Coke side small furnace end smoke treatment device

A flue gas treatment and burner technology, which is applied in coking ovens, climate change adaptation, climate sustainability, etc., can solve problems such as increased power consumption, smoke and dust escape, unsatisfactory results, etc., to achieve reduced consumption, wide range, The effect of improving the efficiency of flue gas collection and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

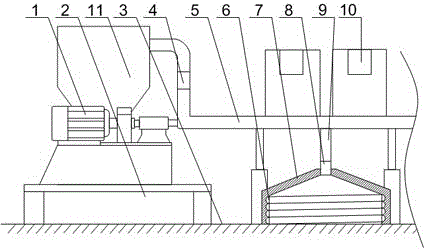

[0021] like figure 1 As shown, the present embodiment is provided with a supporting seat 2 on the base line 3 of the furnace top, on which the fan 1 and the dust collector 11 are fixed, and also includes a main air pipe 5 and a plurality of gas collecting hoods 7, the gas collecting The cover 7 covers the two adjacent coke-side small burners, and one end of the main air pipe 5 communicates with the air suction port of the blower fan 1 and the air inlet of the dust collector 11 respectively, and the other end of the main air pipe 5 communicates with the multiple air outlets through the bronchus 9. The two gas collection hoods 7 are connected; the gas collection hood 7 is composed of a collection section and a refraction section connected to each other. The collection section is cylindrical and has a spiral groove 6 on its inner wall along its axis direction. The refraction section is conical and its conical tip communicates with the end of the bronchi 9 . When working, a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com