A chamber for encapsulating secreting cells

A cell and cavity sealing technology, applied in the field of bioartificial organs, can solve problems such as tearing and less obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

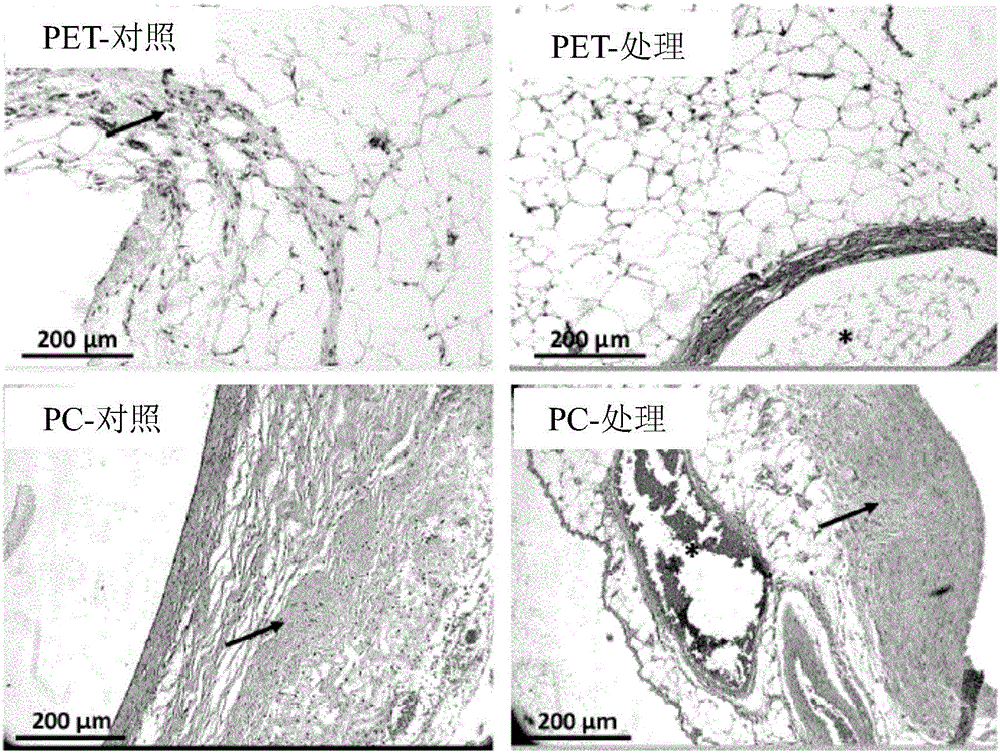

[0161] Embodiment 1: the manufacture of semi-permeable membrane

[0162] Membranes were fabricated by preparing two porous PET (poly(ethylene terephthalate)) layers from a biocompatible PET film by a "track-etching" process, which was then combined with Density nonwoven PET layer (located between two porous biocompatible PET layers) laminated. Thermal lamination is performed without the use of adhesives. One of the porous PET layers has a 2.10 9 to 7.10 9 hole / cm 2 The pore density, and the internal pore diameter of 10 to 30nm. The film has a thickness of 8 to 12 μm. Other porous PET layers have 10 7 to 5.10 7 hole / cm 2 The pore density, and the internal pore diameter of 400 to 600nm. The film has a thickness of 30 to 50 μm. The total thickness of the film is 200 μm or less.

Embodiment 2

[0163] Embodiment 2: surface treatment of film

[0164] The membrane prepared according to Example 1 was subjected to a surface treatment according to the protocol of Example 1 of WO2012 / 017337.

[0165] The membrane was functionalized with a first layer of heparin mixed with ethylcellulose (EC) solution and then covered with a layer of hydroxypropylmethylcellulose (HPMC).

