Unequal-length-leg offshore wind power jacket foundation and construction method thereof

A technology of offshore wind power and construction methods, which is applied in infrastructure engineering, construction, etc., can solve the problems of increased construction period and cost, potential safety hazards of jacket foundation, and difficulty of underwater pile cutting, etc., so as to shorten the construction period and facilitate Construction, the effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

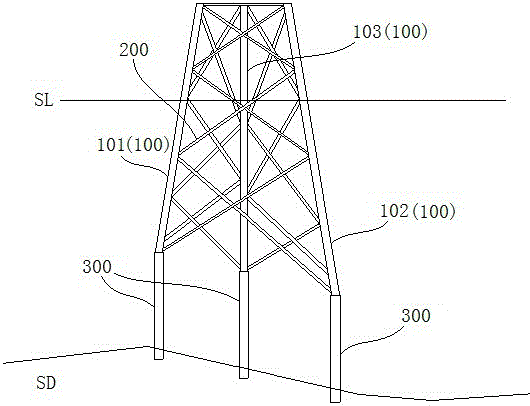

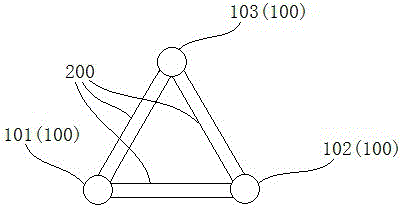

[0024] Embodiment one: Such as Figure 1~2 As shown, the jacket foundation includes three main conduit legs 101, 102, 103 of different lengths, the three main conduit legs 101, 102, 103 are arranged in a triangle, and the main conduit legs 101, 102, 103 are connected to The angle between the horizontal plane is smaller than the angle between the side of the jacket foundation and the horizontal plane, and the diagonal brace 200 is an X-shaped diagonal brace.

Embodiment 2

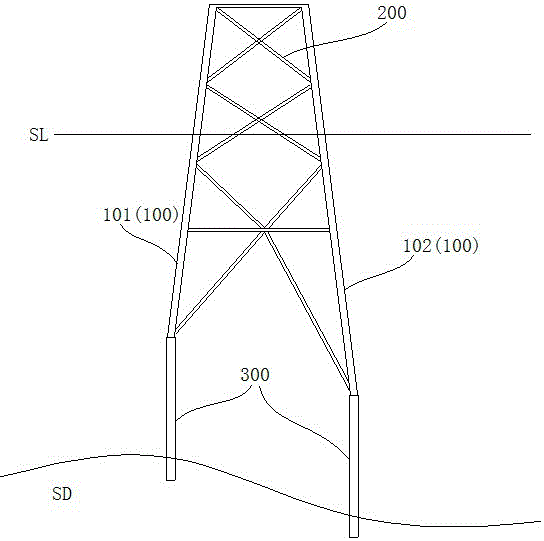

[0025] Embodiment two: Such as Figure 3~4 As shown, the jacket foundation includes four main conduit legs 101, 102, 103, 104 of different lengths, the four main conduit legs 101, 102, 103, 104 are distributed in a quadrilateral, the main conduit legs 101, The angle between 102, 103, 104 and the horizontal plane is smaller than the angle between the side of the jacket foundation and the horizontal plane, and the diagonal brace 200 is a combination of X-shaped diagonal brace and K-shaped diagonal brace.

[0026] The main conduit legs of different lengths are set for the foundation of the offshore wind power jacket, instead of directly using the jacket with equal-length legs to support on the piles in the past, the original jacket is composed of two parts with unequal-length legs and corresponding diagonal braces. In actual engineering application, if encountering complex seabed geological conditions and different elevations of the top of the driven pile, the unequal long legs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com