Breathing valve, fuel tank cap and fuel tank

A technology of breathing valve and fuel tank cover, applied in the field of breathing valve, can solve the problems of polluted air and environment, polluted air, unsatisfactory results, etc., to prevent rupture and damage, and ensure the effect of normal oil supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

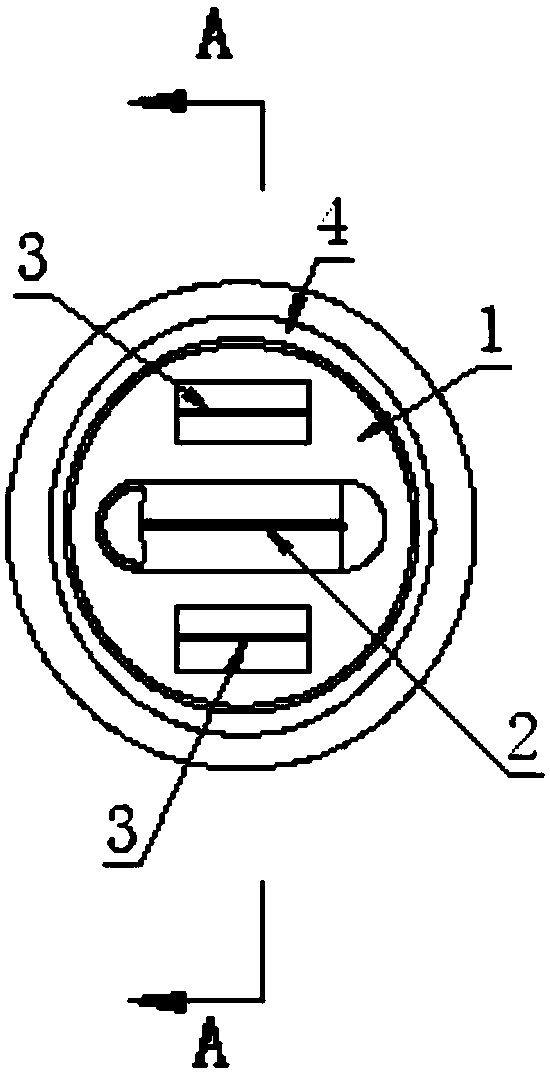

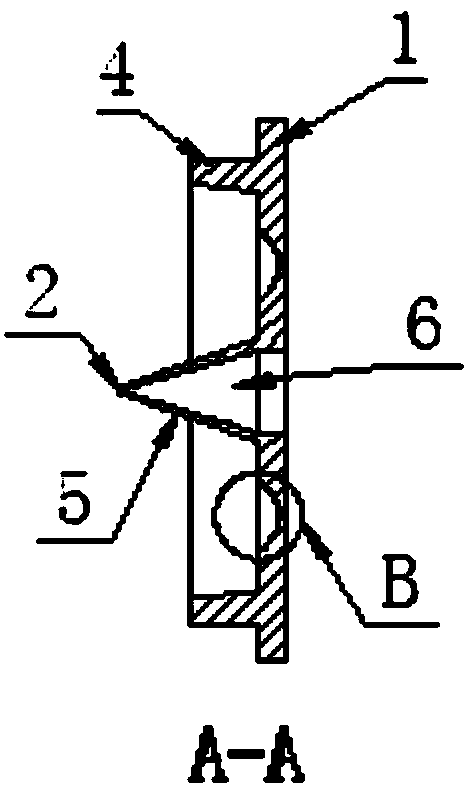

[0045] Such as Figure 1 to Figure 5 As shown, a breathing valve for a fuel tank cap includes a valve body 1 made of elastic material. Starting from 4, the elastic material mentioned here generally refers to rubber material.

[0046] A protruding part 5 for air intake is arranged on one side of the valve body 1, and one side here refers to the side facing the fuel tank after the breather valve is assembled.

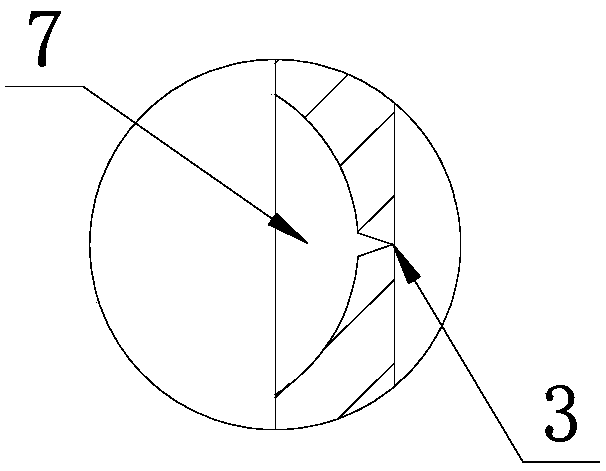

[0047] The protruding part 5 is wedge-shaped, and the protruding part 5 is integrated with the valve body 1 . The protruding part 5 has a cavity 6, and the valve body 1 is provided with a through hole that runs through both ends of the valve body, and the through hole communicates the cavity 6 with the outside atmosphere; When the pressure on one side of the protruding part 5 is lower than the pressure on the other side of the valve body 1, the slit will open; otherwise, the side wall of the wedge-shaped slit 2 can be squeezed and deformed and bonded under the action of...

Embodiment 2

[0051] Such as Figure 6 to Figure 8 As shown, the structure and principle of the breathing valve of Embodiment 1 are the same, the difference lies in the position of the assembly protrusion 4 . In actual use, the position of the assembly protrusion 4 can be flexibly arranged and set according to requirements.

[0052]The fuel tank cap installed with the above-mentioned breather valve can ensure the airtightness of the fuel tank when it is installed on the fuel tank for use, and when the internal and external air pressure of the fuel tank is balanced, the gas volatilized by the fuel in the fuel tank will not be discharged into the atmosphere to pollute the air. When the engine vibrates greatly or works on bumpy road conditions, when the fuel tank is tilted or even inverted, the notch 2 and the slit 3 are all closed to prevent oil leakage. Even if the fuel tank is tilted or turned upside down for a long time, the air pressure in the fuel tank will increase and the cutting seam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com