Construction method of back anchor type cantilever combined bracket structure

A technology of combining brackets and construction methods, which can be used in the erection/assembly of bridges, instruments, electrical digital data processing, etc., and can solve problems such as poor seismic performance flexibility and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

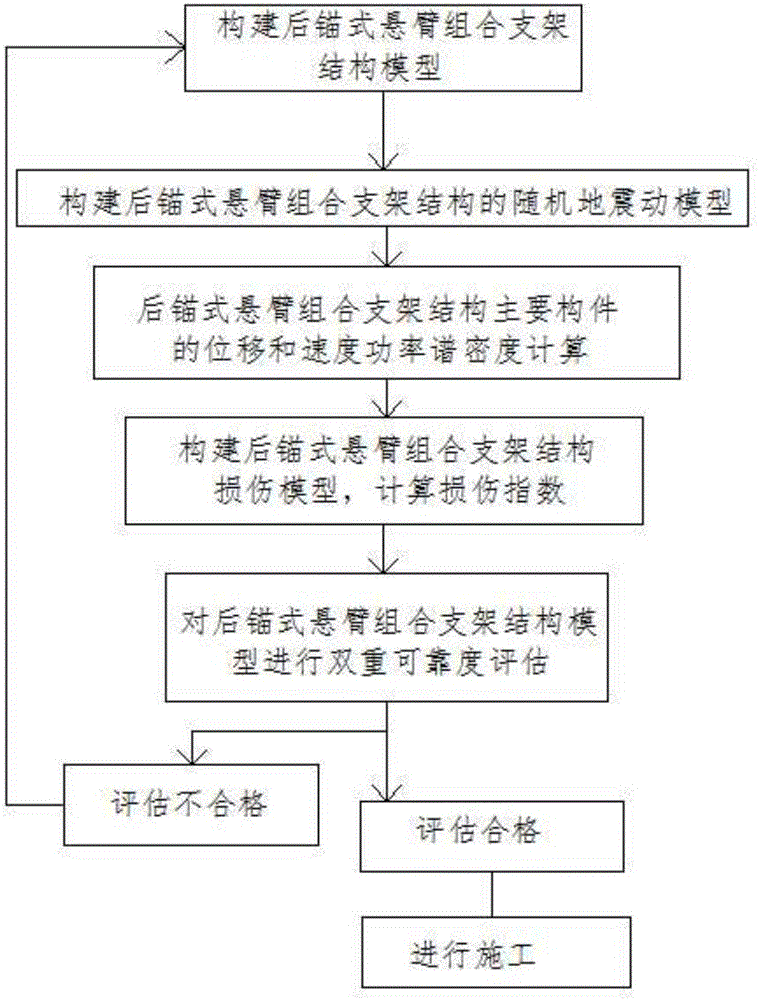

[0028] Embodiment 1: as figure 1 The construction method of the shown rear anchor type cantilever composite support structure comprises the following steps:

[0029] (1) Preliminarily construct the structural model of the post-anchor cantilever composite support through computer-aided design, and determine the main components of the post-anchor cantilever composite support structural model;

[0030] (2) According to the local seismic fortification intensity, seismic design grouping and site category of the post-anchor cantilever composite support structure, construct the random ground motion model of the post-anchor cantilever composite support structure model, and generate displacements and velocities corresponding to the main components power spectral density function;

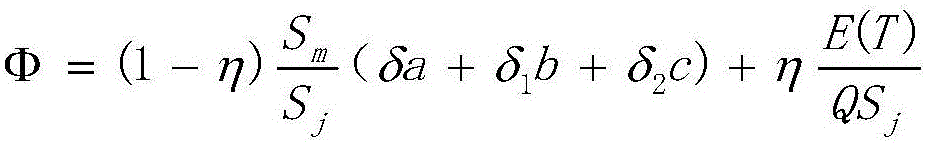

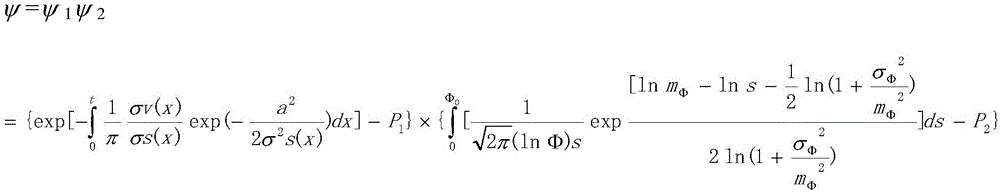

[0031] (3) Calculate the corresponding displacement power spectral density and velocity power spectral density according to the power spectral density function of the displacement and velocity of the main c...

Embodiment 2

[0047] Embodiment 2: as figure 1 The construction method of the shown rear anchor type cantilever composite support structure comprises the following steps:

[0048] (1) Preliminarily construct the structural model of the post-anchor cantilever composite support through computer-aided design, and determine the main components of the post-anchor cantilever composite support structural model;

[0049] (2) According to the local seismic fortification intensity, seismic design grouping and site category of the post-anchor cantilever composite support structure, construct the random ground motion model of the post-anchor cantilever composite support structure model, and generate displacements and velocities corresponding to the main components power spectral density function;

[0050] (3) Calculate the corresponding displacement power spectral density and velocity power spectral density according to the power spectral density function of the displacement and velocity of the main c...

Embodiment 3

[0066] Embodiment 3: as figure 1 The construction method of the shown rear anchor type cantilever composite support structure comprises the following steps:

[0067] (1) Preliminarily construct the structural model of the post-anchor cantilever composite support through computer-aided design, and determine the main components of the post-anchor cantilever composite support structural model;

[0068] (2) According to the local seismic fortification intensity, seismic design grouping and site category of the post-anchor cantilever composite support structure, construct the random ground motion model of the post-anchor cantilever composite support structure model, and generate displacements and velocities corresponding to the main components power spectral density function;

[0069] (3) Calculate the corresponding displacement power spectral density and velocity power spectral density according to the power spectral density function of the displacement and velocity of the main c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com