Preparation method for Al-Pd-Mn quasicrystal

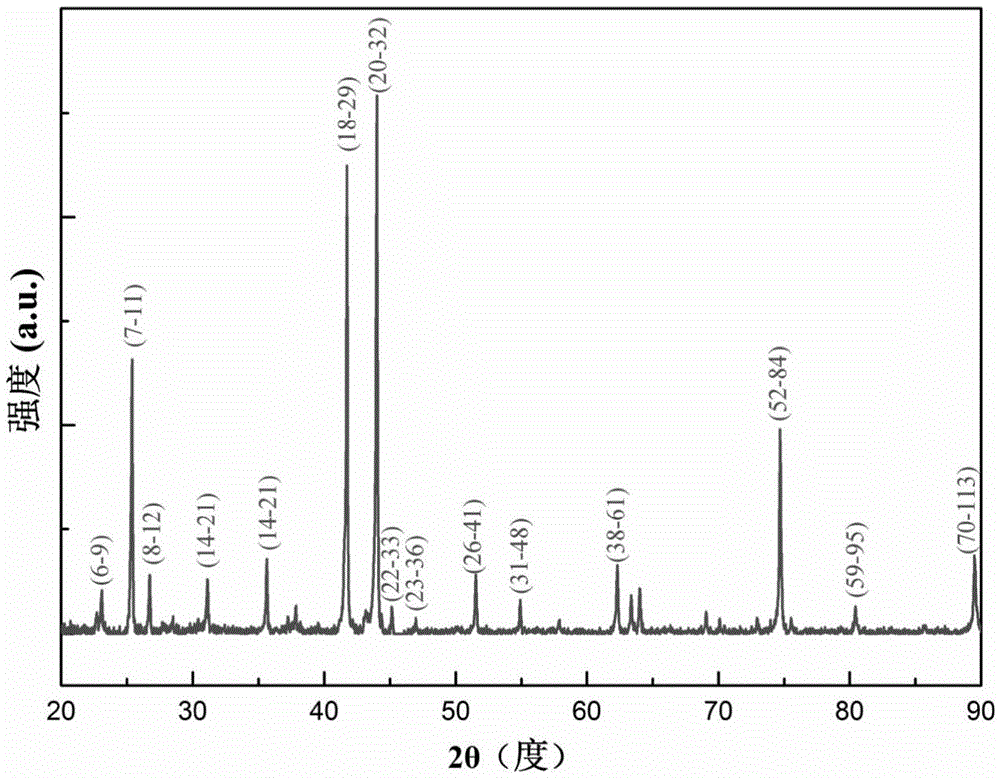

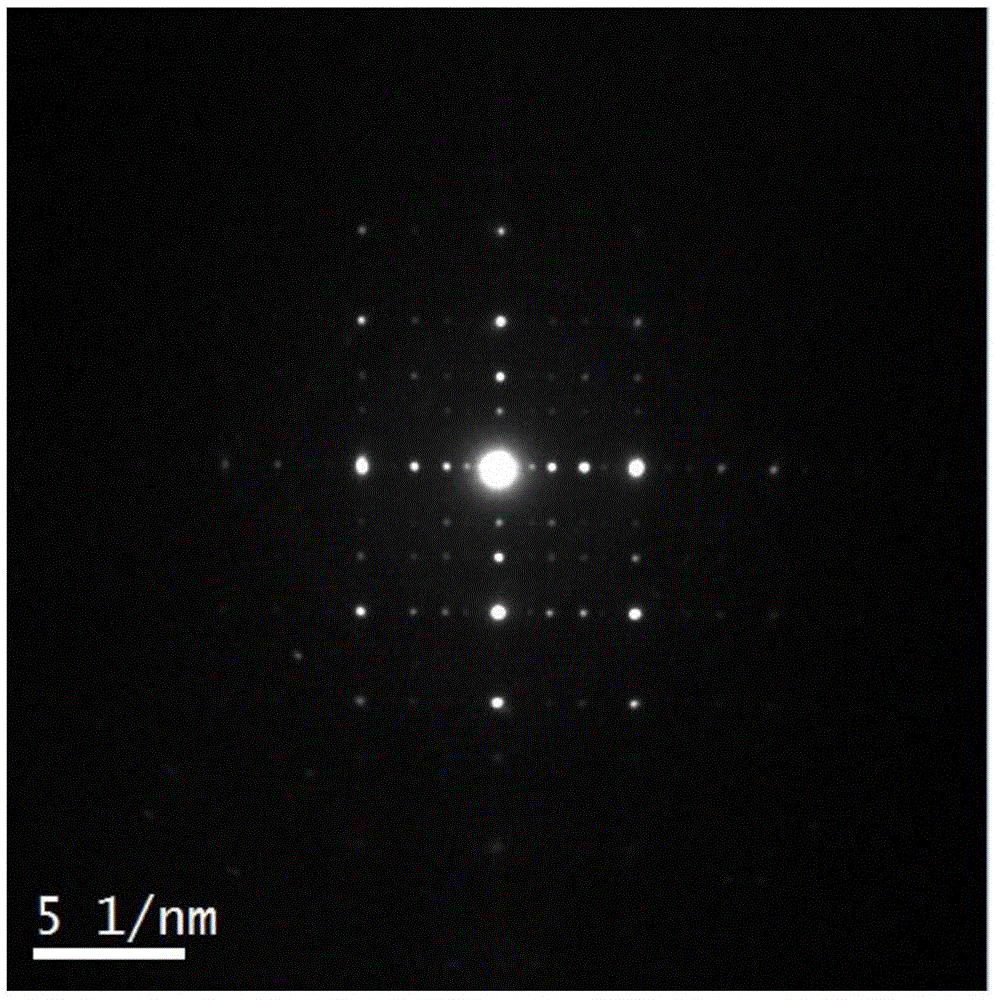

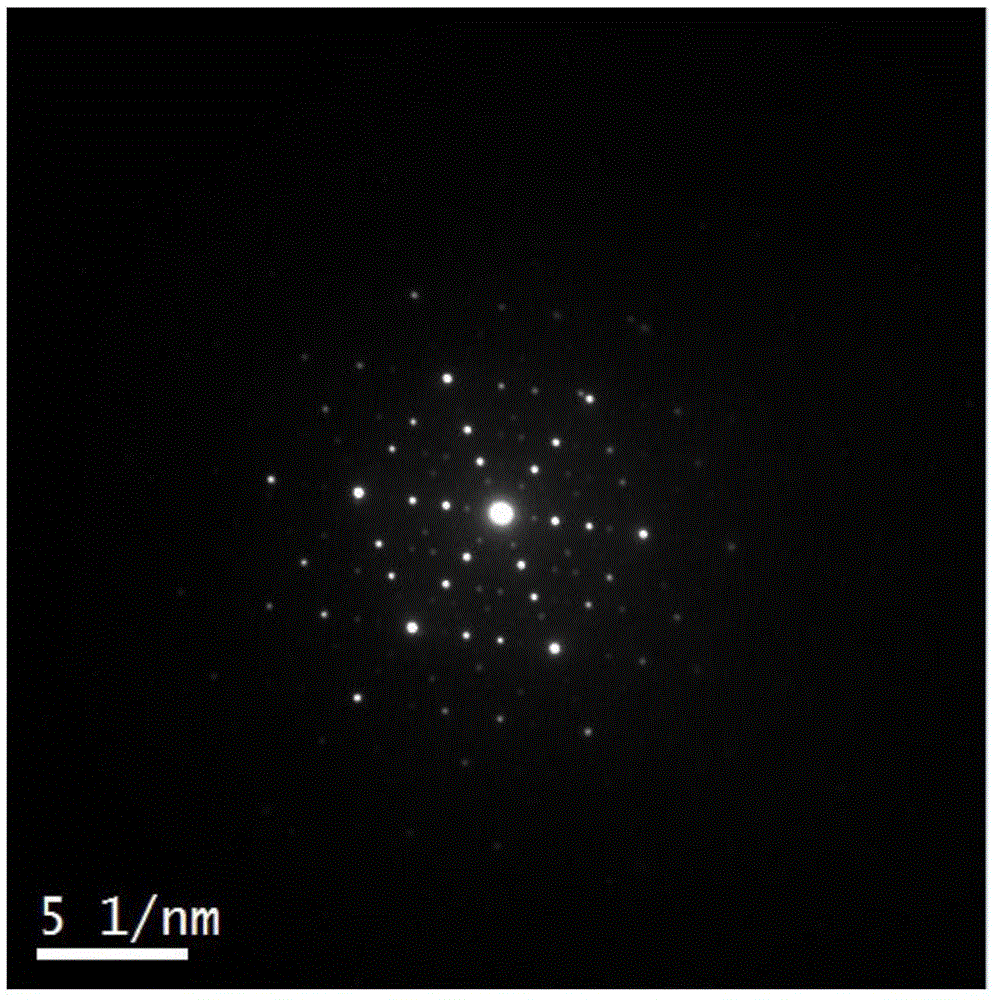

An al-pd-mn, quasicrystal technology, applied in the field of quasicrystal preparation, achieves the effects of high efficiency, high content of quasicrystal phase, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Calculate and weigh high-purity Al powder, Pd powder, Mn powder raw material according to atomic proportion, its weight is respectively 1.0076g, 1.1194g, 0.2601g (according to Al 71 PD 20 mn 9 Weigh), place the above powder in a mortar, thoroughly grind and mix evenly, and put it in a hard alloy mold with an inner diameter of Φ10.6mm, pressurize 4Mpa in a hydraulic tablet press for 120s, and obtain a diameter of Φ10.6mm Simple mechanical press-fit high-pressure preparatory blocks of thickness 7.6mm.

[0022] (2) The graphite furnace is a tubular furnace body with a height of 16.6mm and an outer diameter of Φ14mm and an inner diameter of Φ12.1mm. Both ends are sealed with a Φ12.06mm thick 3.3mm pyrophyllite sheet. The graphite furnace is equipped