Embodiment 3

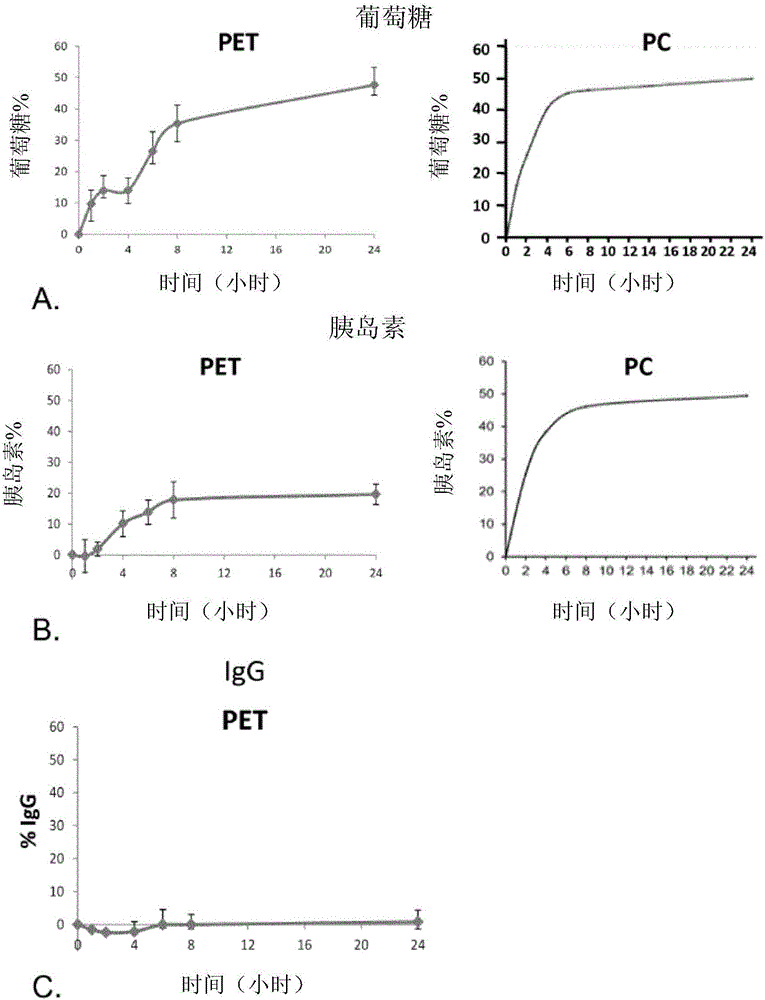

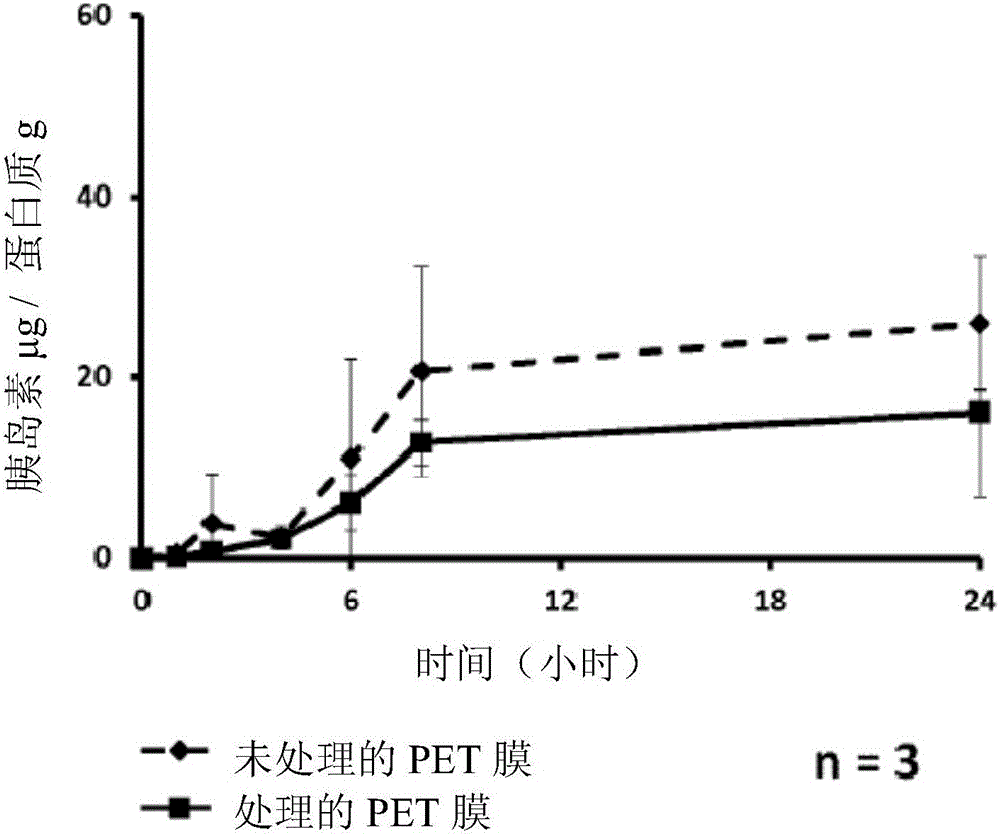

[0166] Example 3: Characterization of the permeability of the membrane

[0167]Glucose permeability, insulin permeability and immunoglobulin (IgG) permeability tests of previously prepared membranes were performed according to the following protocols:

[0168] Material

[0169] Diffusion chamber consisting of top and bottom compartments separated by a membrane (need to test for permeability) (tightness between the two compartments is provided by a seal), glucose (Fischer Scientific, Illkirch, France, number: G / 0500 / 53), NaCl, IgG (Sigma, Lyon, France, number: I9640), insulin (Sigma, number: I9278), distilled water.

[0170] Solution preparation

[0171] ·Normal saline

[0172] For 1 l: Dissolve 9 g of NaCl in 1 l of distilled water.

[0173] ·Glucose (4g / l)

[0174] For 1l: Dissolve 4g of glucose in 1l of normal saline.

[0175] IgG (5.75μg / ml)

[0176] For 60ml: Dilute 34.5ul IgG stock solution (10mg / ml) in 59.966ml saline.

[0177] Insulin (100μg / ml)

[0178] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com