Preparation process of novel high-hardness and high-flexibility composite polymer waterborne coating

A technology of composite polymer and water-based coatings, applied in coatings and other directions, can solve problems such as difficult to achieve 1H, poor solvent resistance, and reduced construction performance, and achieve better results, increase cross-linking density, and improve flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation process for a novel high-hardness and high-flexibility composite macromolecule water-based coating, comprising composite material D, purified water, wetting agent, leveling agent, hand feeling agent, water-based curing agent and fumed silica, characterized in that: The following components are prepared in parts by weight: 68% of composite material D, 10% of pure water, 1.5% of wetting agent, 0.5% of leveling agent, 2% of hand feeling agent, 15% of water-based curing agent and 3% of fumed silicon dioxide.

[0023] Preferably, its preparation steps are as follows:

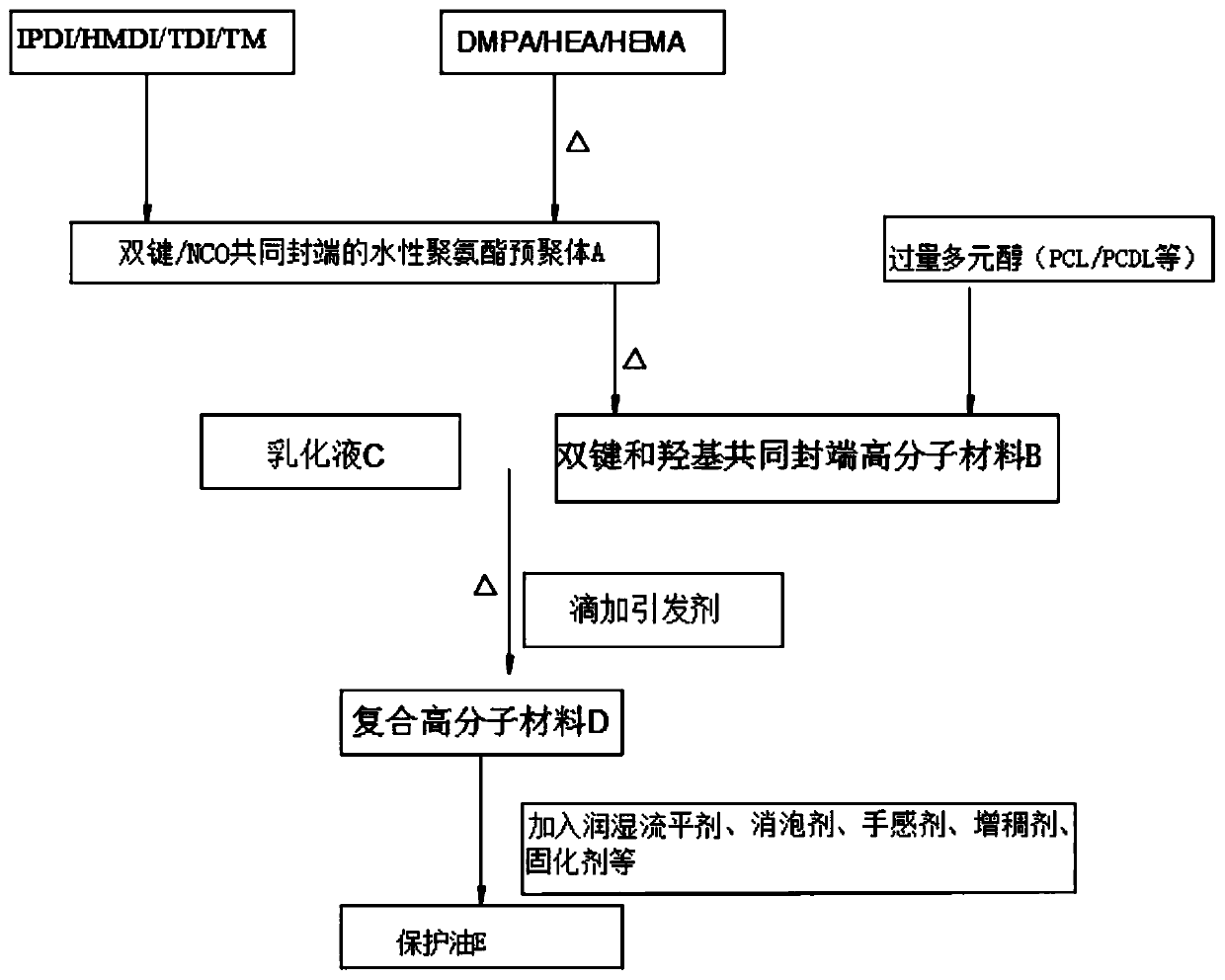

[0024] S1: Use methyl methacrylate, styrene and other monomers as solvents, heat to 85 degrees with IPDI / HMDI / TDI / TMI and DMPA, hydroxyethyl acrylate (HEA) / hydroxyethyl methacrylate (HEMA), Synthesize a kind of water-based polyurethane prepolymer A of double bond and NCO common termination;

[0025] S2: Heat the water-based polyurethane prepolymer A and excess polyol (PCL / PCDL / PTMEG / PPG, etc.) t...

Embodiment 2

[0034] A preparation process for a novel high-hardness and high-flexibility composite macromolecule water-based coating, comprising composite material D, purified water, wetting agent, leveling agent, hand feeling agent, water-based curing agent and fumed silica, characterized in that, by The following components are prepared by weight: 78% composite material D, 1% pure water, 1.5% wetting agent, 0.5% leveling agent, 2% hand feeling agent, 12% water-based curing agent and 5% fumed silica.

[0035] Preferably, its preparation steps are as follows:

[0036] S1: Use methyl methacrylate, styrene and other monomers as solvents, heat to 85 degrees with IPDI / HMDI / TDI / TMI and DMPA, hydroxyethyl acrylate (HEA) / hydroxyethyl methacrylate (HEMA), Synthesize a kind of water-based polyurethane prepolymer A of double bond and NCO common termination;

[0037]S2: Heat the water-based polyurethane prepolymer A and excess polyol (PCL / PCDL / PTMEG / PPG, etc.) to 95 degrees, and further polymerize t...

Embodiment 3

[0046] A preparation process for a novel high-hardness and high-flexibility composite polymer water-based coating, comprising composite material D, purified water, wetting agent, leveling agent, hand feeling agent, water-based curing agent and fumed silica, composed of the following parts by weight Components are prepared: 71% of composite material D, 5% of purified water, 1.5% of wetting agent, 0.5% of leveling agent, 2% of hand feeling agent, 10% of water-based curing agent and 2% of fumed silica.

[0047] Preferably, its preparation steps are as follows:

[0048] S1: Use methyl methacrylate, styrene and other monomers as solvents, heat to 85 degrees with IPDI / HMDI / TDI / TMI and DMPA, hydroxyethyl acrylate (HEA) / hydroxyethyl methacrylate (HEMA), Synthesize a kind of water-based polyurethane prepolymer A of double bond and NCO common termination;

[0049] S2: Heat the water-based polyurethane prepolymer A and excess polyol (PCL / PCDL / PTMEG / PPG, etc.) to 95 degrees, and further ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com