Release agent and preparation method and application thereof

A technology of release agent and thickener, which is applied in the field of release agent and its preparation to achieve the effects of strengthening the edge, improving the yield of green embryos, and reducing the residual rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

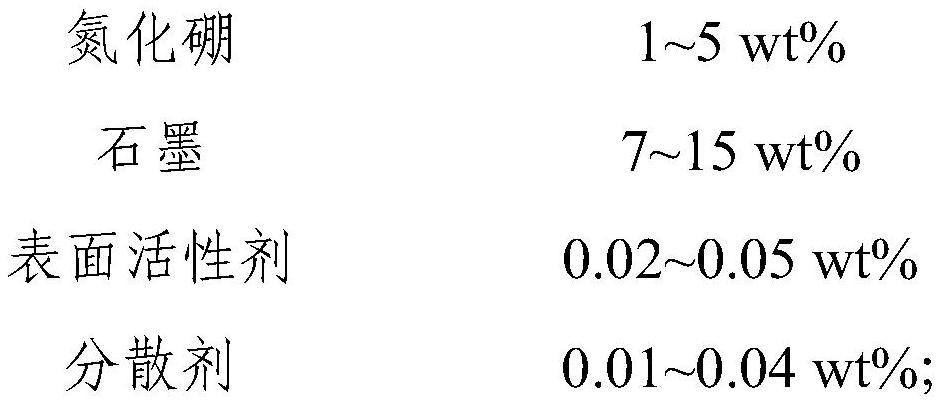

[0056] This embodiment provides a release agent, including the following components in mass percentage:

[0057]

[0058] Wherein, the pH value of the release agent is 8.

[0059] The present embodiment provides the preparation method of above-mentioned release agent simultaneously, comprises the steps:

[0060] (1) After mixing the polyacrylic resin emulsifying thickener and xanthan collagen, adjust the viscosity to 4200cps, and stir at 30r / min for 120min to form a suspension-free milky viscous liquid;

[0061](2) After boron nitride and graphite are mixed, the mixture is added to the non-suspension-free opalescent viscous liquid several times in a small amount, the stirring rate is adjusted to 50 r / min, and the stirring is uniform to obtain the premixed viscous liquid I;

[0062] (3) Add carboxymethyl cellulose and polycarboxylate ammonium salt macromolecular dispersant successively to the premixed viscous liquid I, and use ammonium citrate and citric acid pH buffering p...

Embodiment 2

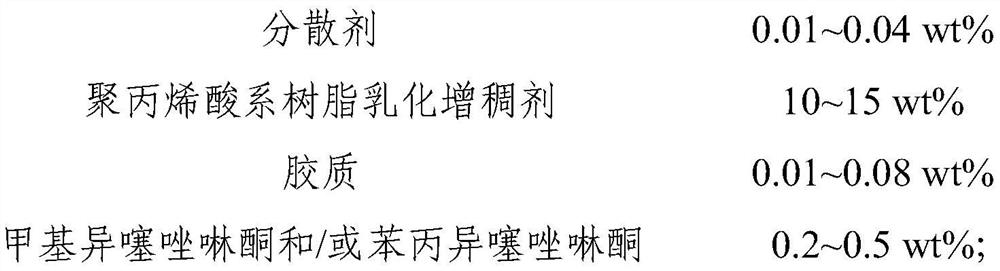

[0066] This embodiment provides a release agent, including the following components in mass percentage:

[0067]

[0068] Wherein, the pH value of the release agent is 8.

[0069] The present embodiment provides the preparation method of above-mentioned release agent simultaneously, comprises the steps:

[0070] (1) After mixing the polyacrylic resin emulsifying thickener and xanthan collagen, adjust the viscosity to 4200cps, and stir at 30r / min for 120min to form a suspension-free milky viscous liquid;

[0071] (2) After boron nitride and graphite are mixed, the mixture is added to the non-suspension-free opalescent viscous liquid several times in a small amount, the stirring rate is adjusted to 50 r / min, and the stirring is uniform to obtain the premixed viscous liquid I;

[0072] (3) Add carboxymethyl cellulose and polycarboxylate ammonium salt macromolecular dispersant successively to the premixed viscous liquid I, and use ammonium citrate and citric acid pH buffering ...

Embodiment 3

[0076] This embodiment provides a release agent, including the following components in mass percentage:

[0077]

[0078] Wherein, the pH value of the release agent is 8.

[0079] The present embodiment provides the preparation method of above-mentioned release agent simultaneously, comprises the steps:

[0080] (1) After mixing the polyacrylic resin emulsifying thickener and guar gum, adjust the viscosity to 4500cps, and stir at 60r / min for 120min to form a milky viscous liquid without suspension;

[0081] (2) After mixing boron nitride and graphite, add the mixture to the non-suspension milky viscous liquid several times in small amounts, adjust the stirring speed to 60 r / min, and stir evenly to obtain the premixed viscous liquid I;

[0082] (3) Add carboxymethyl cellulose and polycarboxylate ammonium salt macromolecular dispersant successively to the premixed viscous liquid I, and use ammonium citrate and citric acid pH buffering pair as pH regulator to adjust the syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com