Coating wastewater deeply treating and recycling device

A waste water and waste water tank technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as failure to meet discharge standards, unstable effluent quality, etc., and achieve effluent Excellent water quality, good effluent water quality and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

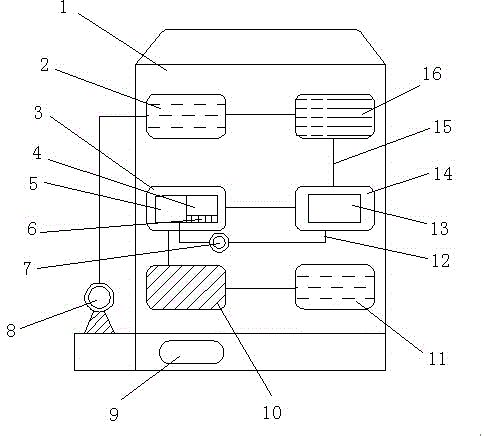

[0018] The present embodiment comprises body 1 and water pump 8, and water pump 8 is positioned at the side of body 1, and body 1 comprises waste water tank 2, regulating pond 16, flocculation reaction pond 14, biochemical pond 3, filter pond 10, clean water tank 11, pipeline 15 and The electric control box 9 is located at the bottom of the body 1, one end of the waste water tank 2 is connected to the top of the water pump 8, the other end is connected to one end of the regulating tank 16, the bottom of the regulating tank 16 is connected to the top of the flocculation reaction tank 14, and the flocculation One end of the reaction pool 14 is connected to one end of the biochemical pool 3, the bottom end of the biochemical pool 3 is connected to the top end of the filter tank 10, and the activated sludge method is used to remove the sludge, and one end of the filter tank 10 is connected to one end of the clean water tank 11. The above connection method All are connected by pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com