Remote control system for coal mining machine

A remote control system and control system technology, applied in the field of shearer control system, can solve the problems of backward technology, complex structure and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

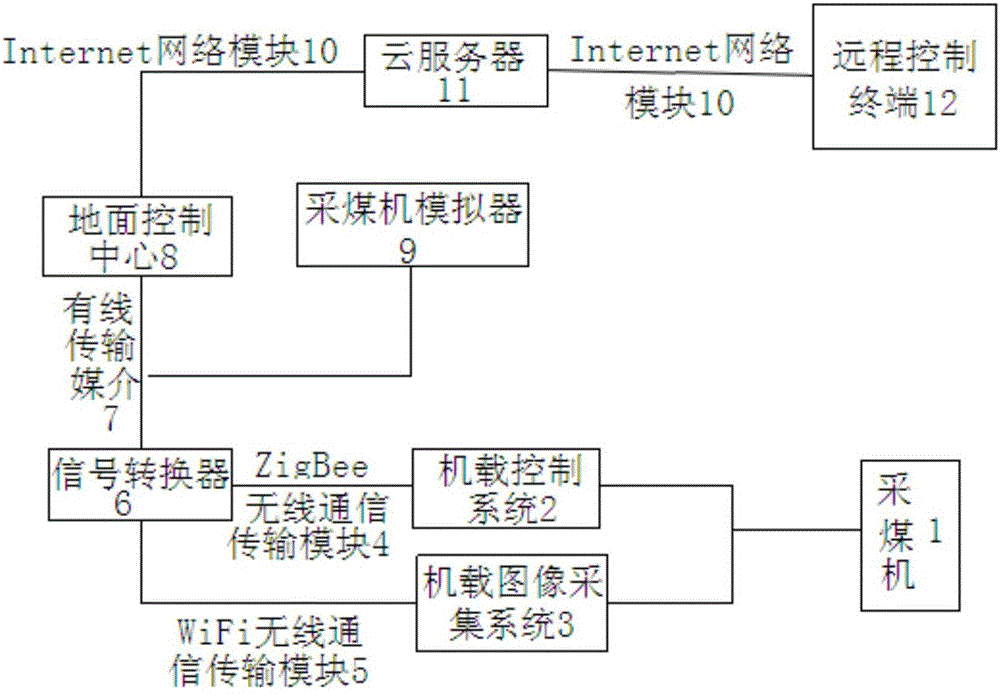

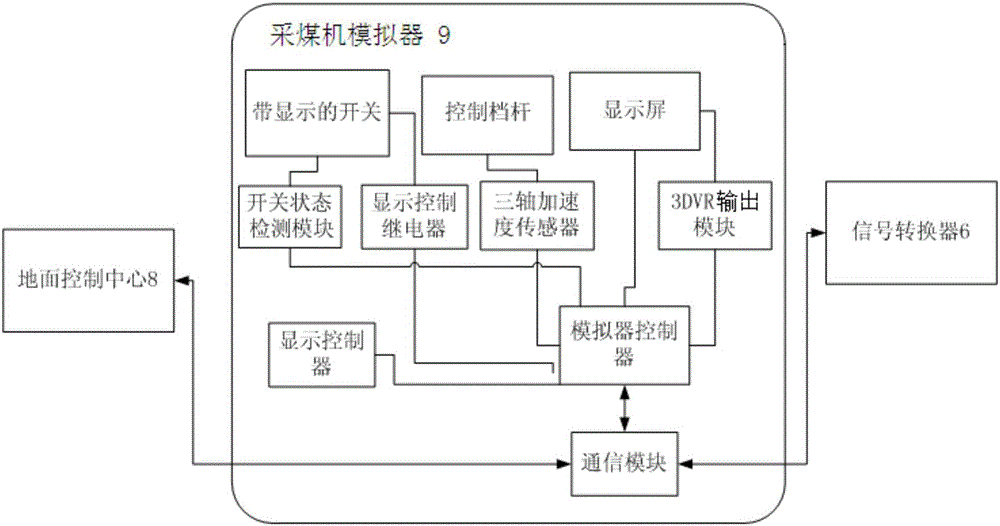

[0013] like figure 1 As shown, the present invention provides a remote control system of a coal shearer, which includes a coal shearer 1, an airborne control system 2, an airborne image acquisition system 3, a ZigBee wireless communication transmission module 4, a WiFi wireless communication transmission module 5, Signal converter 6 , wired transmission medium 7 , ground control center 8 , coal shearer simulator 9 , Internet network module 10 , cloud server 11 and remote control terminal 12 . Among them, coal shearer 1, airborne control system 2, airborne image acquisition system 3, ZigBee wireless communication transmission module 4, WiFi wireless communication transmission module 5 and signal converter 6 are located underground, ground control center 8, Internet network module 10 , cloud server 11, remote control terminal 12 and coal mining machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com