On-line monitoring method and monitoring device for pulverized coal concentration in coalbed gas well output liquid

A technology for coalbed methane wells and produced fluids, applied in measuring devices, analysis of suspensions and porous materials, scientific instruments, etc., can solve the problems of unrealized on-line monitoring of coal powder content and loss of precision, etc., to facilitate coal powder cleaning and ensure Accurate and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

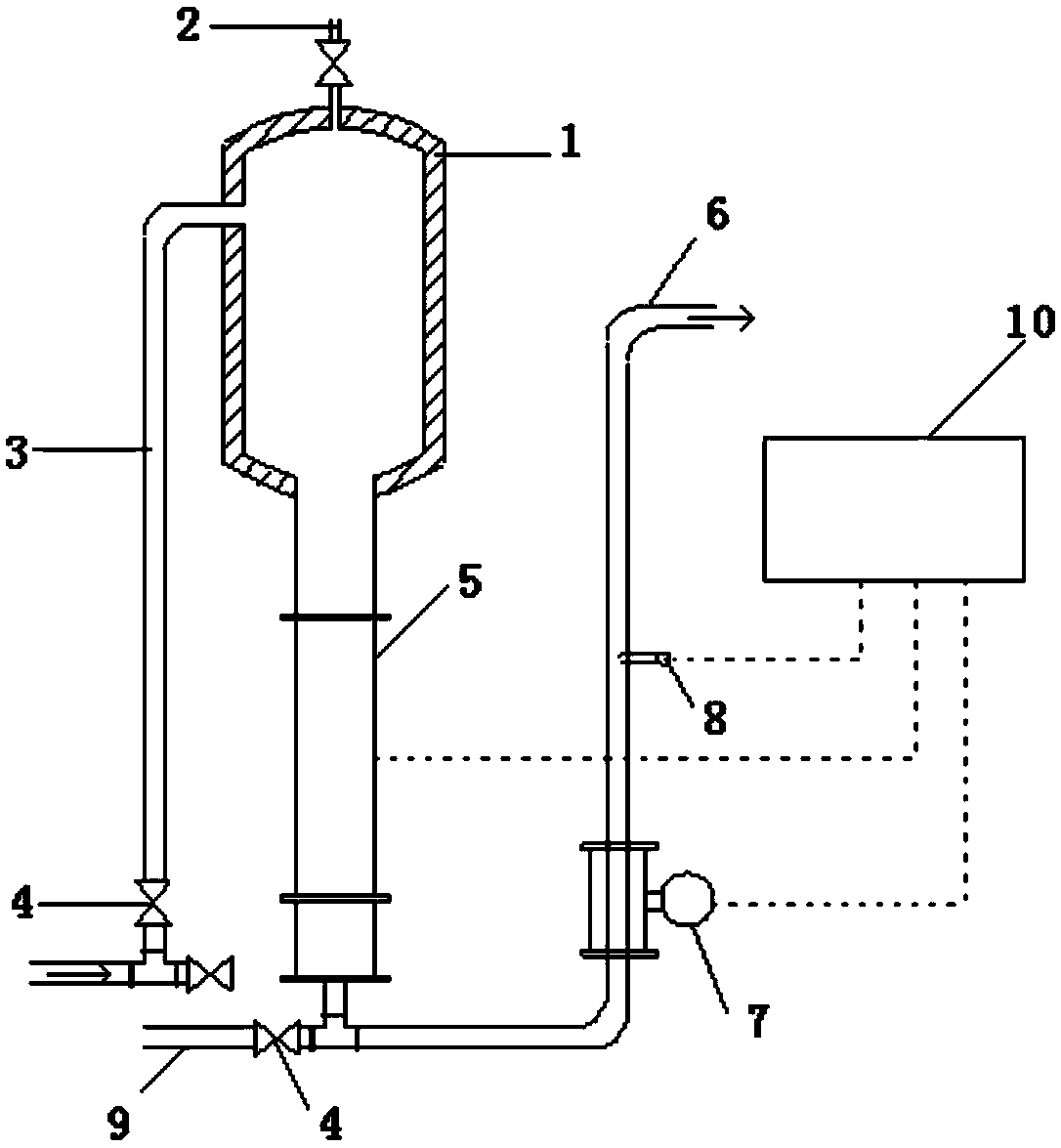

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

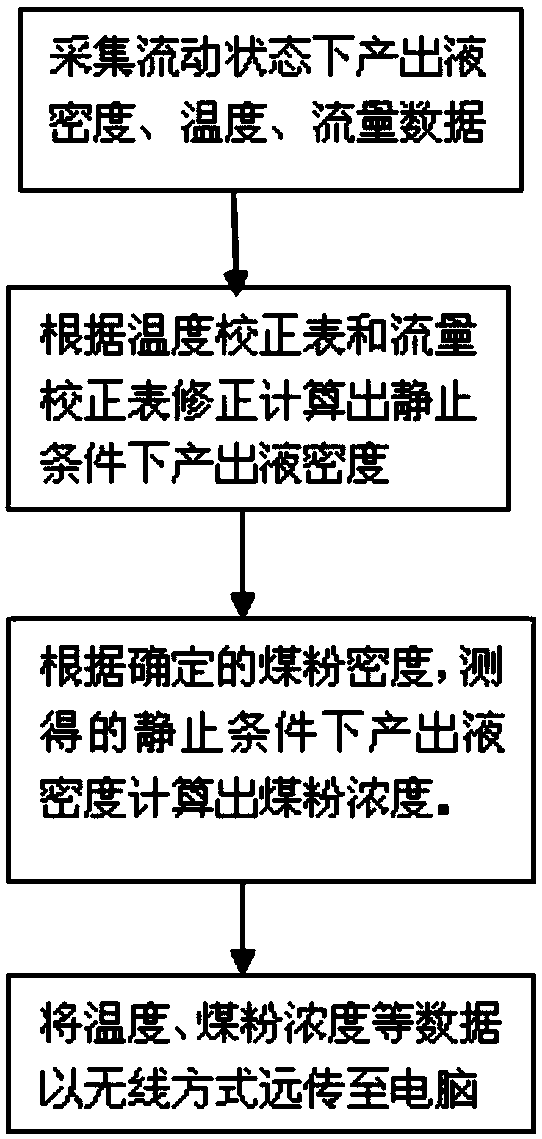

[0042] The method for on-line monitoring of coal bed gas well output liquid pulverized coal concentration of the present invention specifically comprises the following steps:

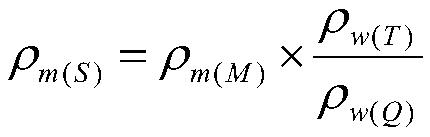

[0043] Step 1, determining the revised value of density and temperature of static formation water: the density values of the produced water of the coalbed methane well at different temperatures are obtained through indoor evaluation experiments, and a temperature correction table is drawn.

[0044]Step 2: Determine the revised value of density and flow rate of mobile formation water: obtain the density values of the produced water of the coalbed methane well at different temperatures and flow rates through indoor evaluation experiments, and draw a flow rate correction table.

[0045] Step 3, measuring the density of the produced liquid at the wellhead of the coalbed methane well under the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com