Production method of smooth-surface domestic glass ceramic

A glass ceramics, production method technology, applied in glass production, glass pressing, glass forming and other directions, can solve problems such as product scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The daily-use glass-ceramic production method with smooth surface is characterized in that it comprises the following production steps:

[0024] (1) Production of semi-finished products

[0025] Using conventional production methods, the raw material of glass ceramics is smelted at 1400°C to form glass slurry, and the glass slurry is metered and put into a steel mold installed on a press, and pressurized to form a semi-finished product of daily-use glass ceramics;

[0026] (2) Flame polishing treatment of products

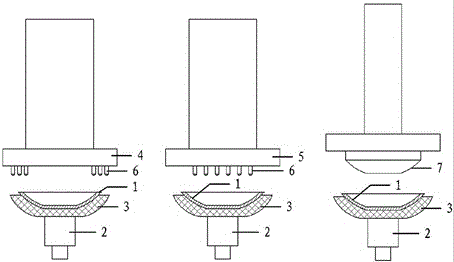

[0027] The semi-finished products are processed in the flame polishing room; the flame polishing room is equipped with a rotating disk, a graphite male mold and 2 combustion nozzles, and a supporting mold is set on the rotating disk, of which the flame nozzle of the No. The flame hole of the combustion nozzle is set in the middle, and the appearance of the graphite male mold is the same as the appearance of the inner cavity of the product;

[0028] Place t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com