Inorganic powder surface treatment method, electroless plating activator, polymer product, and polymer product surface selective metallization method

A surface treatment agent and surface treatment technology, applied in liquid chemical plating, surface pretreatment, metal material coating process, etc., can solve the problems of damage to the coating layer, poor compatibility, easy introduction of impurity ions, etc., and achieve optimization. Impact strength, avoid agglomeration, reduce the effect of introduction probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0104] In the following preparation examples, preparation comparative examples, examples and comparative examples, inductively coupled plasma emission spectrometry (ICP) was used to determine the composition of the electroless plating activator.

[0105] In the following examples and comparative examples, a commercially available laser particle size tester from Chengdu Jingxin Powder Testing Equipment Co., Ltd. was used to measure the average particle size of the electroless plating activator, which is the volume average particle size.

preparation example 1-11

[0107] It is used to illustrate the surface treatment method of the inorganic powder of the present invention.

preparation example 1

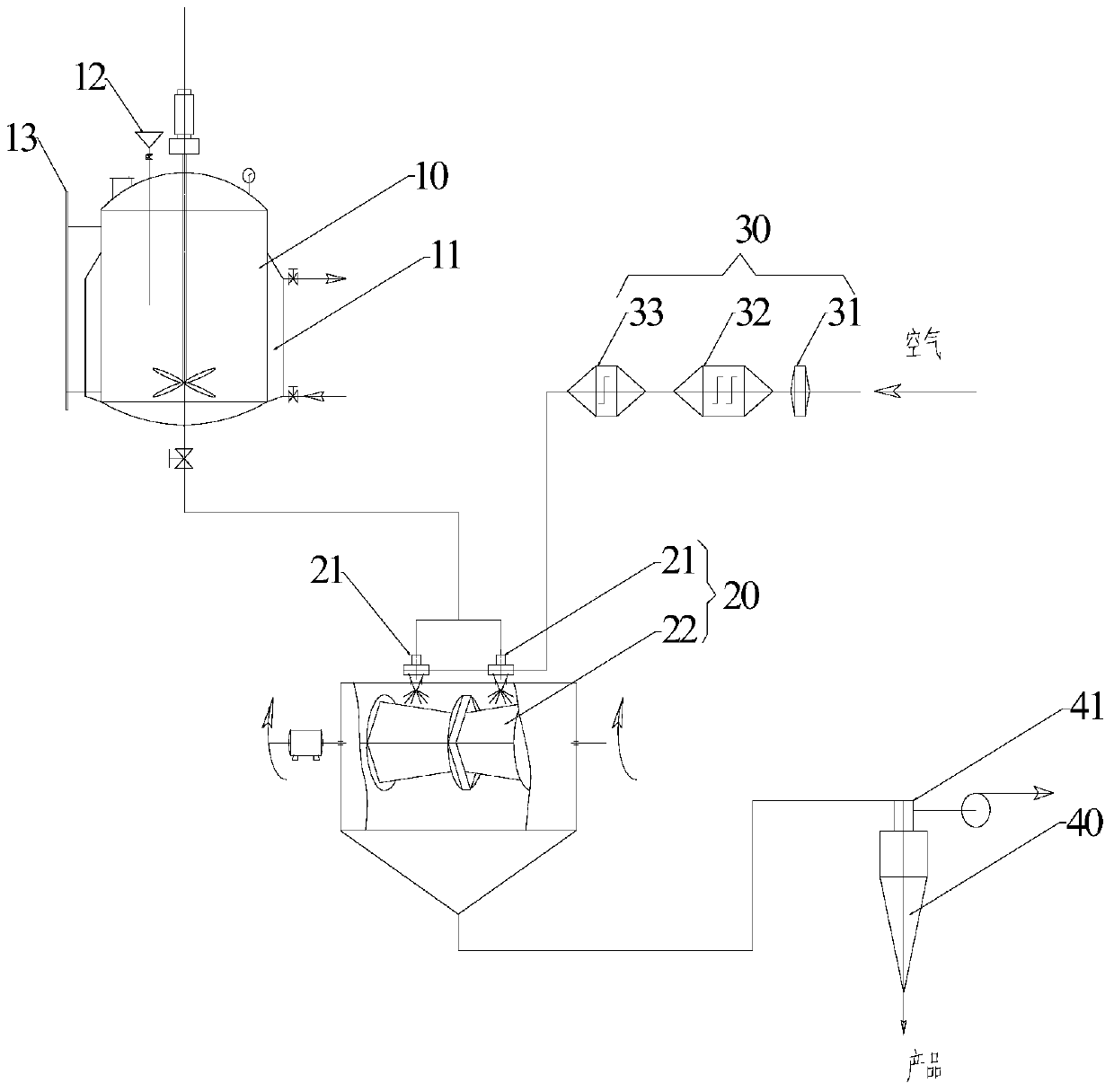

[0109] use figure 1 Surface treatment equipment for medium and inorganic powders, take 50kgCu 3 (PO 4 ) 2 Powder (commercially purchased from Xilong Chemical Co., Ltd., particle size D 50 2.1 μm) is poured into the mixing device 10, and the ionized water of getting 100L is poured into the kettle and covers the feeding port, and the stirrer in the mixing device 10 is opened (stirring speed is 100r / min, and the stirring and mixing time is 5min), and at the same time Fill the thermal insulation jacket 11 of the mixing device 10 with hot water at 60°C so that the temperature of the inner cavity of the mixing device 10 reaches the range of 55-60°C; Adding a concentration of 4wt% boric acid-deionized aqueous solution, wherein, relative to 100 parts by weight of Cu 3 (PO 4 ) 2 powder, boric acid as B 2 o 3 The calculated dosage is 5 parts by weight; after the feeding is completed, add an appropriate amount of dispersant, and continue stirring and mixing for 0.5 h to form a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com