Roller frying furnace

A frying furnace and drum technology, which is applied in the field of drum frying furnaces, can solve the problems of inconvenient daily cleaning and maintenance of equipment, difficulty in ensuring that customers order food, long processing time and cycle, etc., to save labor costs, facilitate maintenance and cleaning, and save energy. High utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

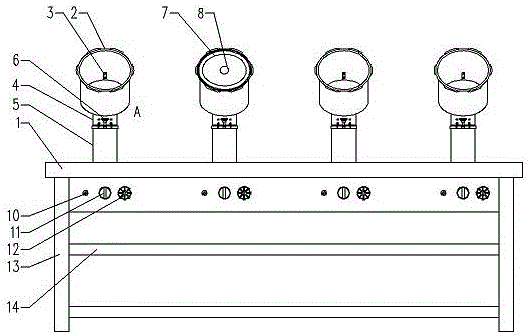

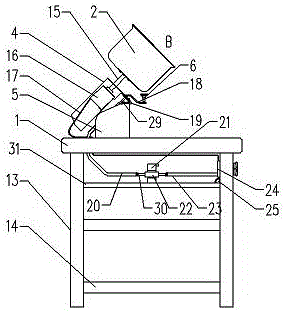

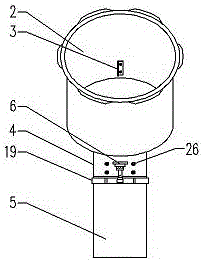

[0028] Implement 1, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the drum frying furnace includes an operating table 1, on which several independent frying pans 2 are arranged, and each frying pan 2 is tilted and can rotate around its own axis under the drive of the power drive device. The operating table 1 A burner 6 is respectively arranged at a position corresponding to the bottom of each frying pan 2 .

[0029] The axes of the several frying pans 2 are located on the same straight line and arranged side by side at a certain distance.

[0030] The working surface of the console 1 is a horizontal plane, and the inclination angle between the axis of the wok 2 and the working surface of the console 1 is 30-60 degrees, and the inclination angle is the best angle at 45 degrees, which is convenient for food to be heated. uniform.

[0031] The inclination angle between the axis of the wok 2 and the working surface of the console 1 is 45 degrees.

[0032] The...

Embodiment 2

[0045] Example 2, such as Figure 5 As shown, in the above-mentioned embodiment 1, a range hood 32 is arranged above the drum frying furnace, the range hood 32 is installed on the wall 42, a conductive heat absorbing device is installed on the range hood 32, and the wall 42 is close to the range hood 32 position solar collectors.

[0046] The conductive heat absorbing device includes a conductive heat absorbing layer 33 installed inside the range hood 32 cover, and a sensor is arranged in the conductive heat absorbing layer 33 for detecting the temperature, current and other characteristics of the conductive heat absorbing layer 33 .

[0047] A battery and charging assembly 36 and an electronic control system 37 are installed on the range hood 32 .

[0048] Described solar heat collection device comprises the solar heat collection that is installed in range hood 32 outlets below, power generation board 34, and solar heat collection, power generation board 34 is installed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com