Reciprocating rolling fire grate segment for garbage incinerator

A technology for waste incinerators and grate sheets, which is applied to incinerators, grate, combustion types, etc., can solve the problems of not greatly improving the service life of grate sheets and increasing costs, and achieves the effect of reducing friction coefficient and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

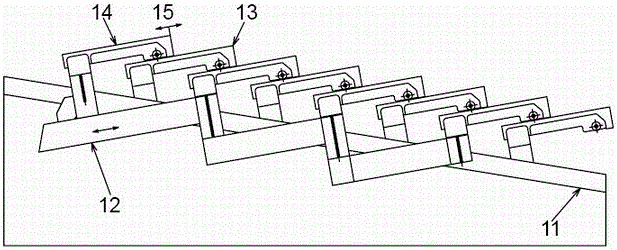

[0025] see Figure 1 to Figure 5 , the present invention provides a reciprocating rolling grate for a garbage incinerator, the grate is installed in the grate system, the fixed grate 13 is installed on the fixed bracket 11 of the grate, and the movable grate 14 is installed on the movable bracket of the grate 12 on. The grate pieces adopt the superposition form, and the movable support 12 moves back and forth to drive the mutual motion between the grate pieces.

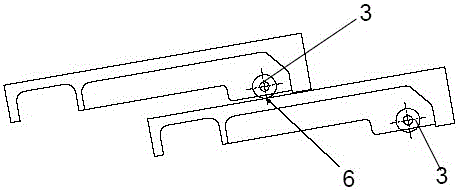

[0026] Such as image 3 with Figure 4 As shown in , the grate is equipped with a roller device, which is mainly composed of a heat-resistant casting body 1, a roller 3, a pin shaft 2 and a fastener 4. The heat-resistant casting body 1 is installed on the contact surface of the reciprocating motion of the grate, and the center of the roller 3 passes through the pin shaft 2. On the groove wall, install fastener 4 fastening roller 3 at pin shaft 2 ends then.

[0027] The movable fire grate piece 14 and the fixed fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com