with a boron nitride crucible with a height of 10mm and an outer diameter of Φ12mm and an inner diameter of Φ10 .8mm, both ends are sealed with boron nitride sheets with a diameter of Φ10.75mm and a thickness of 1.2mm. Pu...

Embodiment 2

[0031] (1) Calculate and weigh high-purity Al powder, Pd powder, Mn powder raw material according to the atomic ratio, and its weight is respectively 1.0700g, 1.0551g, 0.3631g (according to Al 72 PD 18 mn 12 Weigh), place the above powder in a mortar, grind and mix it evenly, and put it in a hard alloy mold with an inner diameter of Φ10.6mm, pressurize 2Mpa in a hydraulic tablet press for 300s, and obtain a thickness of Φ10.6mm 7.6mm simple mechanical press fit high pressure prep block.

[0032] (2) The graphite furnace is a tubular furnace body with a height of 16.6mm and an outer diameter of Φ14mm and an inner diameter of Φ12.1mm. Both ends are sealed with a Φ12.06mm thick 3.3mm pyrophyllite sheet. The graphite furnace is equipped with a boron nitride crucible with a height of 10mm and an outer diameter of Φ12mm and an inner diameter of Φ10 .8mm, both ends are sealed with boron nitride sheets with a diameter of Φ10.75mm and a thickness of 1.2mm. Put the above-mentioned tu...

Embodiment 3

[0038](1) Calculate and weigh high-purity Al powder, Pd powder, Mn powder raw material according to atomic proportion, its weight is respectively 0.9826g, 1.1626g, 0.2001g (according to Al 70 PD 21 mn 7 Weigh), place the above powder in a mortar, thoroughly grind and mix evenly, put it in a hard alloy mold with an inner diameter of Φ10.6mm, pressurize 3Mpa in a hydraulic tablet press for 100s, and obtain a diameter of Φ10.6mm and a thickness 7.6mm simple mechanical press fit high pressure prep block.

[0039] (2) The graphite furnace is a tubular furnace body with a height of 16.6mm and an outer diameter of Φ14mm and an inner diameter of Φ12.1mm. Both ends are sealed with a Φ12.06mm thick 3.3mm pyrophyllite sheet. The graphite furnace is equipped with a boron nitride crucible with a height of 10mm and an outer diameter of Φ12mm and an inner diameter of Φ10 .8mm, both ends are sealed with boron nitride sheets with a diameter of Φ10.75mm and a thickness of 1.2mm. Put the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com