Indium oxide layer etchant composition and method for manufacturing array substrate of liquid crystal display device using same

A technology for liquid crystal display devices and array substrates, which is applied in the fields of chemical instruments and methods, surface etching compositions, semiconductor/solid-state device manufacturing, etc., and can solve the problems of lower layer damage, low lateral etching rate, and small side etching amount, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

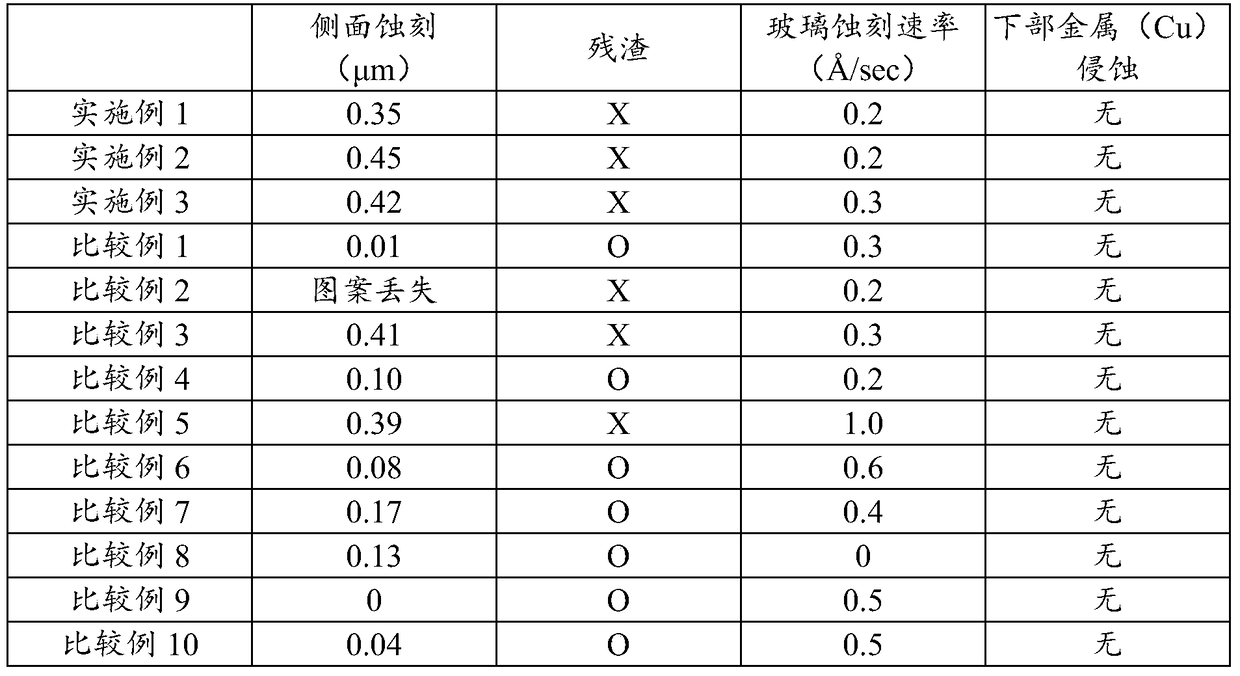

Embodiment 1 to 3 and comparative example 1 to 10

[0048] The indium oxide layer etchant compositions of Examples 1 to 3 and Comparative Examples 1 to 10 were prepared with the compositions shown in Table 1 below, and included the balance of water so that the total weight became 100% by weight.

[0049] 【Table 1】

[0050] (weight%)

[0051]

BTA

ABF

potassium sulfate

Ammonium acetate

Example 1

8

1.0

0.1

-

-

-

-

-

Example 2

15

1.5

0.1

-

-

-

-

-

Example 3

10

0.7

1.0

-

-

-

-

-

Comparative example 1

2

1.0

0.1

-

-

-

-

-

Comparative example 2

35

1.0

0.1

-

-

-

-

-

Comparative example 3

7

0.05

0.1

-

-

-

-

-

Comparative example 4

7

12

0.05

-

-

-

-

-

Comparative example 5

9

0.5

7

-

-

-

-

-

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com