Quasicrystal patterning transparent film electrode used for intelligent light modulation film

A transparent conductive film, intelligent dimming technology, used in circuits, electrical components, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Preparation of graphene / embedded quasicrystal patterned silver metal mesh composite transparent conductive thin film electrode

[0050] 1. Fabrication of Embedded Quasicrystalline Patterned Silver Metal Grids

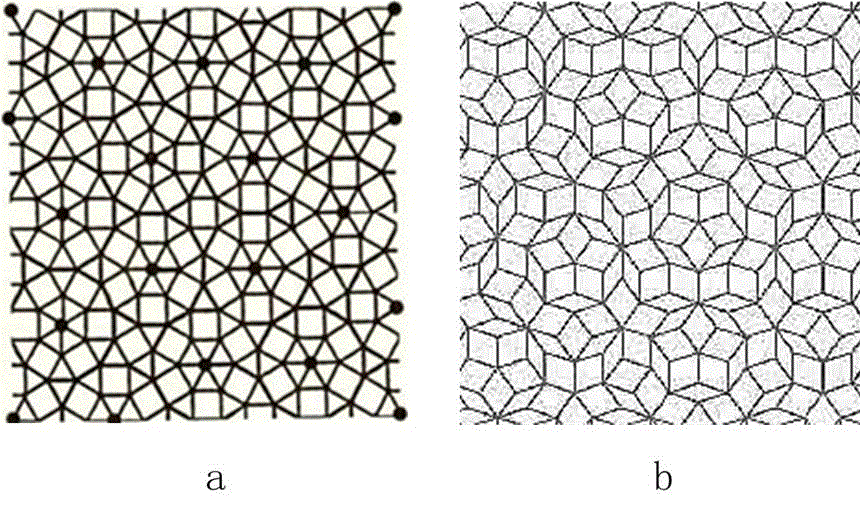

[0051] Coat a layer of UV-cured polymethyl methacrylate (PMMA Xinguang SKA-HC-1) on a 5cm*5cm PET (AICA, model HC2106) substrate, and then use the grid template (self-made, height is 10μm, the side length is 1mm, and the line width is 50μm, the shape is selected from figure 1 (b) The pattern shown) was placed on the PMMA glue and then cured by UV. After curing, the template is peeled off, and the conductive silver paste (Suzhou Lengshi, SNP-MM-03) is further filled in the groove part with a scraper, and the excess silver paste is scraped off with a scraper after filling. Then put the prepared plate into an oven at 150° C. and bake for 30 minutes. Its preparation process is as follows Figure 7 shown.

[0052] 2. Preparation of Graphene Layer

[0053] Put...

Embodiment 2

[0056] With the grid template of step 1 in Example 1, the parameters are set as a grid with a height of 10 μm, a side length of 0.5 mm, and a line width of 50 μm, and the remaining steps are consistent with Example 1 to prepare graphene / embedded quasicrystals Patterned silver metal mesh composite graphene transparent conductive film electrodes.

Embodiment 3

[0058] With the grid template of step 1 in Example 1, the parameters are set to a grid with a height of 10 μm, a side length of 2 mm, and a line width of 50 μm, and the remaining steps are consistent with Example 1 to prepare graphene / embedded quasicrystal patterns Silver metal grid composite transparent conductive film electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com