Preparation method of high-concentration superfine silver powder

An ultra-fine silver and high-concentration technology, which is applied in the field of preparation of high-concentration ultra-fine silver powder, can solve the problems of increased equipment cost and management cost, high waste water treatment cost, unstable expansion quality, etc., so as to reduce the discharge of production waste liquid. , Easy to operate, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

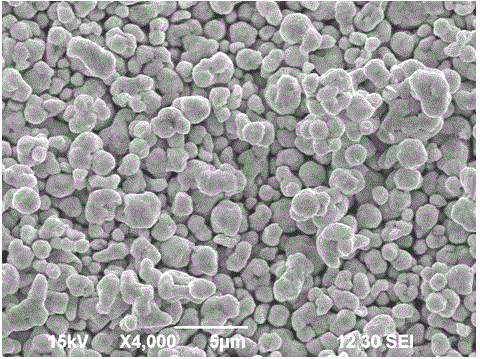

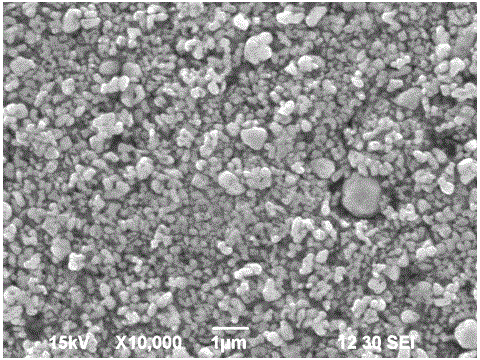

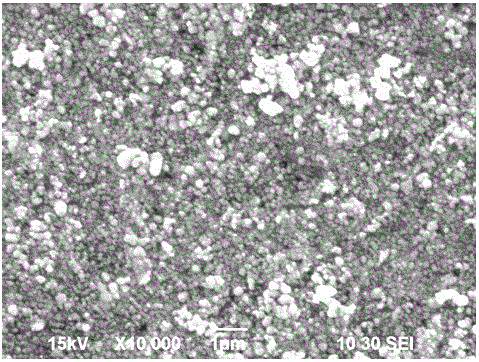

Image

Examples

Example Embodiment

[0032] In order to solve the above problems, the present invention provides a method for preparing high-concentration ultrafine silver powder, which specifically includes the following steps:

[0033] Prepare solution reaction system A containing silver ions, reducing agent and dispersant solution B respectively, and keep them at 10-200℃;

[0034] Under stirring, A and B are mixed and reacted to obtain a precipitated powder. The obtained precipitated powder is collected by a solid-liquid separation device, washed and dried, and the obtained powder is sieved to obtain high-concentration ultrafine silver powder.

[0035] In a preferred embodiment, the silver ion-containing solution reaction system A includes a silver-containing material and a solvent, the silver ion concentration is 250-1000 g / l, and the solvent is deionized water, absolute ethanol or Anhydrous hexanol. In the solution reaction system A containing silver ions of the present invention, the concentration of silver ions ...

Example Embodiment

[0044] Implementation mode:

Example Embodiment

[0045] Embodiment 1, a method for preparing high-concentration ultrafine silver powder, specifically includes the following steps:

[0046] Prepare solution reaction system A containing silver ions, reducing agent and dispersant solution B respectively, and keep them at 10-200℃;

[0047] Under stirring, A and B are mixed and reacted to obtain a precipitated powder. The obtained precipitated powder is collected by a solid-liquid separation device, washed and dried, and the obtained powder is sieved to obtain high-concentration ultrafine silver powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap