Horizontal mushroom automatic bagging machine

A technology of edible fungus and bagging machine, which is applied in application, horticulture, agriculture, etc. It can solve the problems of low bagging efficiency, the appearance of machines and other people, and the increase of miscellaneous bacteria, so as to reduce the probability of miscellaneous bacteria being introduced and adjust and ease of use, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

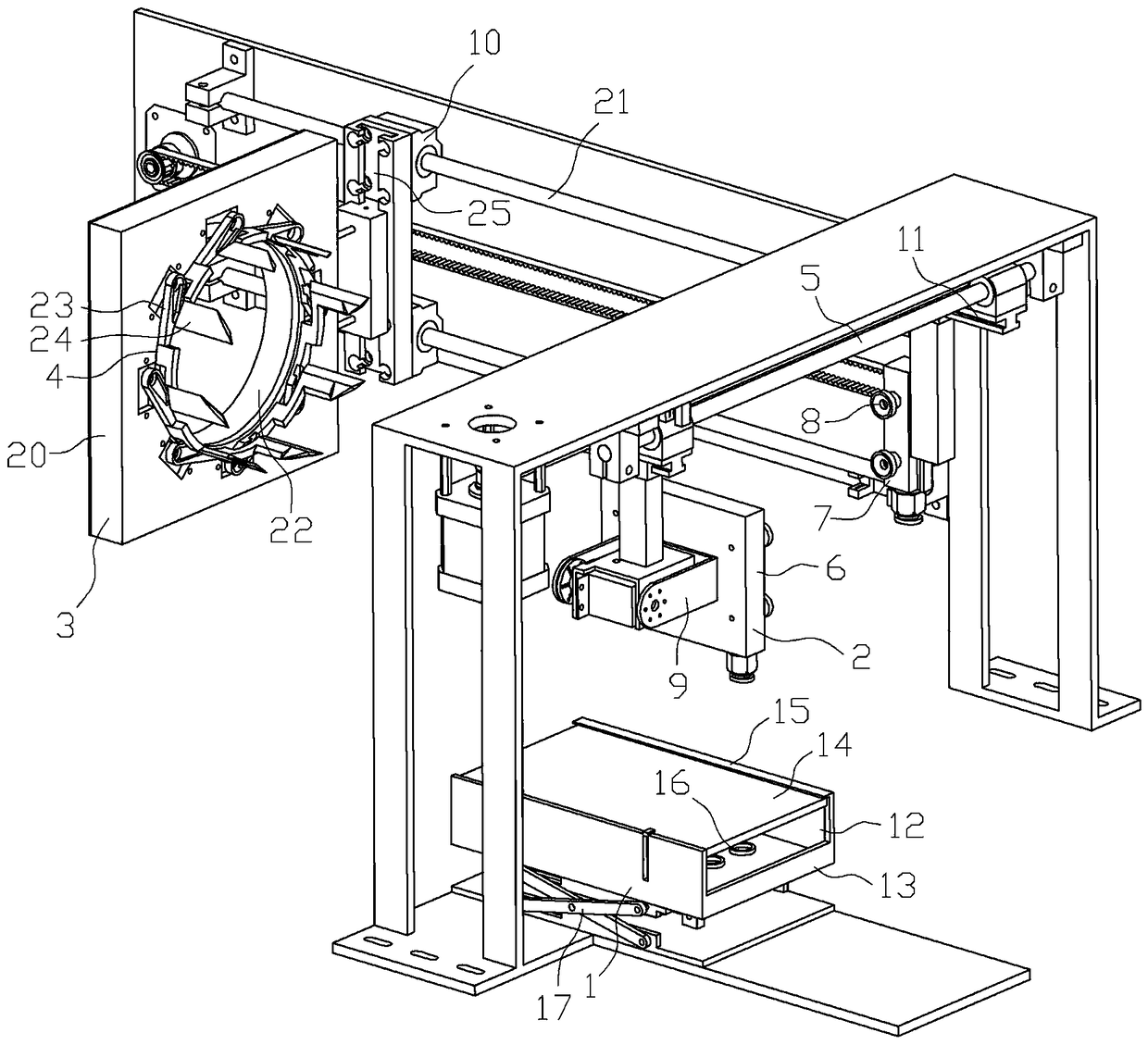

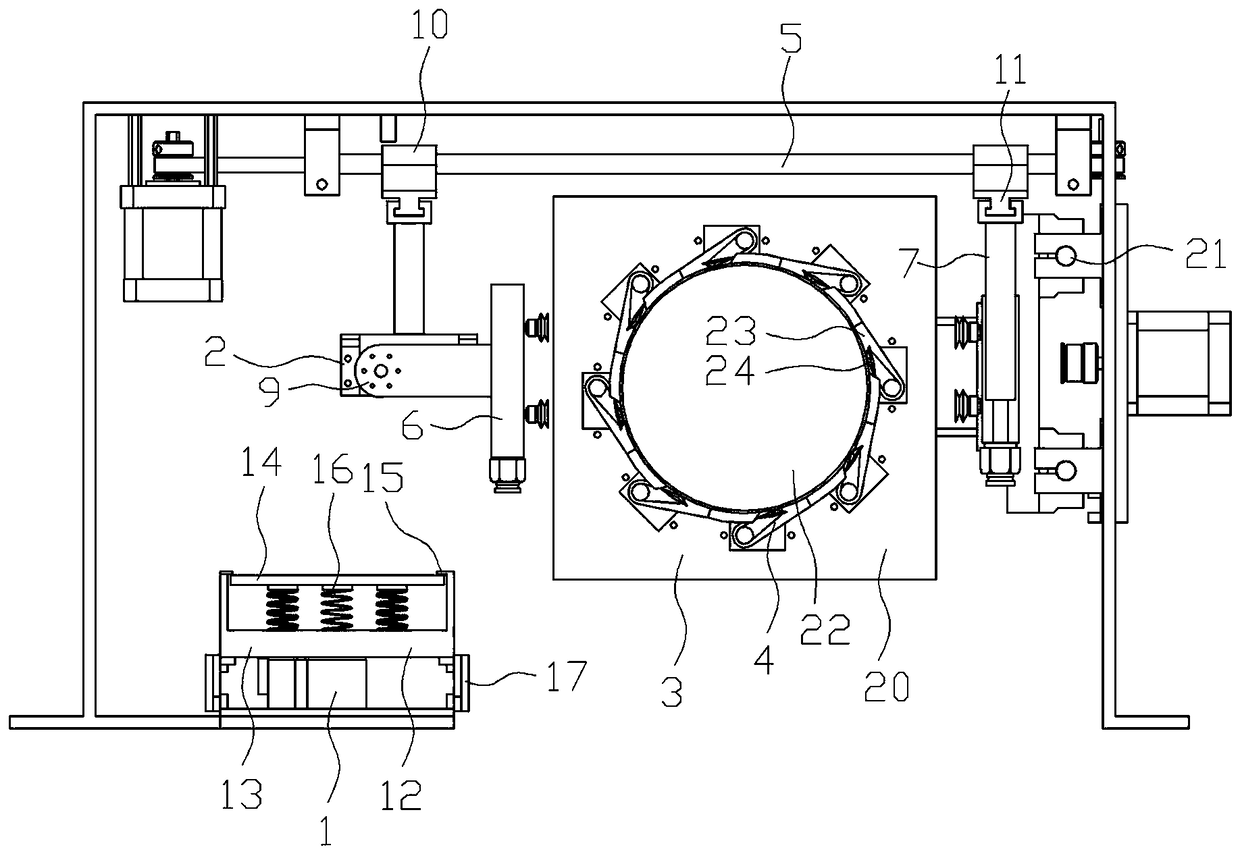

