Electric deposition device for preparing high-resolution alpha source

An electrodeposition device and high-resolution technology, which is applied in the electrolysis process, electrolysis components, plating tanks, etc., can solve the problems of preparing high-resolution α sources, and achieve the effects of accelerated ion movement, small deposition thickness, and dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

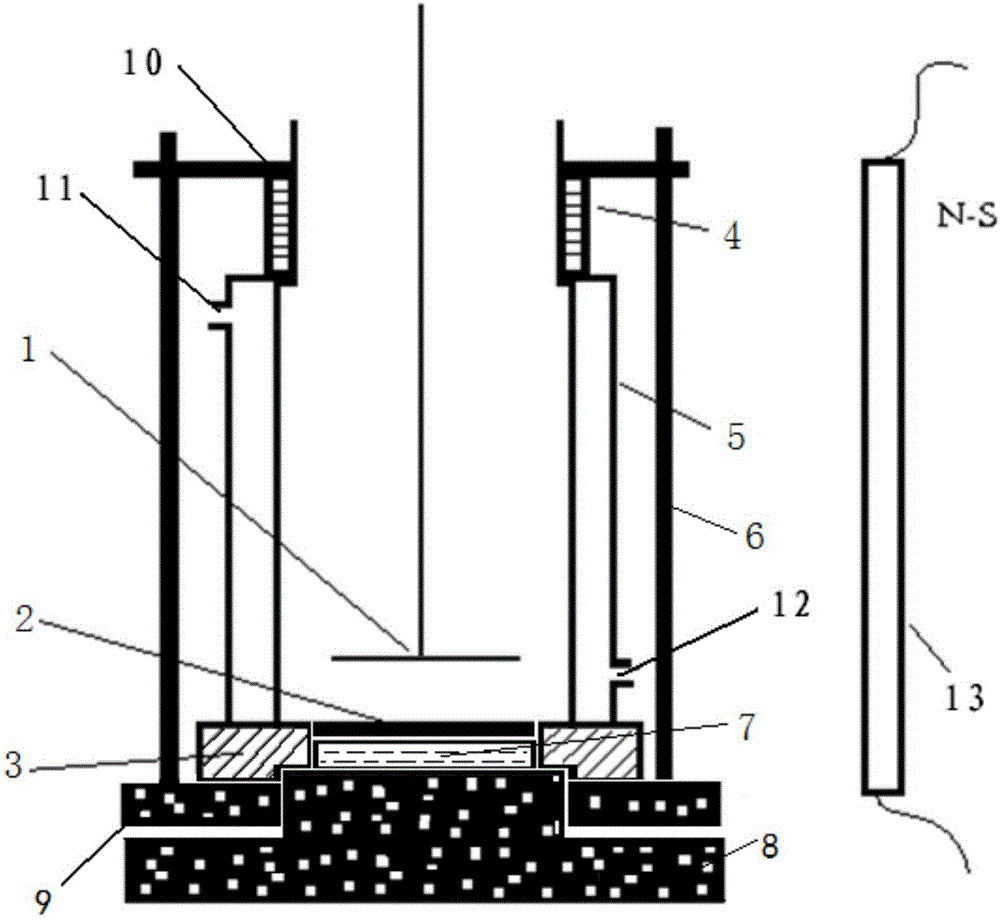

[0035] An electrodeposition device for preparing a high-resolution α source, the electrodeposition device includes a DC stabilized power supply, an electroplating tank 5, a bottom scale 2 made of stainless steel, a magnet 13 and a platinum electrode 1; the electroplating tank 5 The material is glass, which is a two-layer structure inside and outside, and the upper and bottom of the inner layer are provided with openings; the inner layer of the electroplating tank 5 is used to hold the electrodeposition plating solution, and the lower right corner of the outer layer is provided with a cooling circulating water inlet 12 , the upper left corner is provided with a cooling circulating water outlet 11; between the inner wall of the outer layer and the outer wall of the inner layer is the channel through which the cooling circulating water flows; the platinum electrode 1 is connected to the stirring motor, and the rotating speed of the platinum electrode 1 during the electrodeposition ...

Embodiment 2

[0044]Different from Example 1, the platinum electrode 1 extends from the radial center position of the upper end of the electroplating tank 5 to a position 1 cm away from the bottom of the electroplating tank; the bottom 2 is called silver; 1 at 60 rpm.

[0045] The magnetic field strength of the radial magnet relative to the center of the electroplating tank is 0.6T, and the distance from one side of the electroplating tank 5 is 3 cm.

Embodiment 3

[0047] Different from Example 1, the platinum electrode 1 extends from the radial center position of the upper end of the electroplating tank to the position 0.8 cm away from the bottom of the electroplating tank; the bottom 2 is aluminum; 1 at 50 rpm.

[0048] The magnetic field strength of the radial magnet relative to the center of the electroplating tank 1 is 1T, and the distance from one side of the electroplating tank is 1 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com