JFET and manufacturing method thereof

A manufacturing method and technology of conductivity type, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of unstable performance of JFET, large changes in substrate resistivity, low doping concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

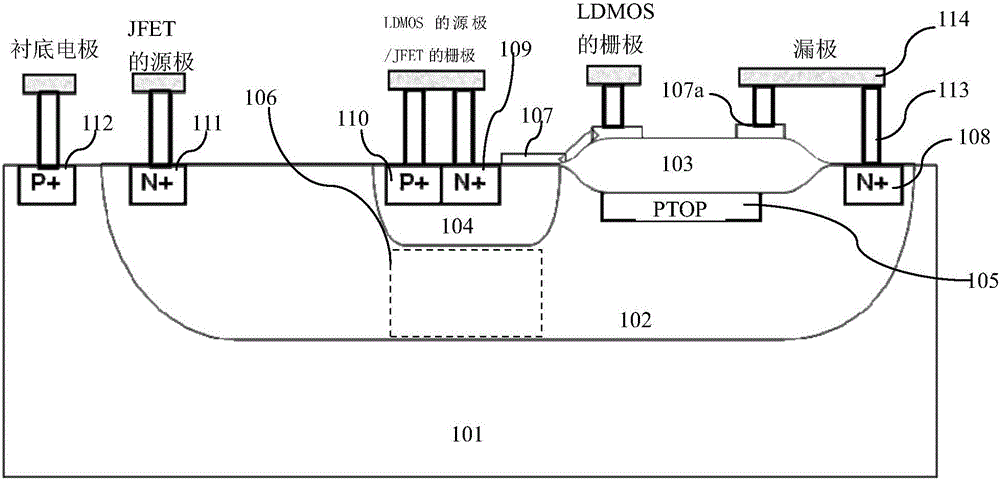

[0065] like figure 1 Shown is a schematic structural diagram of an existing JFET; JFET is integrated in LDMOS, taking an N-type device as an example, an N-type deep well 102 is formed in a P-type semiconductor substrate such as a P-type silicon substrate 101, and an N-type deep well 102 is formed in a P-type semiconductor substrate such as a P-type silicon substrate 101. A field oxide layer 103 is formed on the surface of the P-type silicon substrate 101 of the P-type deep well 102 . The P-type well region 104 is formed in the N-type deep well 102, and the P-type well region 104 is simultaneously used as the channel region of the LDMOS and the gate region of the JFET; a PTOP is formed on the surface of the N-type deep well 102 at the bottom of the field oxide layer 103 Layer 105. The N+ doped drain region 108 shared by JFET and LDMOS is formed on the surface of N-type deep well 102, and the drift region shared by JFET and LDMOS is composed of N-type deep well 102 between drai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com