A rotary magnetic fluid assisted grinding sleeve electrolytic composite processing device and method

A compound processing and magnetic fluid technology, which is applied in the field of rotary magnetic fluid assisted grinding sleeve electrolytic compound processing device, can solve the problems of damaged workpieces and high costs, reduce manufacturing costs, eliminate micro cracks, and improve process performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

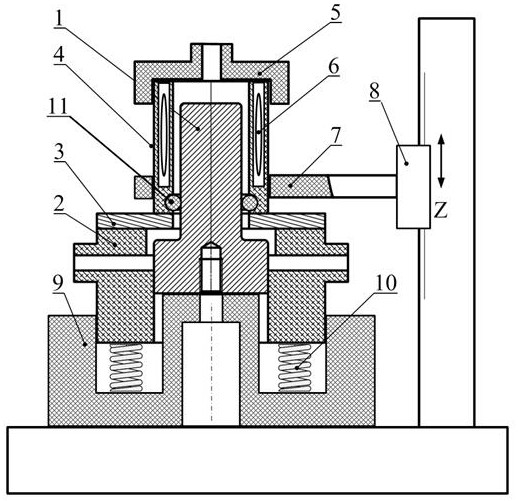

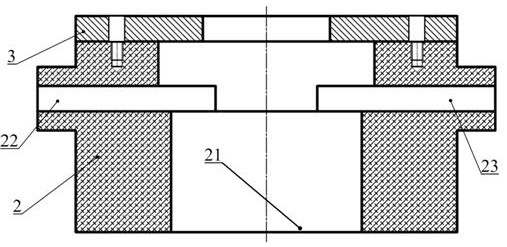

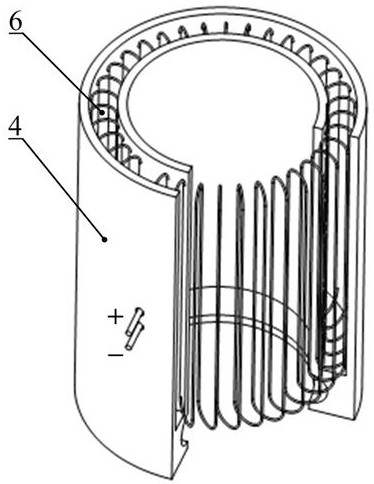

[0035] Combine below figure 1 , figure 2 and image 3 , illustrate the specific implementation process of the present invention:

[0036] A stepped through hole 21 is designed inside the insulating and sealing fixture 2, and the lower through hole of the stepped through hole 21 is used as the installation positioning hole of the workpiece 1;

[0037] The diameter of the upper through hole of the stepped through hole 21 is larger than the diameter of the lower through hole, which is convenient for the electrolyte solution to flow through;

[0038] The left and right sides of the insulating and sealing fixture 2 are respectively provided with a liquid inlet channel 22 and a liquid outlet channel 23; the electrolyte solution flows in at a high speed from the liquid inlet channel 22 and flows out from the liquid outlet channel 23, filling the first gap between the sheet alloy electrode 3 and the workpiece 1. Two annular gaps form the primary cell.

[0039] The sheet-shaped al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com