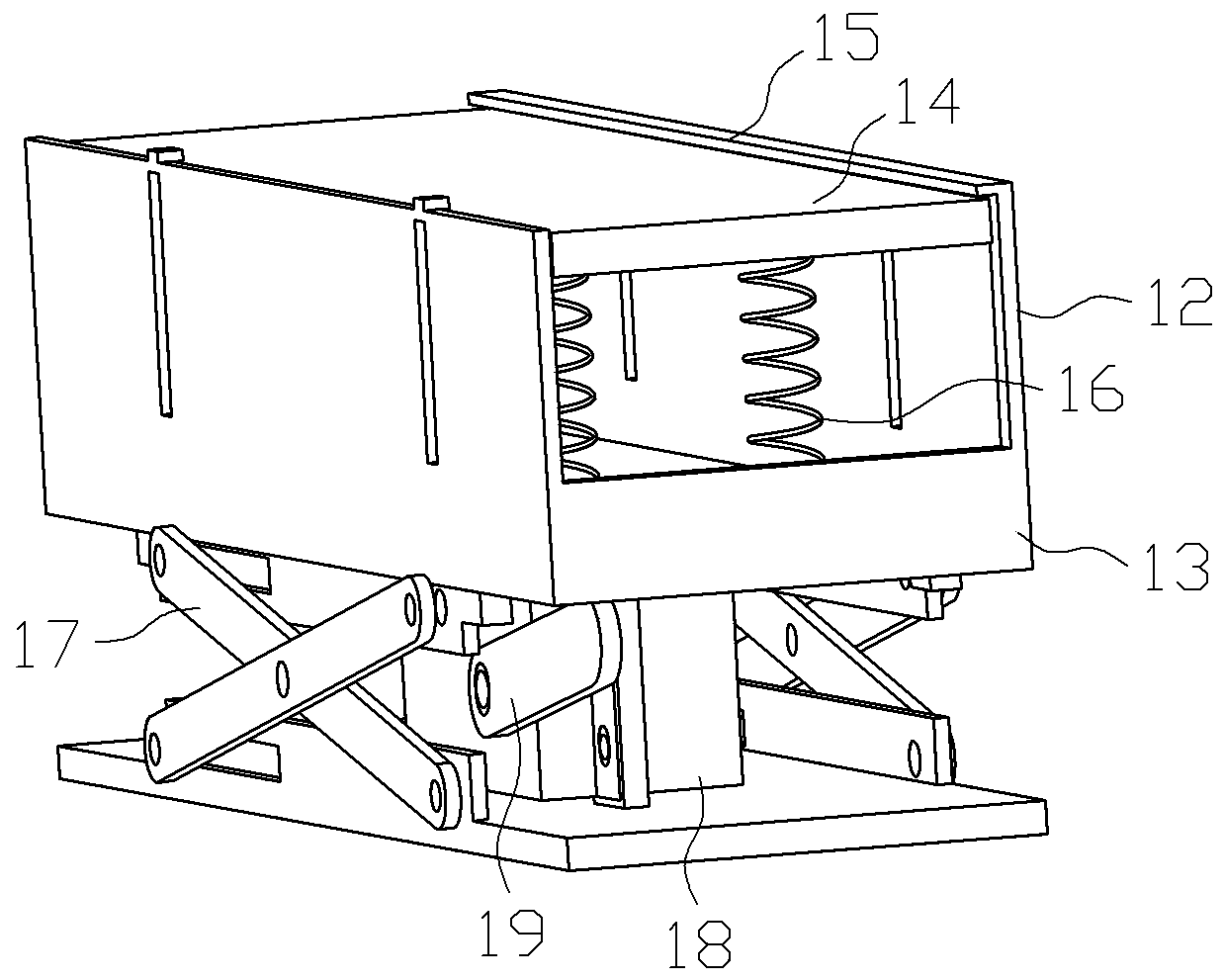

[0009] like figure 1 , 2 Shown in and 3, the horizontal edible fungus automatic bagging machine includes a bag supply mechanism 1, a bag taking mechanism 2 and a bagging mechanism 3, and the bag taking mechanism 2 is used to remove the fungus bag from the bag supply mechanism 1, and The mouth of the bag is opened, and the opening assembly 4 of the bagging mechanism 3 is inserted to tighten the mouth of the bag, and then the bacteria bag is placed on the discharge port of the bagging machine. 1, the horizontal guide rail 5 above and the bag-taking suction cup assembly 6 and the opening suction cup assembly 7, the bag-taking suction cup assembly 6 and the opening suction cup assembly 7 are provided with a number of suction ports 8 connected to the suction device, and both pass through The driving device is fixed on the transverse guide rail 5 so that it can move in opposite directions. The bag-taking suction cup assembly 6 is provided with a rotating part 9 controlled by the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com