Dimmable LED light source

A technology of LED light source and LED chip, which is applied in the field of LED light source, can solve the problems such as unsatisfactory dimming and color adjustment, and achieve the effect of avoiding heat loss, simple realization and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

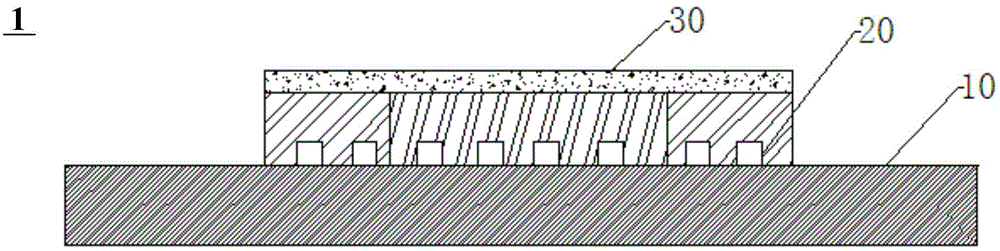

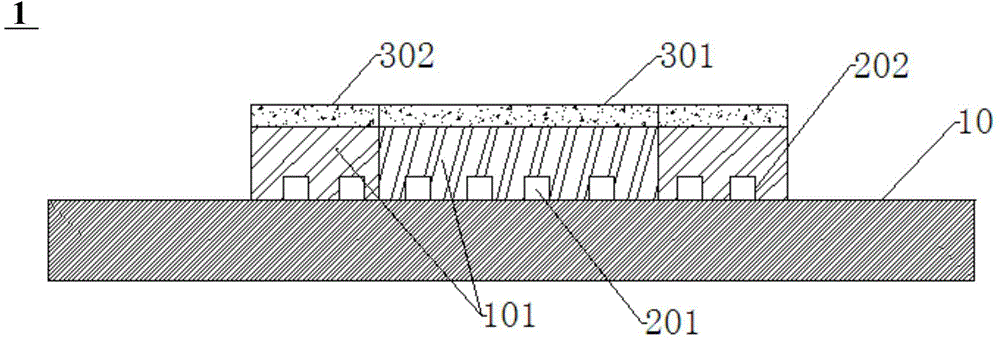

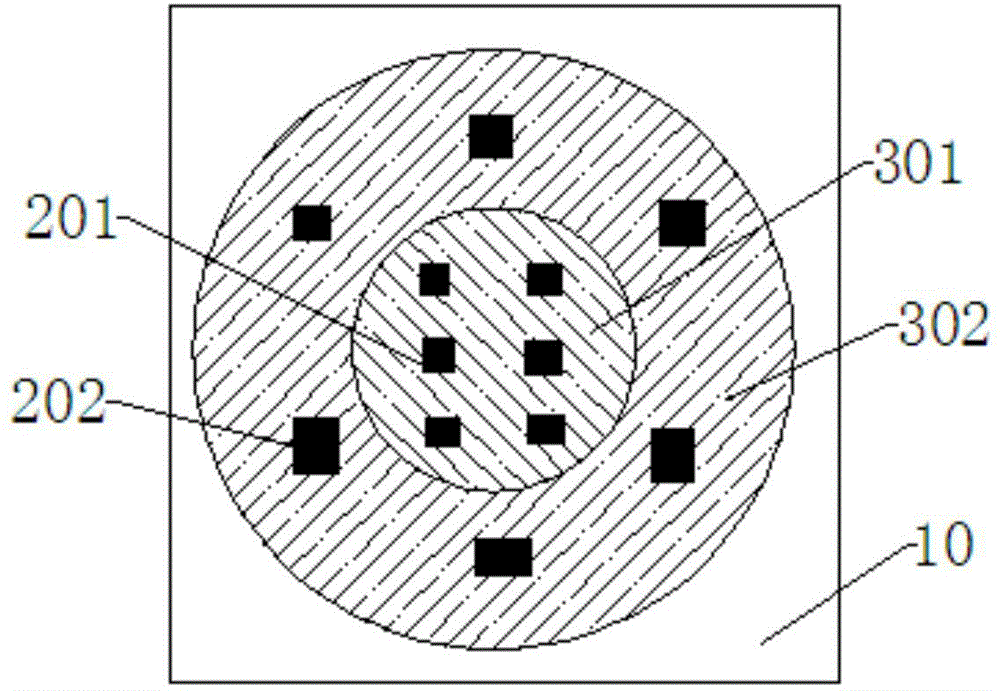

[0063] figure 2 It is a structural schematic diagram of Embodiment 1 of the present invention; image 3 It is a top view of Embodiment 1 of the present invention. figure 2 and image 3 A preferred dimmable LED light source 1 of the present invention is shown, and a first LED chip group 201 and a second LED chip group 202 are arranged on a substrate 10 . Wherein, the LED chip is preferably a blue LED chip. And the first LED chip group 201 and the second LED chip group 202 are arranged on the substrate 10 through COB packaging. The first LED chip group 201 is disposed on the central area of the substrate 10 , and the second LED chip group 202 is disposed around the first LED chip group 201 . Preferably, the annular light emitting area formed by the second LED chip group 202 surrounds the solid circular light emitting area formed by the first LED chip group 201 in a concentric manner. see image 3 , the ring-shaped light emitting area corresponds to the first color area...

Embodiment 2

[0073] Such as Figure 4 As shown, the main difference between this embodiment and embodiment 1 is that the phosphor film 30 is divided into a first color region 301 and a second color region 302 . The first color region 301 includes two parts distributed on the phosphor film 30 in a cross shape. At this time, a second color region 302 is formed in a region between two parts of the first color region 301 distributed in a cross shape.

[0074] The first LED chip group 201 and the second LED chip group 202 are correspondingly disposed on the substrate 10 corresponding to the first color region 301 and the second color region 302 . Except for the above differences, other structures of this embodiment are the same as those of Embodiment 1.

[0075] In this embodiment, by adjusting the first adjustment switch K1 and the second adjustment switch K2 of the drive circuit, only one set of LED chipsets can be turned on selectively, or two sets of LED chipsets can be turned on at the s...

Embodiment 3

[0080] Such as Figure 5 As shown, the main difference between this embodiment and Embodiment 1 is that the phosphor film 30 includes a first color region 301 , a second color region 302 and a third color region 303 respectively distributed in a fan shape. The first color region 301 , the second color region 302 and the third color region 303 are joined together to form a circular phosphor film 30 .

[0081] The first LED chip group 201 , the second LED chip group 202 and the third LED chip group 203 are respectively disposed on the substrate 10 corresponding to the first color region 301 , the second color region 302 and the third color region 303 . Except for the above differences, other structures of this embodiment are the same as those of Embodiment 1.

[0082] In this embodiment, by adjusting the first adjustment switch K1, the second adjustment switch K2 and the third adjustment switch K3 of the drive circuit, only one group of LED chips can be turned on selectively, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com