in the art can modify and modify it within the scope of not changing the spirit and content of the present invention. polish.

[0019] Please refer to figure 2 , the present invention provides a titanium nitride deposition system, including a chamber assembly 1 and a carrying arm 2, and the chamber assembly 1 is detachably mounted on the carrying arm 2.

[0020] The present invention enables detachable installation between the carrying arm 2 and the chamber assembly 1, so that during maintenance, the entire chamber assembly (ChamberLid) can be dismantled as a whole, and the assembly time and the cleaning time of the gas box (GasBox) etc. Putting it out of the preventive maintenance process, thereby reducing the time required fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com