Double-station electric heating cutter device for materials

An electric heating, double-station technology, applied in shearing devices, manufacturing tools, metal processing equipment, etc., can solve the problems of uneven cutting, uneven material thickness, uneven section, etc., to achieve convenient uneven thickness, application Wide range of effects with high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

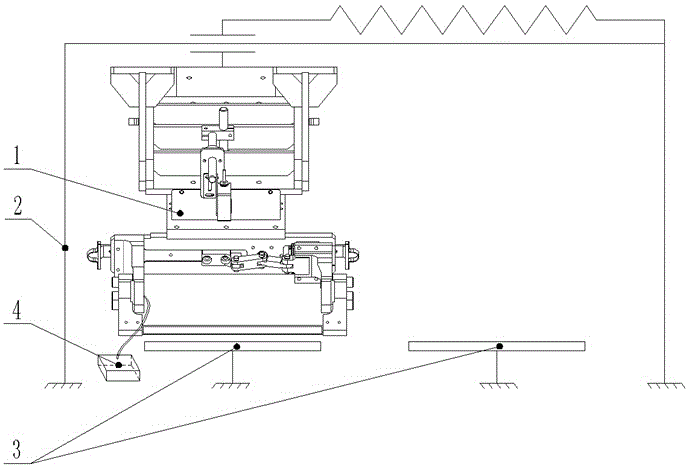

[0019] Such as figure 1 As shown, a dual-station material electric heating cutter device includes an electric heating cutter device 1, a portal frame 2, and a dual station worktable 3. The electric heating cutter device 1 is mounted on the portal frame 2 , It can slide on the portal frame 1 through the slide rail to realize the conversion between the two stations of the double-station workbench 3, and the two stations can be fabricated separately to improve production efficiency.

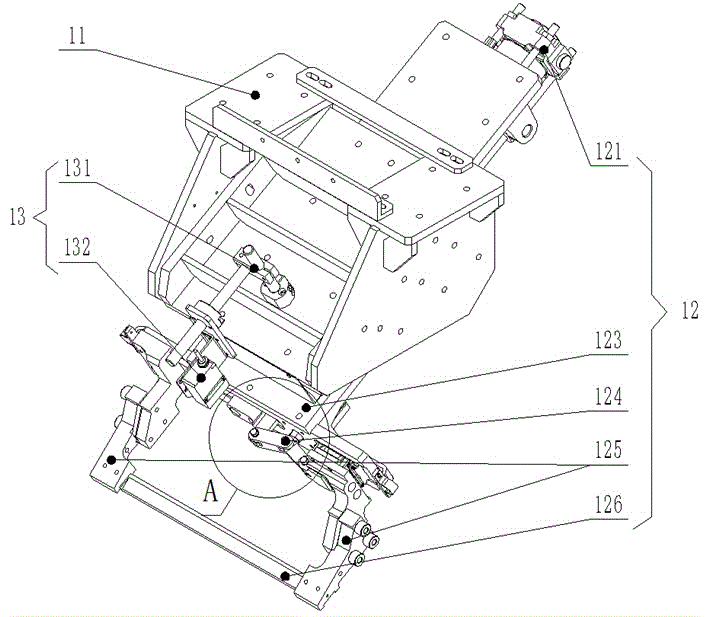

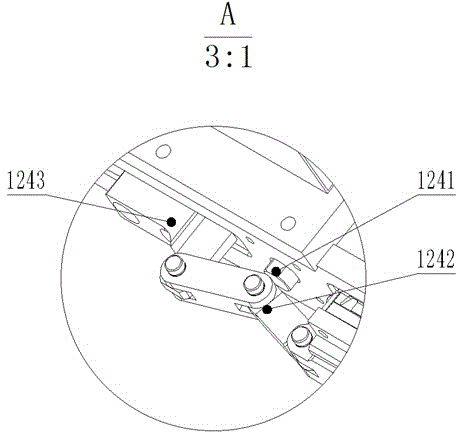

[0020] Such as figure 2 , Figure 4 As shown, the electric heating cutter device 1 includes a connecting bracket 11, an electric heating cutter mechanism 12, and a sensor assembly 13. The connecting bracket 11 is slidably connected under the door frame 2, and the electric heating cutter mechanism 12 is fixed under the connecting bracket 11. And it is at a certain angle to the horizontal plane for cutting materials. The sensor assembly 13 is fixed above the connecting bracket 11 to monitor the heating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com