Vivianite crystal front dephosphorization method based on AAO/AO process

A blue iron ore and process technology, which is applied in the field of phosphorus removal and phosphorus removal before crystallization of blue iron ore, can solve the problems of great influence on the effect of nitrogen and phosphorus removal, change of biological sludge characteristics, and unsatisfactory phosphorus removal effect, etc. Achieve the effects of wide application range, recovery and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

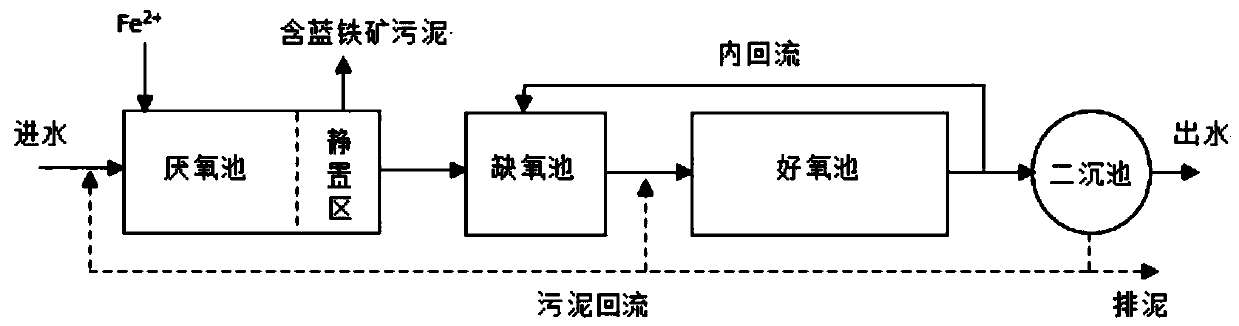

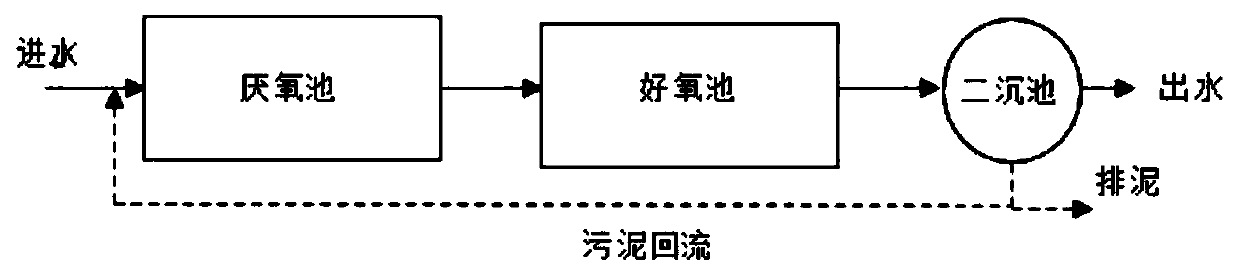

[0025] A pre-phosphorus removal method for blue iron ore crystallization based on the AAO process. The steps are: the raw sewage (influent) and all the sludge returned from the secondary sedimentation tank are simultaneously entered into the anaerobic tank of the AAO process for phosphorus release. Add Fe to the pool 2+ salt, Fe 2+ It reacts with the phosphorus in the anaerobic pool (the phosphorus carried by the influent and the phosphorus released by the phosphorus accumulating bacteria during the anaerobic process) to form blue iron ore crystals, and an anaerobic standing still connected to the anaerobic pool is provided at the back end of the anaerobic pool In the area, the mud-water mixture containing a large amount of blue iron ore enters the anaerobic static area for sedimentation and separation. Among them, the sludge containing a large amount of blue iron that settles at the bottom of the anaerobic static area is discharged through the sludge discharge pipe, and the b...

Embodiment 2

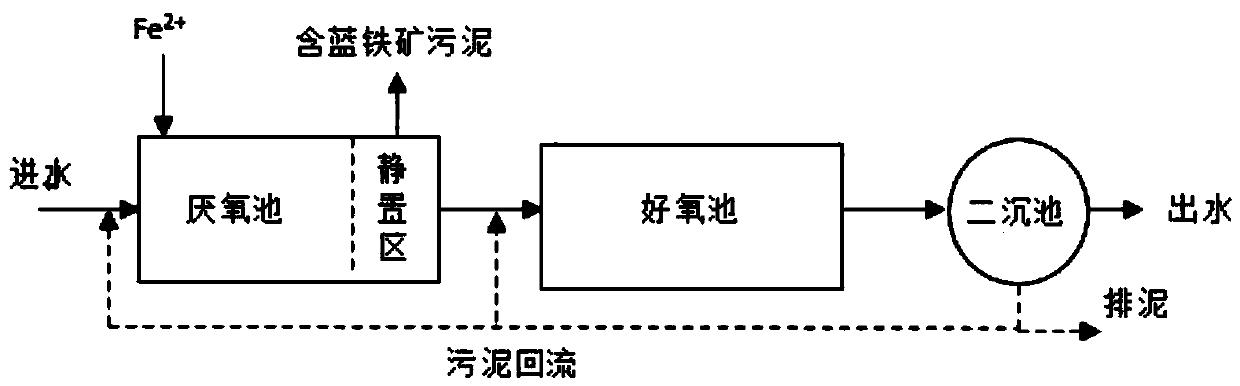

[0028] A pre-phosphorus removal method for blue iron ore crystallization based on the AAO process. The steps are: the raw sewage and all the sludge returned from the secondary sedimentation tank are simultaneously entered into the anaerobic tank of the AAO process for phosphorus release, and dosing in the anaerobic tank Fe 3+ salt, Fe 3+ It is reduced to Fe under the action of dissimilatory metal-reducing bacteria 2+ , Fe 2+ It reacts with the phosphorus in the anaerobic pool (the phosphorus carried by the influent and the phosphorus released by the phosphorus accumulating bacteria during the anaerobic process) to form blue iron ore crystals, and an anaerobic standing still connected to the anaerobic pool is provided at the back end of the anaerobic pool In the area, the mud-water mixture containing a large amount of blue iron ore enters the anaerobic static area for sedimentation and separation. Among them, the sludge containing a large amount of blue iron that settles at t...

Embodiment 3

[0031] A pre-phosphorus removal method for blue iron ore crystallization based on the AAO process. The steps are: the raw sewage and all the sludge returned from the secondary sedimentation tank are simultaneously entered into the anaerobic tank of the AAO process for phosphorus release, and dosing in the anaerobic tank Fe 2+ salt, Fe 2+ It reacts with the phosphorus in the anaerobic pool (the phosphorus carried by the influent and the phosphorus released by the phosphorus accumulating bacteria during the anaerobic process) to form blue iron ore crystals, and an anaerobic standing still connected to the anaerobic pool is provided at the back end of the anaerobic pool In the area, the mud-water mixture containing a large amount of blue iron ore enters the anaerobic static area for sedimentation and separation. Among them, the sludge containing a large amount of blue iron that settles at the bottom of the anaerobic static area is discharged from the system through the sludge dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com